Supply Chain Visibility to Reduce Cost and Emissions Guide

Karel Maly

September 5, 2025

Using supply chain visibility to cut costs and emissions isn't just a smart move; it's a direct path to being more profitable and sustainable. When you have real-time data at your fingertips, you can stop reacting and start making proactive decisions that slash fuel consumption, get rid of waste, and make your whole operation run smoother. It turns a complex, unpredictable logistics network into a finely tuned competitive advantage.

The High Cost of Operating in the Dark

Picture an orchestra trying to play a symphony, but without a conductor. Every musician is a pro—your suppliers, carriers, and warehouses all know their part. But without a shared sheet of music or someone to set the tempo, you get chaos. Cues are missed, effort is wasted, and the final performance is a mess.

That's what it’s like for so many businesses running with poor supply chain visibility. This operational "darkness" creates a domino effect of expensive problems that eat into your profits and bloat your carbon footprint. When you can’t see where your goods are at any given moment, you're always playing catch-up instead of planning ahead.

The Financial and Environmental Toll of Blind Spots

The fallout from this chaos hits you both immediately and in the long run. Without a clear line of sight across your operations, you’re stuck with inefficiencies that hurt your bank account and the planet.

- Excess Fuel Consumption: Drivers end up on less-than-ideal routes or sit idling for hours at congested ports, burning fuel for no good reason and pumping out emissions that could have been avoided.

- Spoiled and Wasted Goods: For temperature-sensitive products like food or pharmaceuticals, an unexpected delay can mean an entire shipment is ruined. That's a total loss of the product, plus all the resources and embedded carbon that went into making it.

- Sky-High Emergency Costs: When you can't see a problem coming, you're constantly paying for last-minute, expedited shipping to prevent stockouts or meet a customer deadline.

A supply chain without visibility is like driving at night with the headlights off. You might be moving forward, but you’re heading for an inevitable and expensive accident. Gaining visibility is about turning on those lights to navigate risks and seize opportunities.

To see the real-world difference, let's compare what happens when a business operates with low versus high visibility.

Impact of Low vs. High Supply Chain Visibility

| Business Area | Result of Low Visibility | Benefit of High Visibility |

|---|---|---|

| Logistics & Transport | Inefficient routes, high fuel use, excessive idling. | Optimised routes, 15% reduction in fuel costs, less idle time. |

| Inventory Management | Overstocking to avoid shortages, high carrying costs. | Just-in-time inventory, reduced safety stock, lower warehousing costs. |

| Customer Service | Inaccurate delivery estimates, frequent delays, poor communication. | Proactive delay alerts, precise ETAs, improved customer trust. |

| Risk Management | Slow reaction to disruptions (e.g., port closures, weather). | Ability to reroute shipments proactively, minimising impact. |

| Sustainability | High, unmeasured carbon footprint from wasted resources. | Accurate emissions tracking, targeted reduction strategies. |

As the table shows, the shift from guesswork to informed decision-making is significant. Better visibility isn't a minor tweak; it's a fundamental change that delivers tangible benefits across the board.

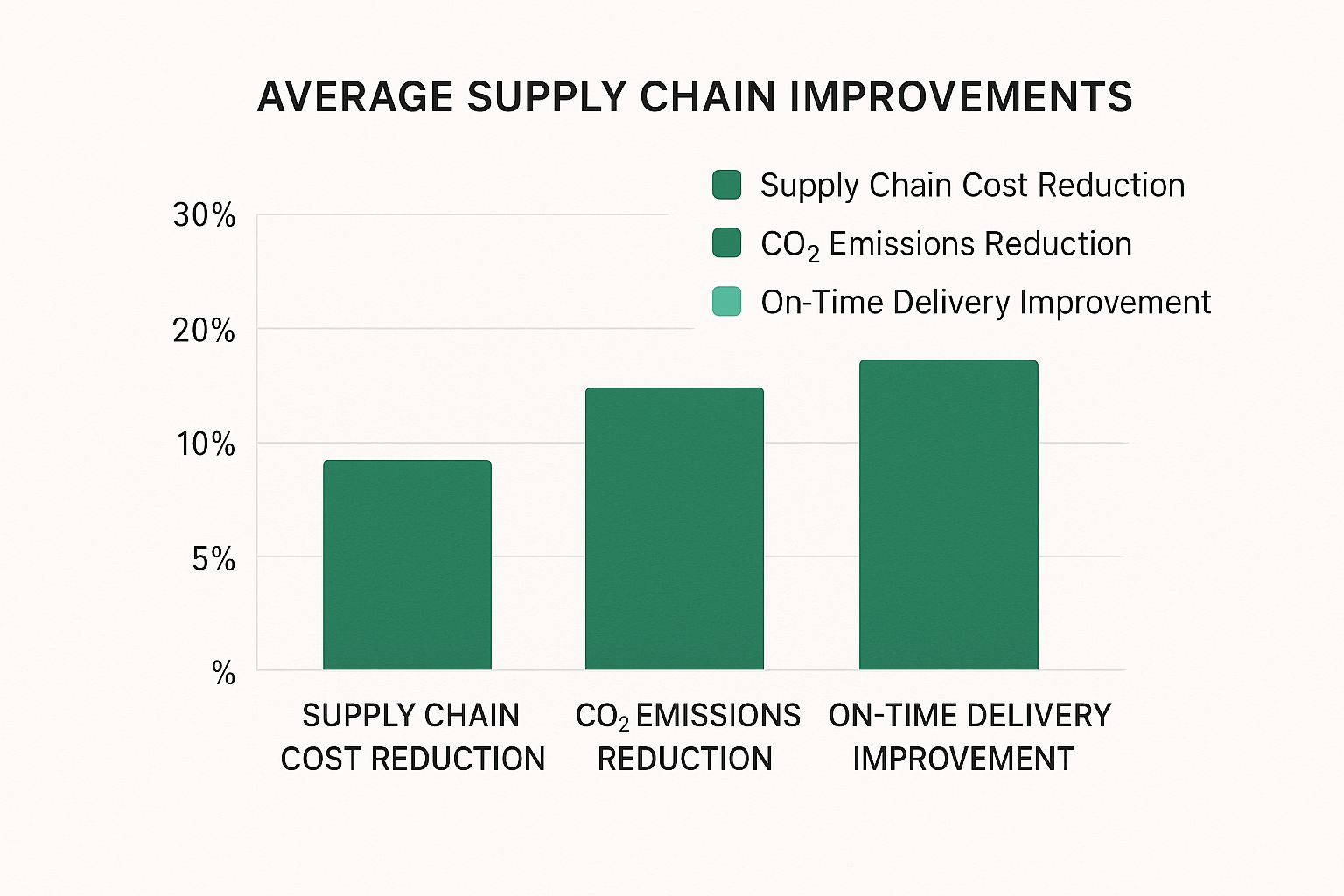

The chart below paints an even clearer picture of just how powerful this shift can be for your key metrics.

The data speaks for itself: improving visibility delivers major wins for your costs, emissions, and service levels all at once. True supply chain visibility isn’t just about seeing dots on a map. It’s about gaining the intelligence to run a smarter, leaner, and greener logistics network—turning potential chaos into a profitable, well-oiled machine.

Understanding True Supply Chain Visibility

Let's cut through the jargon around ‘supply chain visibility’. Think about the difference between an old paper map and a live GPS. The map shows you the intended route, but the GPS shows you what’s actually happening on the road right now—traffic jams, weather alerts, and accidents included.

This live view doesn't just show your location; it helps you make better decisions on the fly. It finds a detour around that sudden gridlock, adjusts your arrival time based on current speed, and helps you navigate unexpected roadblocks. This is precisely what modern supply chain visibility to reduce cost and emissions does for your business.

It’s about shifting from a reactive mindset, where you only hear about problems after they've already caused delays, to a proactive one. You can see issues coming and manage them before they ever disrupt your operations.

Beyond Dots On A Map

Real visibility is much more than just knowing where a truck is. It’s about gaining a complete, end-to-end picture of your entire logistics network as it happens. This means you have access to detailed data from the moment a supplier ships raw materials to the second a finished product arrives at your customer's door.

This level of insight weaves countless data points into a single, clear story. It lets you answer crucial questions in an instant:

- Where is my shipment right now? This is the most basic layer of tracking.

- Is it on schedule? You can compare its real-time progress against the original plan.

- What condition are the goods in? For sensitive items, you can monitor things like temperature or humidity.

- What is the carbon footprint of this journey? Emissions are calculated using the actual route, vehicle, and fuel data.

Answering these questions transforms what used to be a long, unpredictable chain of events into a predictable and manageable process.

Gaining true visibility means transforming your supply chain from a series of disconnected handoffs into a unified, intelligent ecosystem. It’s the difference between guessing what might happen and knowing what will happen next.

Turning Data Into a Competitive Advantage

When you can see your entire supply chain clearly, you can start optimising every part of it. This newfound clarity fuels quick, smart decisions that have a direct impact on both your bottom line and your environmental goals.

We see this happening right here in the Czech Republic with the adoption of Industry 4.0. Local manufacturers who have implemented IoT networks have seen their supply chain transparency improve by up to 92%. This seamless flow of real-time information has produced real results, including a 40% drop in maintenance costs and a 20% increase in equipment lifespan. Visibility directly builds financial and operational resilience.

Of course, all this data is useless if you can't understand it. A crucial step is presenting it in a clear, actionable format. To learn a practical way to make your supply chain data work for you, see how to create a KPI dashboard.

Ultimately, achieving this level of insight is no longer a "nice-to-have." For a more detailed perspective, check out our guide on mastering supply chain visibility for your business. It is the essential foundation for building a logistics operation that is efficient, cost-effective, and truly responsible.

How Visibility Slashes Your Operational Costs

Seeing your supply chain clearly does more than just track a dot on a map; it actively plugs the financial leaks that drain your profits. Let's move beyond the buzzwords and look at exactly how this clarity cuts your operational costs and makes every logistics pound work smarter for you.

The first and most immediate win is a massive reduction in inventory carrying costs. Most companies are forced to hold huge amounts of "just-in-case" safety stock, a costly buffer against delays they can't see coming. This practice ties up a ton of capital and racks up expenses for storage, insurance, and the risk of goods becoming obsolete. With precise, real-time data, you can finally shift to a leaner, just-in-time model with confidence, eliminating the need for those bulky, expensive reserves.

This data-first approach completely changes how your warehouse operates. Instead of a vague "sometime on Tuesday" arrival, your team knows a shipment will arrive within a specific hour. This allows for perfect staffing—no more paying for costly overtime or, just as bad, having a team sitting around with nothing to do. You staff for the work that is actually coming through the door, not the work that might show up.

Dodging Unnecessary Fees and Preventing Spoilage

One of the biggest money pits in logistics is paying for premium, expedited shipping to fix a problem that was entirely predictable. Good visibility turns this reactive, panicked spending into a calm, proactive strategy.

When you can anticipate delays—whether it's port congestion, a customs hold-up, or bad weather—you have time to make smart adjustments. Instead of shelling out for last-minute air freight, you can simply reroute a shipment or, at the very least, manage your customer's expectations far in advance. The savings here are often enough to pay for the visibility platform itself.

For sensitive or high-value goods, visibility is also your best defence against spoilage and theft.

- Real-Time Monitoring: Think of it like a health monitor for your cargo. IoT sensors can track temperature, humidity, and even shock levels inside a container from start to finish.

- Automated Alerts: If conditions stray outside the safe zone—say, a refrigerated unit falters—the right people get an immediate notification. This allows for intervention before an entire shipment is ruined.

- Quality Assurance: You get a verifiable digital paper trail proving that products were kept under the right conditions. This isn't just good practice; it's essential for compliance in industries like food and pharmaceuticals.

This degree of control is absolutely critical for high-value sectors. When it comes to physical security, a solid strategy includes using the right container seals to prevent theft and tampering. For a deeper dive, check out this a comprehensive guide to seals for containers to lock down this crucial part of your operation.

A Pharmaceutical Company Example

Picture a pharmaceutical firm shipping a batch of life-saving, temperature-sensitive vaccines. In the old world, without real-time visibility, a refrigeration failure mid-transit would go completely unnoticed. The result? A delivery of spoiled, useless product and a loss of millions of pounds—a disaster both financially and for public health.

Now, imagine that same scenario with a modern visibility solution. The second the temperature inside the container creeps above the safe threshold, an automated alert is fired off to the logistics team. They can immediately contact the carrier to get the unit fixed or arrange for the cargo to be moved to a working reefer at the next port. A potential multi-million-pound loss is completely avoided, and a critical delivery is saved.

This proactive power is changing how entire industries manage risk. For example, pharmaceutical companies are increasingly using end-to-end digital visibility to move away from relying on traditional, bulky stockpiles. This shift doesn't just make them more resilient; it directly cuts costs by preventing overstocking and optimises transport routes, which in turn lowers their carbon footprint.

Visibility transforms your supply chain from a sequence of cost centres into a network of strategic opportunities. It's about preventing problems, not just reacting to them, which is the cornerstone of building an efficient and financially sound logistics operation.

Connecting Visibility to a Smaller Carbon Footprint

Better data doesn't just help your balance sheet; it draws a straight line to a greener planet. Using supply chain visibility to reduce cost and emissions isn’t a separate goal—it’s a powerful sustainability tool in its own right. It turns out that a highly efficient, visible supply chain is naturally a more sustainable one.

This connection really clicks when you look at transportation. Without real-time insights, carriers often run inefficiently. They might take longer routes, get stuck in predictable traffic, or travel with half-empty loads. These aren’t just minor operational hiccups; they represent wasted fuel and needless carbon emissions.

Visibility turns this guesswork into precision. By analysing live data, you can consolidate shipments to make sure every truck is full, optimise routes to avoid congestion, and slash wasteful "empty miles"—the costly and carbon-heavy journeys vehicles make with no cargo.

Wasted Goods Equal Wasted Carbon

Beyond the fuel burned during transit, visibility plays a massive role in preventing waste before a product even gets where it's going. Every item that spoils, becomes obsolete, or gets damaged carries a hidden environmental cost. This is its embedded carbon—all the emissions generated during its manufacturing and initial transport.

Think about it: when a shipment of temperature-sensitive food is lost because a refrigeration unit fails, you don't just lose the product. You also waste all the energy, water, and resources used to grow, process, and package it. That entire carbon investment is gone in a flash.

Real-time visibility acts as your safeguard. Temperature sensors can alert you to a problem mid-journey, allowing for immediate action to save the shipment. This direct link between data and waste prevention makes visibility an essential tool for any company serious about its environmental impact.

Accurately Measuring and Reporting Emissions

These days, sustainability is non-negotiable, especially with regulatory pressure mounting. For many businesses, particularly in the EU, measuring and reporting on Scope 3 emissions—those coming from your value chain—is now a legal requirement.

These emissions are notoriously tricky to track because they happen outside your direct control. They include the carbon footprint of your purchased goods, transportation services, and distribution networks. Without solid data, companies are forced to rely on rough estimates, which are no good for compliance and useless for making real improvements.

True supply chain visibility provides the granular, verifiable data needed to move beyond estimates. It captures the actual distances travelled, the specific modes of transport used, and the real-world fuel consumption, giving you an accurate carbon accounting ledger for your entire logistics network.

This level of detail is critical for transparent corporate responsibility and for building a sustainability strategy people can trust. For businesses looking to make a tangible impact, you can explore practical steps to reduce the carbon footprint in your supply chain.

In regions with strong manufacturing ties, like the Czech Republic, the logistics sector is pivotal for hitting these goals. By increasing digital visibility, local manufacturers can use predictive tools and better inventory management to cut down on unnecessary transport runs and optimise their use of different transport networks. You can find more insights on how Czech logistics trends drive efficiency on mordorintelligence.com. This data-driven approach frames sustainability not as an added burden, but as a natural outcome of operational excellence.

Your Roadmap to Implementing a Visibility Strategy

So, how do you go from a supply chain full of blind spots to a clear, data-driven network? It’s a journey, not an overnight switch. This is where we get practical and move from the 'why' to the 'how', laying out a real-world guide to put visibility into practice. Think of this less as installing new software and more as building a culture of making smart, informed decisions.

This roadmap isn't about trying to fix everything at once. The best strategies start small and focused. You prove the value in one area, build momentum, and then expand. It's like building a house—you pour a solid foundation before you even think about putting up the walls.

Pinpoint Your Biggest Blind Spots

First things first: you need to figure out where the lack of visibility is hurting you the most. A quick, structured audit can shine a light on the most critical areas that need attention right now.

Start by asking some honest questions:

- Where are our most frequent and expensive disruptions coming from? Is it always the same supplier running late, or is it unpredictable port congestion?

- Where are we bleeding money on emergency costs? Are you constantly paying a premium for expedited freight just to keep shelves stocked?

- What missing information creates the most guesswork for our team? Is it the lack of reliable arrival times or not knowing exactly what inventory is on the water?

Zero in on the single biggest challenge. This allows you to create a pilot project with a clear, measurable goal. For instance, you could aim to track 100% of inbound shipments from just one major partner. Hitting that target proves the return on investment and makes it much easier to get everyone on board for a wider rollout.

Integrate Data and Choose the Right Tools

Once you have your target, it's time to connect the dots. Real visibility hinges on pulling together data from your entire ecosystem—suppliers, carriers, and partners—into one unified view. That means breaking down those frustrating data silos and picking technologies that make collaboration easy.

This whole process is powered by a set of modern tools that work in concert to create a live, breathing picture of your operations. These technologies are the essential building blocks for any serious supply chain visibility to reduce cost and emissions strategy.

Think of it like this: If your supply chain is a complex machine, data is the oil that keeps it running smoothly. Without information flowing freely between all the moving parts—your suppliers, carriers, and warehouses—the entire system starts to seize up.

Let's look at the key technologies that make this seamless data flow possible. Each one plays a unique role in building a more efficient and sustainable logistics network.

Key Technologies for Supply Chain Visibility

The right tools are what turn visibility from a concept into a reality. The table below breaks down the core technologies that power modern platforms, showing how each one directly helps you cut both operational costs and your carbon footprint.

| Technology | What It Does | How It Cuts Costs and Emissions |

|---|---|---|

| IoT Sensors | Provide real-time data on cargo condition, such as temperature, humidity, and shock. | Prevents costly spoilage of sensitive goods, reducing product waste and the embedded carbon associated with it. |

| GPS & Telematics | Offer precise, real-time location tracking for vehicles, containers, and assets. | Enables route optimisation to cut fuel consumption and allows for proactive rerouting to avoid delays and idle time. |

| Cloud-Based Platforms | Centralise data from all sources (ERP, TMS, carriers) into a single, accessible dashboard. | Eliminates data silos, providing a single source of truth for faster, more informed decision-making across the entire organisation. |

| AI & Machine Learning | Analyse historical and real-time data to predict delays, estimate ETAs, and identify optimisation opportunities. | Moves you from reactive problem-solving to proactive management, identifying potential disruptions before they impact operations. |

As you can see, it’s the combination of these tools that delivers the complete picture. They work together to not only show you where things are but also predict what’s coming next, giving you the power to act before a small hiccup becomes a major crisis.

The Future of Intelligent and Sustainable Logistics

Looking ahead, the next big step in supply chain management isn't just about seeing what's happening right now; it's about accurately predicting what's coming next. This is where AI and machine learning come in, turning today's real-time data into a crystal ball for your logistics network.

We're seeing a fundamental shift in mindset from reactive problem-solving to proactive, intelligent planning. Instead of scrambling when a delay happens, advanced algorithms can see it coming. They analyse everything from weather forecasts and port traffic to historical carrier performance, flagging potential disruptions well before they ever hit your bottom line.

This kind of foresight is built on some seriously sophisticated analytical techniques. The future of smart logistics will lean heavily on methods like predictive modeling in logistics, which essentially uses data to tell the future.

The Rise of the Digital Twin

One of the most exciting concepts making this possible is the supply chain digital twin. Think of it as a complete virtual copy of your entire logistics network—every warehouse, truck, ship, and route. But this isn't just a static map; it's a living model, constantly updated with real-time data from your physical operations.

With a digital twin, you can run an endless number of "what-if" scenarios without any real-world risk. It becomes your operational sandbox.

- What’s the most fuel-efficient route if a major port suddenly closes?

- How would switching from road to rail for a specific lane impact both our costs and emissions?

- Which supplier diversification strategy gives us the best shot at staying resilient during a crisis?

By simulating these possibilities, you can test-drive different strategies to find the most cost-effective and low-emission pathways before you ever commit a single euro. This technology opens the door to continuous, data-driven fine-tuning of your entire operation.

Supply chain visibility is no longer a 'nice-to-have' feature. It is the essential foundation for any modern, resilient, and responsible business aiming to thrive in a competitive and climate-conscious global market.

At the end of the day, using supply chain visibility to reduce cost and emissions is about building a smarter, more agile, and genuinely sustainable future. This is the heart of effective environmental governance, a topic you can dive deeper into by checking out the top carbon accounting platforms for sustainable success.

Got Questions? We’ve Got Answers

Diving into supply chain visibility can feel like a big step, and it's natural to have questions. Let's tackle some of the most common ones that come up when businesses start thinking about how to see their supply chain more clearly to cut costs and emissions.

What's the Best Way to Get Started with Supply Chain Visibility?

Start small. Seriously. The best thing you can do is pick your single biggest headache and focus on fixing that first.

Maybe it's the constant delays from one specific supplier that throws your whole production schedule into chaos. Or perhaps you're bleeding money on last-minute expedited freight. Whatever it is, zero in on that one issue.

By running a small, targeted project—like tracking every shipment from that one troublesome supplier—you can solve a real problem and show a clear return on investment. This success makes it much easier to get everyone on board when you're ready to expand the project across your entire network.

How Does This Actually Help with Scope 3 Emissions Reporting?

Scope 3 emissions are tricky because they happen outside your own four walls, deep within your value chain. This is where visibility tools really shine. They give you the real-world, granular data you need to stop guessing and start calculating accurately.

Instead of relying on vague industry averages, you can track the exact routes your shipments took, the type of truck that was used, and the actual weight of the cargo. This level of detail allows you to calculate your transport emissions with precision. That kind of verifiable data isn't just nice to have; it's becoming essential for credible ESG reports and meeting new EU regulations.

Think of it this way: visibility turns your emissions reporting from guesswork into an exact science. You get the hard data needed to back up your green claims and build real trust with customers and investors.

Aren't These Kinds of Solutions Just for Giant Global Companies?

That used to be true, but not anymore. While the big players were the first to jump in, modern cloud-based software has made visibility technology affordable and accessible for businesses of all sizes.

Many platforms now offer a pick-and-choose model, which is perfect for smaller companies. You can start with a basic tracking plan for just one critical shipping route to prove it works for you. As your business grows, you can add more features and expand your coverage. The solution grows with you, so you don't need a massive upfront investment to get started.

How Do I Convince My Suppliers and Carriers to Share Their Data?

This is a big concern for many, but it's less of a hurdle than you might think. The trick is to show them what's in it for them. This isn't about you demanding their data; it's about creating a more efficient system where everyone wins.

- For your carriers: They can slash expensive wait times at your warehouses and find better routes in real time. That means they save fuel and get more out of their trucks.

- For your suppliers: When they can see your inventory levels and production needs, they can plan their own work far more effectively, which cuts their own costs.

The best approach is to start with one or two key partners you have a good relationship with. Show them the benefits firsthand. Once you prove that better data leads to smoother operations and lower costs for everyone involved, you'll find that other partners will be eager to get on board. A rising tide of good data really does lift all boats.

Ready to make visibility your secret weapon? Carbonpunk’s AI-powered platform helps you see, understand, and reduce your supply chain emissions with incredible accuracy. It’s time to stop estimating and start optimising. Find out how Carbonpunk can change your logistics game.