Reduce Supply Chain Carbon Emissions with Expert Strategies

Karel Maly

June 12, 2025

Understanding The Carbon Trail Hidden In Every Product

Imagine your morning coffee. Those beans journeyed thousands of kilometers before reaching your cup, leaving a trail of invisible carbon emissions. Supply chain carbon emissions are essentially the environmental footprint of a product’s entire life cycle. This journey starts with extracting raw materials, winds through manufacturing and packaging, includes transport and retail, and finally ends with disposal.

Think of a smartphone. Its carbon trail might start with rare earth mining in Africa, then move to component manufacturing in Asia, assembly in China, shipping across oceans, and finally distribution throughout the CZ region.

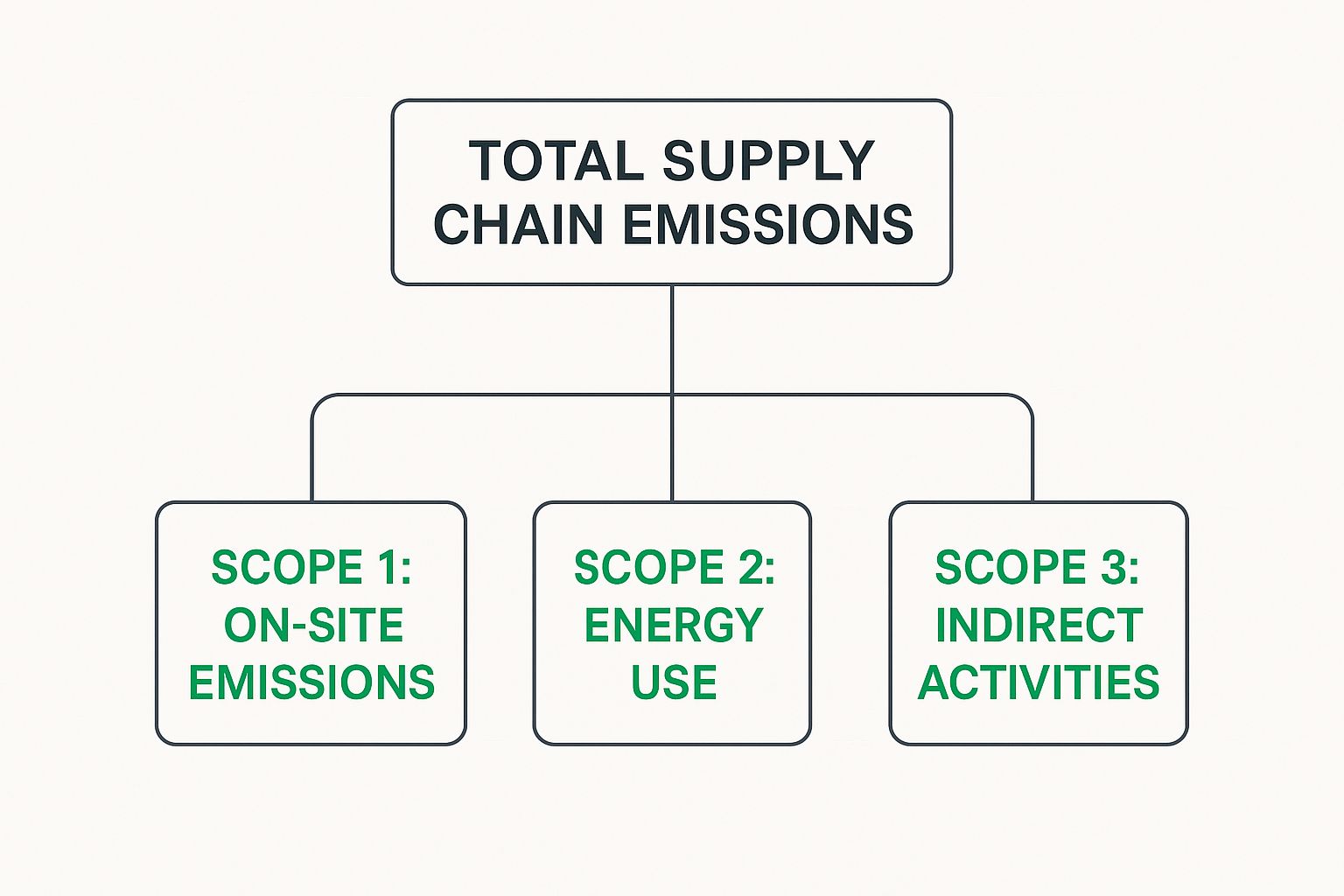

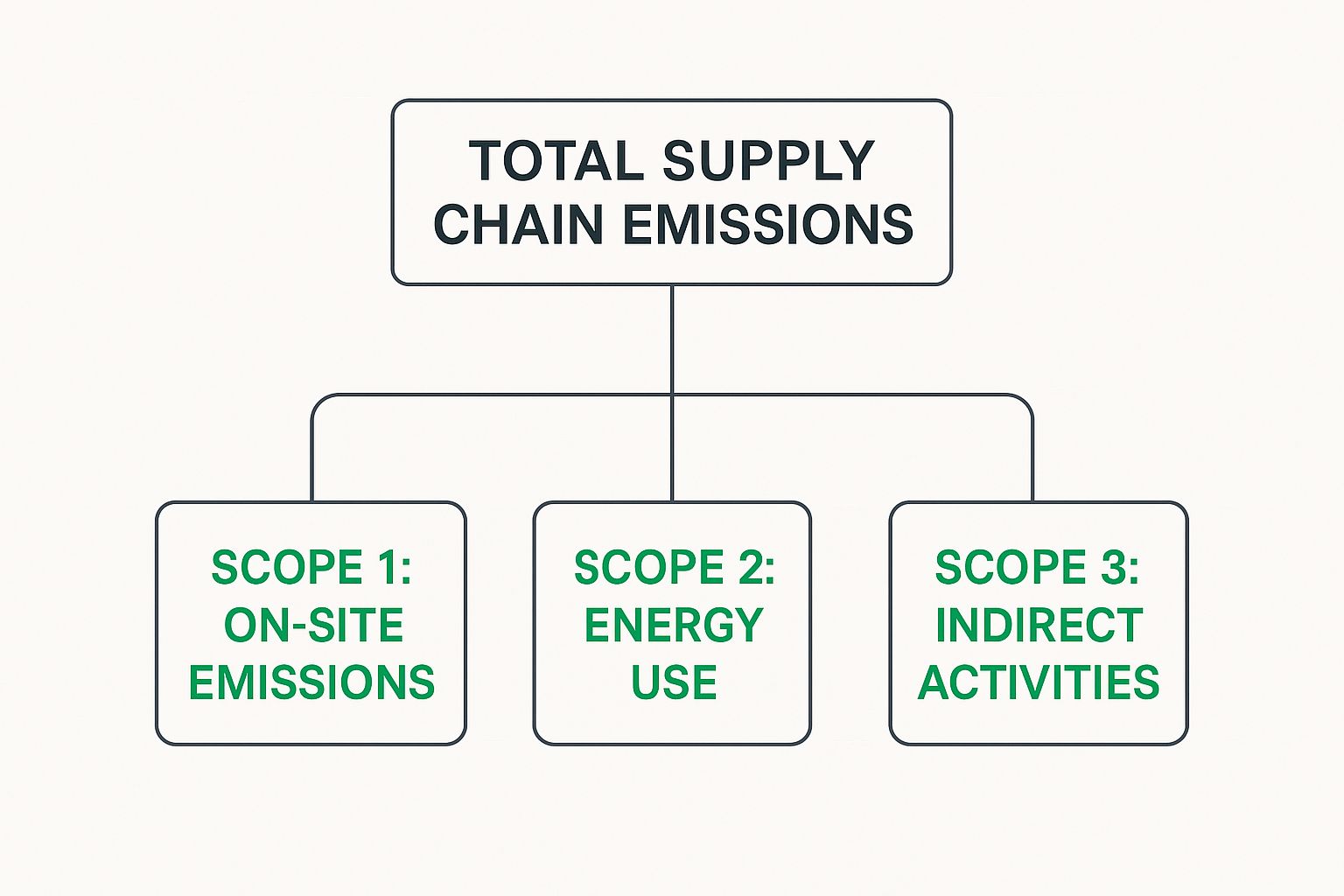

The infographic illustrates how total supply chain emissions are categorized: Scope 1 (direct on-site emissions), Scope 2 (emissions from purchased energy), and Scope 3 (indirect emissions from up and downstream activities). Notice how Scope 3 emissions, representing the entire supply chain, often comprise the largest portion of a company's carbon footprint. This highlights the need to look beyond a company’s immediate operations. You might be interested in: Read also: Carbon Footprint.

Why Do These Emissions Matter?

These often-overlooked emissions can be 5-10 times greater than a company’s direct emissions, making them a critical factor for businesses focused on environmental impact and competitive advantage. In the Czech Republic, carbon dioxide (CO2) is the primary greenhouse gas, accounting for 82.9% of total emissions in 2021. This emphasizes the urgent need to address CO2 emissions within supply chains, particularly in energy-intensive industries. Discover more insights about Czech Republic's emissions here. With the Czech Republic targeting 22% renewable energy by 2030, sustainability is clearly a growing priority within the CZ region.

Understanding these emissions isn’t just an academic exercise; it’s about pinpointing the biggest opportunities for positive change.

For example:

- Optimizing transportation routes

- Switching to sustainable packaging

- Working with suppliers to lower their emissions

These actions can significantly decrease a product’s overall carbon footprint.

To illustrate the different types of emissions, let's look at the following table:

Types of Supply Chain Carbon Emissions by Scope

A comprehensive breakdown of Scope 1, 2, and 3 emissions with practical examples from different industries

| Emission Scope | Description | Industry Examples | Typical % of Total |

|---|---|---|---|

| Scope 1 | Direct emissions from owned or controlled sources. | Burning fossil fuels in company vehicles, on-site manufacturing processes. | Can vary widely depending on industry, but generally a smaller percentage than Scope 3. |

| Scope 2 | Indirect emissions from the generation of purchased energy. | Electricity consumed in offices, factories, and retail stores. | Generally a smaller percentage than Scope 3. |

| Scope 3 | Indirect emissions (not included in Scope 2) that occur in the value chain of the reporting company. | Emissions from goods and services purchased, transportation of goods, business travel, waste disposal. | Often represents the largest portion (70-90%) of a company's total emissions. |

This table shows how Scope 3 emissions often dominate a company's carbon footprint, highlighting the importance of engaging with the entire supply chain.

This screenshot from Wikipedia's Carbon Footprint page offers a helpful summary of the concept, emphasizing its relevance to individuals, organizations, and products. The key point is that every activity, from driving a car to manufacturing goods, creates a carbon footprint. By understanding and measuring these footprints, we can effectively manage and reduce them.

The Strategic Importance of Understanding Your Carbon Trail

Understanding the carbon trail isn’t just about environmental stewardship; it's rapidly becoming a core business strategy. This shift is driven by changing regulations, evolving consumer expectations, and the growing understanding that sustainability can drive innovation and cost savings. This leads us to explore why leading companies are now prioritizing supply chain emissions as a strategic imperative.

Why Smart Companies Treat This As a Strategic Priority

Forward-thinking companies in the CZ region are realizing that managing supply chain carbon emissions isn't just a box to tick—it's a core element of long-term success. Think of it like navigating a ship: those who chart a course for emissions are better prepared for rough seas like regulatory changes, evolving customer demands, and a competitive market.

The Business Case for Emission Management

Let's compare two companies: one actively manages emissions, the other doesn't. The first company spots energy waste, streamlines its delivery routes, and works with its suppliers to reduce their environmental impact. The result? Lower energy and transport costs, and stronger relationships with suppliers.

The second company, however, faces rising energy costs, penalties for not following regulations, and pressure from customers who want greener products. This translates to higher overall costs, damage to their reputation, and lost business.

This contrast highlights why smart companies prioritize supply chain carbon emissions: it builds resilience, reduces risk, and creates opportunities for growth. Investors are increasingly examining companies' climate strategies, and big customers want emission reports from their suppliers. Companies who act early gain a real competitive edge, attracting environmentally conscious customers and accessing green financing.

The Czech economy, with its high carbon footprint and high greenhouse gas emissions per unit of GDP (among the highest in OECD countries), presents a particular challenge. But this challenge also represents a major opportunity for companies to stand out by managing emissions effectively. Want to explore this further? Discover more insights

Turning Emission Reduction into Profit Drivers

The idea that sustainability always means higher costs is disappearing fast. Many companies find that reducing emissions can actually increase profits. Optimizing logistics, for instance, can cut fuel use and transport costs. Investing in energy-efficient technology can lower energy bills. These savings go straight to the bottom line, proving that environmental responsibility and financial performance can work together.

This screenshot from the Carbon Trust website highlights their work helping businesses reduce their environmental footprint and use resources more efficiently. The Carbon Trust offers a range of services, reflecting the growing support available to companies on their decarbonization journey. Their expertise underscores the growing recognition of how vital managing carbon emissions is for business success.

The Future of Competitive Advantage

Supply chain carbon emissions are no longer a niche environmental issue; they're a mainstream business priority. They affect everything from supplier partnerships to market access. Companies that incorporate emission management into their core strategy aren't just doing good for the planet; they're setting themselves up for long-term success in a competitive market that values sustainability. This proactive approach isn't just about reducing negative impacts; it’s about creating positive value for the business, the environment, and the future of the CZ region.

Making The Invisible Measurable: Practical Approaches

Measuring your supply chain's carbon emissions can seem daunting, like trying to catch smoke. But many companies are successfully doing it, using established methods that resemble detective work – gathering clues to piece together your carbon footprint.

Practical Measurement Approaches

Different companies use various practical approaches. Some work directly with their suppliers to get firsthand information. Others use advanced modeling tools to map complex supply networks. The best approach depends on factors like the complexity of your supply chain and the resources you have available.

-

Primary Data Collection: This involves working directly with your suppliers to get emission data. Think of it like interviewing witnesses at a crime scene. You're gathering firsthand accounts through questionnaires, audits, and even site visits. While this is the most accurate method, managing this across a large network of suppliers can be time-consuming and costly.

-

Life Cycle Assessments (LCAs): LCAs examine a product’s environmental impacts from beginning to end – from its "cradle" to its "grave," including all emissions generated along the way. These assessments are extremely detailed, like a full forensic analysis, but they require specialized expertise and a lot of data.

-

Input-Output Modeling: This method uses economic data and emission factors to estimate emissions across entire industries. It's like looking at the overall crime statistics of a city to get a general sense of the problem, but it lacks the detail of investigating individual cases. It's useful for high-level estimations but not for granular insights.

-

Hybrid Approaches: Many companies combine these methods. They might collect primary data from their most important suppliers and use input-output modeling for the others. This balanced approach offers reasonable accuracy while making efficient use of resources.

Setting Boundaries and Prioritizing

Imagine trying to account for the emissions of every single component of your product. Overwhelming, right? This is why companies set measurement boundaries to define the scope of their analysis. They might focus on specific product lines, certain geographic regions, or particular tiers of their suppliers.

Prioritization is essential. Companies often start by focusing on their highest-impact suppliers and processes. A clothing company might prioritize fabric production (a significant source of emissions) over packaging, for instance. This focused approach achieves the biggest impact with the resources available.

This screenshot from the Greenhouse Gas Protocol website illustrates their framework for corporate emissions accounting and reporting. It provides a structured approach, allowing businesses to quantify and manage their emissions. The key takeaway is the emphasis on different emission scopes (Scopes 1, 2, and 3) and the readily available resources for implementation.

Building Reliable Data Collection Systems

Consistent data is crucial for tracking progress. Companies develop systems to monitor emissions over time, allowing them to identify areas for improvement. This might involve integrating emissions data into existing Enterprise Resource Planning (ERP) systems or using specialized software like CarbonChain.

Addressing Common Challenges

Measuring supply chain emissions comes with its challenges:

-

Supplier Cooperation: Getting suppliers on board can be tricky. Some may not be ready or willing to share their data. Building strong relationships, offering support, and highlighting the mutual benefits of transparency are key.

-

Incomplete Data: Data gaps are common. Using industry averages, proxy data, or emission factors can fill these gaps until more accurate data becomes available.

-

Resource Constraints: Measuring emissions takes time, personnel, and resources. Start small, prioritize key areas, and gradually expand the scope over time.

Companies everywhere face these challenges. Finding practical, cost-effective solutions tailored to their specific circumstances is vital. This could involve working with local experts or using industry-specific emission databases.

Practical Example: A Czech Furniture Manufacturer

A furniture manufacturer in the Czech Republic wants to measure its supply chain emissions. They begin by focusing on their biggest suppliers of wood, textiles, and packaging. They work directly with these suppliers to gather primary data on energy use and emissions. For smaller suppliers, they use industry averages from Czech-specific data sources and input-output modeling for transportation emissions. This combined method provides a realistic starting point.

To help clarify the different measurement methods, here’s a comparison table:

| Method | Accuracy Level | Cost Range | Implementation Time | Best For |

|---|---|---|---|---|

| Primary Data Collection | High | High | Long | Key suppliers, critical emission sources |

| Life Cycle Assessments (LCAs) | High | High | Long | Detailed product-level analysis |

| Input-Output Modeling | Low | Low | Short | High-level industry estimates, screening |

| Hybrid Approaches | Medium | Medium | Medium | Balancing accuracy and resource constraints |

This table provides a quick overview of each method’s strengths and weaknesses. It allows companies to quickly assess which approach aligns best with their needs and resources.

By taking a practical, step-by-step approach, businesses can gain valuable insights into their supply chain carbon emissions. This understanding isn't just good for the planet – it's also a crucial factor for long-term success.

Navigating Regulations Without Losing Your Mind

The world of supply chain carbon emissions regulations is constantly changing, creating both hurdles and opportunities. For businesses in the CZ region, understanding these regulations isn't just about checking boxes for compliance. It's about using them strategically to your advantage. Forget drowning in legal jargon; this is about grasping the real-world impact on your daily operations and long-term plans.

Key Regulatory Trends

Several important trends are shaping the regulatory landscape for supply chain carbon emissions:

-

EU's Corporate Sustainability Reporting Directive (CSRD): Think of the CSRD as a giant magnifying glass on sustainability. It significantly expands what companies operating in the EU must report regarding environmental, social, and governance (ESG) factors, including those pesky supply chain carbon emissions. This means greater transparency and accountability.

-

Carbon Border Adjustment Mechanisms (CBAMs): Imagine a carbon tax applied to imported goods. That’s essentially what CBAMs are. They aim to level the playing field between goods produced within the EU and those imported from countries with less strict environmental policies. This has huge implications for companies in the CZ region importing goods into the EU.

-

Sector-Specific Requirements: Some industries, like energy and transportation, face extra regulations specifically targeting their emissions. If your business operates in one of these sectors, understanding these specific rules is critical.

This screenshot from the European Commission website highlights the CSRD and its goal to improve how sustainability information flows in the corporate world. The page offers details about the directive, who it applies to, and what it means for businesses. The takeaway? Transparency is paramount, and companies need to bake sustainability reporting into their core operations.

Turning Compliance into a Competitive Advantage

Forward-thinking companies aren’t just reacting to regulations; they’re anticipating them. They’re turning compliance into a strategic advantage, like reinforcing the foundation of their business. By putting strong emission tracking and management systems in place, companies can:

-

Attract Investors: More and more, investors are prioritizing ESG factors, including supply chain emissions, when deciding where to put their money. Companies with a solid sustainability record are more appealing to investors.

-

Win New Customers: Consumers are increasingly eco-conscious. They’re demanding greener products. Companies that can demonstrate a commitment to reducing supply chain emissions gain a real edge.

-

Reduce Costs: By finding and fixing inefficiencies in their supply chains, companies can lower their energy use and transportation costs, leading to real savings.

Timeline Considerations and Regional Differences

Regulations don't just magically appear. They are usually rolled out in phases, giving companies time to adjust. The CSRD, for example, will be implemented gradually over the next few years, with different requirements for different company sizes and sectors. Knowing these timelines helps with strategic planning. Regional differences also matter. While the EU is often a leader in this area, other regions are creating their own regulations. Companies with global supply chains need to understand these variations and adapt accordingly.

Building Scalable Compliance Systems

You need compliance systems that can evolve with changing regulations. This means using systems that can:

-

Collect and Track Emissions Data: This requires reliable data collection, ideally automated through tools like Carbonpunk.

-

Generate Reports: Compliance often means regularly reporting emissions data to regulators and other stakeholders. Automating this simplifies the process.

-

Adapt to New Requirements: Regulations change. Your systems should be flexible enough to handle new data points and reporting demands.

Real-World Examples

Companies in the CZ region and elsewhere are successfully navigating these regulatory waters. Some Czech manufacturers, for instance, are collaborating with their suppliers to gather emissions data and implement reduction strategies. These companies aren't just meeting requirements; they're also strengthening their supply chains, boosting their reputations, and improving their bottom line. This proactive approach to compliance turns it from a burden into a chance for growth and innovation. It's about building practical, scalable systems that work now and are ready for what’s next, creating a more sustainable and successful business for the long haul.

Building Management Systems That Actually Drive Results

Imagine stepping on a scale. It tells you your weight, which is useful information. But it doesn't tell you how to lose weight. That's where a good fitness plan comes in. Similarly, having emissions data is important, but it's only the starting point. The real value lies in building management systems that translate that data into meaningful action.

Setting Science-Based Targets

Any good fitness plan starts with a goal. Instead of aiming for an arbitrary weight loss number, what if you based your goal on what health experts recommend? That's the idea behind science-based targets for emissions. They provide a structured approach to decarbonization, aligned with the latest climate science. They aren't just vague aspirations; they are specific, measurable, achievable, relevant, and time-bound – just like a well-structured workout routine.

The Science Based Targets initiative (SBTi) offers a robust framework for setting these targets. Their website provides a wealth of resources to guide companies. It’s like having a personal trainer for your company’s decarbonization journey.

Engaging Suppliers Effectively

Think of your suppliers as workout buddies. You wouldn't yell at your buddy to lift heavier weights; you'd encourage and support them. Similarly, engaging your suppliers through training programs, best practice sharing, and incentives can foster a collaborative approach to emission reduction. It’s about working together towards a shared goal.

Building Internal Capabilities

Getting in shape requires building muscle, which takes time and consistent effort. Likewise, reducing emissions requires building internal capabilities. This means training your employees, establishing dedicated sustainability teams, and integrating emission management into your everyday operations. It’s a long-term commitment, not a quick fix.

Prioritizing for Maximum Impact

Just as some exercises are more effective than others, some emission reduction strategies yield greater results. Prioritization frameworks help you identify the "low-hanging fruit"—actions that deliver the biggest impact with the least effort. For instance, optimizing transport routes can be a highly effective starting point, offering significant gains without requiring substantial investments in new technology.

Consider the Czech Republic's industrial sector, a major contributor to the country's carbon footprint. While emissions have decreased since 1990, there's still significant room for improvement. Learn more about the Czech Republic's carbon footprint. Strategic prioritization is crucial for maximizing the environmental and financial returns of emission reduction efforts. For further insights, check out our guide on ESG Reporting.

Adapting to Different Industry Contexts

Different workouts suit different body types. Similarly, the best emission management approach varies across industries. A heavy manufacturing plant faces different challenges and opportunities than a retail company. While the core principles of science-based targets, supplier engagement, and internal capability building remain consistent, the implementation needs to be tailored to each industry’s specific context.

Embracing Continuous Improvement

Fitness is a journey, not a destination. You constantly adjust your workout routine based on your progress and changing needs. The same principle applies to managing emissions. Embrace a continuous improvement mindset, adapt to new regulations and best practices, and always strive for better performance. This creates a positive feedback loop: environmental responsibility strengthens your business, and a stronger business enables further environmental improvements.

Learning From Companies Who've Cracked The Code

Sometimes, the best learning comes from seeing how others succeed. Let's explore some inspiring examples of companies – big and small, across various industries – that have successfully tackled their supply chain carbon emissions.

Transforming Supplier Relationships and Slashing Emissions

Imagine a global manufacturer reducing emissions by 40% and saving money. It's not a pipe dream. One manufacturer completely revamped their approach to supplier relationships. They fostered collaboration to pinpoint emission hotspots and implement effective changes. Instead of simply imposing demands, they provided support and resources, effectively turning suppliers into partners on their sustainability journey. This strategy didn't just lower emissions; it also boosted the manufacturer's overall supply chain efficiency and resilience.

Optimizing Transportation for a Greener Bottom Line

A retailer grappled with a familiar challenge: how to move goods efficiently while minimizing their environmental impact. Their solution? Transportation optimization. By leveraging technology to map the most efficient routes, consolidate shipments, and transition to lower-emission transport (like rail or electric vehicles), they significantly reduced fuel consumption and CO2 emissions. And there's more: these changes also lowered transportation costs, proving that sustainability can be profitable.

The Journey to Carbon-Neutral Operations

A technology company set an ambitious goal: carbon-neutral operations. They began by meticulously measuring their entire supply chain's carbon footprint, identifying the biggest emission culprits. Then, they implemented a multi-pronged approach:

-

Renewable Energy Procurement: Switching to renewable energy sources for their operations minimized their reliance on fossil fuels.

-

Supplier Engagement: Working closely with suppliers to reduce emissions across their operations, they offered incentives and support for adopting sustainable practices.

-

Carbon Offsets: To neutralize remaining emissions, they invested in verified carbon offset projects, like reforestation and renewable energy development.

This comprehensive approach showcased their dedication to a carbon-neutral future, attracting investors and customers who value sustainability.

This screenshot from the CDP website highlights their work on supply chain engagement, emphasizing its importance in achieving climate goals. CDP's focus on transparency and data-driven insights demonstrates the growing importance of accurate supply chain emissions reporting for investors and stakeholders. The key takeaway? Collaboration is powerful. Effective climate action requires companies to work together across their entire supply chain.

Lessons Learned: Overcoming Obstacles and Achieving Results

These aren't just neatly packaged success stories. These companies encountered real hurdles:

-

Supplier Resistance: Initially, not all suppliers embraced the proposed changes.

-

Data Gaps: Gathering accurate emissions data can be challenging, especially with complex supply chains.

-

Resource Constraints: Implementing new systems and processes requires investment and dedicated resources.

However, they overcame these obstacles by:

-

Building Strong Relationships: They fostered open communication and collaboration with their suppliers, highlighting the shared advantages of reducing supply chain emissions.

-

Finding Practical Solutions: They used available tools and resources, such as industry-specific emission databases and expert consultants, to address data gaps and manage resource limitations.

-

Integrating Sustainability into Core Operations: They embedded emission management into their core business strategy, not treating it as a separate environmental initiative. This integration ensured long-term sustainability and resilience.

These companies didn't just lessen their environmental impact; they also improved their bottom line, strengthened their brand reputation, and gained a competitive edge. Their experiences offer practical strategies that businesses of all sizes, across all sectors, can adapt to their specific needs. They demonstrate that managing supply chain carbon emissions isn't just about environmental responsibility; it's about building a more sustainable and successful future.

Your Practical Roadmap For Moving Forward

Understanding supply chain carbon emissions is essential, but true progress requires a well-structured plan. Think of it like planning a road trip: you wouldn't just hop in the car and start driving without knowing your destination or checking the route, would you? This section provides a practical roadmap to help you navigate your journey toward reducing supply chain emissions. Whether you're just starting to think about your carbon footprint or looking to improve existing programs, you'll find helpful guidance here.

Building a Strong Foundation

Before you hit the accelerator, you need to know where you're starting from. Assess your current situation. Are you at the beginning of your sustainability journey, just starting to measure your emissions? Or do you already have initiatives in place? This initial assessment will shape your next steps. It’s like checking your map before you start your journey.

Next, gather support within your organization. Talk to key stakeholders about why reducing supply chain carbon emissions makes good business sense. Explain the potential cost savings, reduced risks, and opportunities to improve your brand image. Getting everyone on board is like ensuring everyone in the car agrees on the destination.

Choosing the Right Tools and Partners

Just as you need the right car for a road trip, choosing the right tools and partners is crucial for your emissions reduction journey. Think about your specific needs and the context of your industry. Do you need powerful software for in-depth Life Cycle Assessments (LCA)? Or would a simpler carbon footprint calculator do the job? Explore potential partnerships with environmental consultants, technology providers, and industry associations. For a helpful resource, check out our guide on using a carbon footprint calculator.

Creating Accountability and Overcoming Challenges

To stay on track, you need clear accountability systems. Define roles and responsibilities, set targets, and monitor your progress. Regularly communicate updates to stakeholders and celebrate milestones along the way. This is like checking your progress on the map and making sure everyone in the car is happy with the journey.

Implementing any new initiative comes with challenges, like limited resources or resistance from suppliers. Be proactive. Offer support and incentives to encourage your suppliers to participate. Start with pilot projects to show how emission reduction initiatives work and the benefits they offer. Build internal skills through training and knowledge sharing.

Delivering Quick Wins and Building Momentum

Plan for some early successes to gain momentum and show the value of your efforts. For example, optimizing transportation routes can lead to immediate fuel savings and lower emissions. These quick wins are like reaching a scenic viewpoint early in the road trip – they keep everyone motivated for the rest of the journey.

Establishing a Framework for Long-Term Success

While quick wins are great, you also need a plan for long-term success. Develop a comprehensive strategy that aligns with your business objectives and your sustainability goals. Integrate emissions management into your core business operations, rather than treating it as a separate project. This is like ensuring your road trip is part of a larger plan, and not just a one-off excursion. This approach will ensure sustainability is woven into the fabric of your company culture and drives continuous improvement.

By following this roadmap, you can reshape your approach to supply chain carbon emissions, creating long-term value for your business and the environment. Ready to get started? Explore Carbonpunk, the AI-driven carbon management platform, to streamline your journey towards a sustainable supply chain.