A Guide to Warehouse Layout Optimization

Karel Maly

August 13, 2025

Forget tidying up shelves. Real warehouse layout optimisation is about fundamentally rethinking how your goods, people, and equipment move and interact. It’s a deep, strategic dive into designing your space to turn it from a simple cost centre into a genuine competitive edge. This isn't about minor tweaks; it's a guide to a complete warehouse transformation.

Your Warehouse Is an Untapped Strategic Asset

So many businesses see their warehouse as just a box—a static, four-walled space for holding inventory until it's needed. Honestly, that perspective leaves a massive opportunity on the table. A truly optimised warehouse is a dynamic, living system built for peak performance. The layout directly dictates your operational costs, how quickly you can fulfil orders, and even how safe your team is.

Thinking strategically about your layout means you're not just looking at shelves. You're mapping the entire journey of a product, from the moment it hits the receiving dock to the second it’s loaded for its final delivery. The goal is simple but powerful: slash travel time, cut out unnecessary handling, and make every single square metre count.

The Real-World Impact of Intelligent Design

When you start treating your warehouse layout as a critical business function, the benefits you see go way beyond a tidy floor. The improvements are concrete, measurable, and hit your bottom line directly.

- Significant Cost Reductions: Shorter travel paths for your pickers and forklifts mean lower labour costs and less fuel or energy burned. It's that straightforward.

- Faster Fulfilment Speeds: A logical flow from receiving to picking to shipping gets orders out the door faster. This boosts customer happiness and can even let you offer later order cut-off times.

- Increased Storage Capacity: Smart design isn't just about floor space; it's about volume. Optimising aisle widths and making better use of vertical space can dramatically increase your storage capacity without the massive cost of an extension. A good rule of thumb is that a warehouse is effectively "full" at 85% occupancy—anything higher creates gridlock and kills efficiency.

- A Safer Work Environment: A well-planned layout naturally reduces traffic jams. It minimises the risk of close calls or collisions between people and machinery, creating clearer, safer pathways for everyone.

One of the most common mistakes I see is businesses waiting until they're bursting at the seams to think about their layout. Proactive optimisation prevents these bottlenecks from ever forming, ensuring your operations can scale smoothly as you grow.

The Pillars of a Successful Warehouse Transformation

A great redesign isn't based on gut feelings or copying a "standard" layout you saw somewhere else. It has to be built on a solid foundation of data and a deep understanding of your specific operational reality. The whole process really boils down to three key pillars: data analysis, process mapping, and intelligent design.

A fantastic case in point comes from a project with DHL Czech Republic, where they optimised the layout for the footwear brand Humanic. They didn't just move things around; they analysed inventory data and tracked picker movements to reorganise stock based on how fast it sold. This data-driven approach resulted in a 22% reduction in average walking distances and an 8% increase in picking productivity. You can read more about how this specific layout redesign boosted efficiency.

It's proof that even seemingly small, data-backed changes can deliver huge returns, turning your warehouse into a high-performance engine for your business.

Mapping Your Current State to Uncover Inefficiencies

You can't fix what you can't see. Before you start dreaming up a new, high-performance layout, you've got to get a brutally honest picture of how your warehouse operates right now. A simple floor plan won’t cut it. Real optimisation starts with understanding how people and products actually move through your space—not just how they’re supposed to. This initial mapping is the bedrock for any meaningful change.

The entire point here is to stop guessing. We need to gather cold, hard data on the daily journey of your team, your equipment, and your inventory. This is how you find the hidden friction points: the congested aisles, the redundant travel paths, and the wasted movements that quietly bleed time and money from your operation every single day.

Going Beyond the Blueprint

Your first real task is to create a visual map of your operational flows. For this, I always fall back on a classic, incredibly effective tool: the spaghetti diagram. Just like it sounds, you trace the physical paths your workers and equipment take on a scaled drawing of your warehouse floor. The resulting web of lines shows you exactly where the chaos is.

And you don't need fancy software to get started. Honestly, a stopwatch, a clipboard, and a sharp eye are all you need.

- Shadow a Picker: Follow a team member through several order-picking cycles. Draw their exact path from the moment they get a pick list to the second they drop off the completed order.

- Trace a Forklift: Map out a forklift's typical route—from the receiving dock, to put-away locations, through replenishment tasks, and over to the shipping area.

- Follow an Item: Pick a single SKU and trace its entire journey from the moment it arrives until it's sitting in its final storage spot.

After just a few of these cycles, the "spaghetti" starts to take shape. You'll immediately see dense clusters of lines that scream "bottleneck!" and long, winding paths that double back on themselves, which is a dead giveaway for inefficient travel and a poor slotting strategy.

Gathering Actionable Data

Visual maps are great for a quick diagnosis, but you need numbers to back them up. Your Warehouse Management System (WMS) is an absolute goldmine for this. Dig into your WMS reports to find hard data that adds weight to what you’re seeing on the floor. Look for travel times between zones, pick rates per employee, and how often different SKUs are accessed.

Now, combine that WMS data with your own on-the-floor observations. For example, time how long it actually takes a picker to walk from your fast-moving goods area to the packing station. If your WMS data then confirms that your top-selling products are stored in the back corner, furthest from shipping, you’ve just nailed down a massive inefficiency.

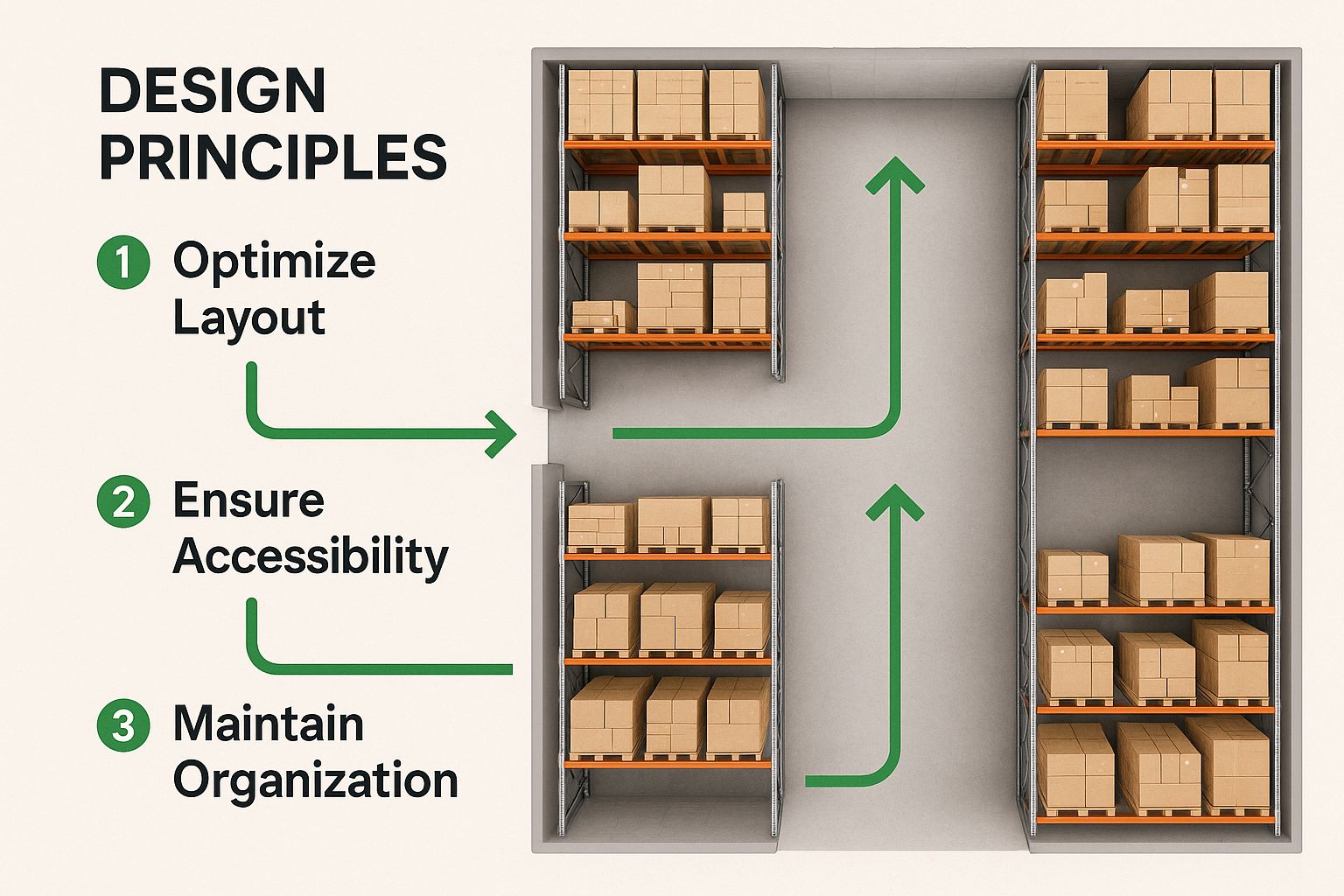

This infographic highlights some of the core design principles that naturally come out of this kind of data analysis.

As the visual shows, everything comes down to strategic placement based on product flow and velocity. That’s the heart of a smart warehouse design.

Finding these problems is the first critical step. It lets you go from a vague feeling of "we could be faster" to a specific, provable problem like, "Our current layout forces pickers to walk an extra 500 metres per order just to get our top 20 SKUs."

This data-first approach is non-negotiable. It gives you a clear baseline to measure the success of any changes you make later. When you can walk into a meeting and show exactly where and how much time is being wasted, you build a rock-solid case for investing in a redesign. It takes all the guesswork out of the equation and makes sure you’re tackling the problems that will give you the biggest return.

Designing a High-Performance Layout with Data

Now that you have a solid grasp of your current inefficiencies, it’s time to shift from diagnosis to design. This is the exciting part, where you get to architect a new layout. Forget guesswork; we’re building this based on the cold, hard data you've just collected. A truly high-performance warehouse isn't just four walls and some racks—it's an asset intentionally built around your unique product velocity and operational goals.

Moving past a simple floor plan means getting to grips with how different design choices will affect your day-to-day. When you let the data lead, every decision, from aisle width to pallet placement, has a clear purpose. You're directly targeting the bottlenecks you've already identified.

Applying ABC Analysis for Smart Slotting

The cornerstone of any data-driven layout is a smart slotting strategy. And from my experience, the most practical way to build one is through ABC analysis. This technique isn't about categorising inventory by size or supplier; it’s all about how fast things move off the shelf.

It’s a beautifully simple concept that pays huge dividends:

- 'A' Items: These are your rock stars. They represent the top 20% of your products but drive a massive 80% of your sales volume. They need to be front and centre, no exceptions.

- 'B' Items: This is your solid middle group, making up about 30% of your SKUs and contributing roughly 15% of your movements. They're important, but not in constant demand.

- 'C' Items: These are the slow-burners. They fill out the bottom 50% of your SKU list but only account for about 5% of your sales.

Once you’ve sorted your inventory this way, the layout practically designs itself. Your 'A' items belong in the prime real estate—right by the packing and shipping stations to slash picker travel time. Your 'C' items? They can be placed in less accessible areas, like higher up on racks or further back in the warehouse, because you simply don't need to get to them as often.

This single strategy is a direct attack on the wasted motion we saw in those spaghetti diagrams. It ensures your team spends their valuable time picking and packing, not wandering the aisles.

A classic mistake I see is warehouses organised by product category or supplier. It seems logical, but it completely ignores how quickly products sell. This leads to frustrating scenarios where a best-selling item is buried in a back corner, just because it sits next to similar but less popular products.

For a great example of this principle in action, just look at how dm drogerie markt, a major drugstore chain in the Czech Republic, tackled their new warehouse. They performed an incredibly detailed data analysis on product turnover, weight, and handling requirements. This deep dive allowed them to strategically place every single pallet, aligning the entire layout with their operational needs and scoring some serious reductions in labour costs.

Choosing the Right Flow for Your Operation

With your slotting strategy nailed down, the next big decision is the overall flow of materials. Generally, you’ll be choosing between a U-shaped or an I-shaped (also called through-flow) layout. Neither is universally better; the right choice is completely dependent on your specific operation.

| Layout Type | Description | Best For |

|---|---|---|

| U-Shaped Flow | Receiving and shipping docks are next to each other on the same side of the building. Goods move in a 'U' from receiving, to storage, to picking, and back to shipping. | Smaller operations or facilities where dock space is limited. It allows for shared staffing and equipment between receiving and shipping, improving resource utilisation. |

| I-Shaped Flow | Receiving is at one end of the warehouse, and shipping is at the opposite end. Inventory moves in a straight line through the facility. | Larger, high-volume operations where cross-docking is common. This layout keeps receiving and shipping activities completely separate, preventing congestion. |

A U-shaped flow is fantastic for consolidating your resources, while an I-shaped flow is unbeatable for preventing traffic jams in high-speed environments. Let your data on congestion and throughput be your guide here. As you sketch out your new layout, it’s worth exploring different strategies for designing storage facilities for maximum efficiency to get more ideas.

Optimising Every Square Metre

Finally, it’s time to get granular. The goal is to maximise every bit of horizontal and vertical space while carving out dedicated zones for specific tasks.

- Calculate Aisle Widths: This is always a balancing act. Wider aisles are great for bigger equipment and two-way traffic, but they eat up valuable floor space. Narrowing your aisles can boost storage capacity by 15-20%, but you might need to invest in specialised forklifts.

- Go Vertical: Don't forget to look up! Using taller racking systems is often the most cost-effective way to increase capacity without expanding your footprint. Just be sure to check your building's clear height and confirm your fire suppression systems are up to the task.

- Create Dedicated Zones: Bring order to the chaos by setting up distinct, clearly marked areas for receiving, quality control, packing, value-added services (like kitting or bundling), and returns. This stops processes from bleeding into one another and keeps your main fulfilment path clear.

Thinking about carbon management at this stage can also unlock some powerful, compounding benefits. For instance, a layout that minimises forklift travel doesn't just save on labour and fuel—it also directly lowers your Scope 1 emissions. And when you connect your efficient new layout to a https://www.carbonpunk.ai/en/blog/modern-logistics-route-planning-guide, you ensure that the gains you make inside the warehouse are amplified by smarter, lower-emission transport on the road.

Validating and Implementing Your New Layout

A design on paper is just a theory. Before you commit to the serious cost and operational disruption of a physical rearrangement, you have to put your proposed layout through its paces. This is the crucial step that turns a well-researched guess into a predictable, high-performance model, making sure your investment will actually deliver the returns you expect.

The goal here is simple: test your new design against the same real-world situations you mapped out in your initial analysis. How does it handle your highest-volume picking paths? What does the flow look like during a peak receiving period? This is your chance to find and fix any remaining friction points before they become expensive, concrete-and-steel problems.

Simulating the New Flow

Simulation is where your data-driven design really comes to life. It lets you calculate projected improvements with a surprising degree of accuracy, giving you the hard numbers needed to get that final sign-off from management. And you don't always need complex, expensive software to get meaningful results.

- Tabletop Models: For simpler operations, a physical model can be incredibly powerful. Grab a scaled floor plan and use small blocks or tokens to represent forklifts, pickers, and pallets. Then, walk through your most common workflows—order picking, put-away, replenishment—and time them. It’s a low-tech approach, but it’s fantastic for visualising traffic flow and getting direct, hands-on feedback from your floor team.

- Digital Twinning: For more complex facilities, digital twinning software is the way to go. It creates a virtual replica of your warehouse where you can feed it your WMS data and run thousands of simulations. You can test how the layout holds up under different demand scenarios, accurately forecasting everything from picker travel distances to potential bottlenecks.

For any major redesign, especially one involving new racking and conveyor systems, it's vital to identify and resolve interferences before installation begins. Using techniques like clash detection and coordination can save you from incredibly costly errors down the line.

The image below, from a study on warehouse layout optimisation, shows exactly what we're talking about by comparing travel paths.

It's clear just from a glance how a redesigned layout (Map 2) creates much more direct and efficient routes compared to the tangled original.

Key Takeaway: Validation isn't about proving your design is perfect. It's about finding its weaknesses in a low-risk environment. Every problem you solve in a simulation is a major headache you've avoided on the warehouse floor.

A fascinating study from the Czech supply chain sector really drives this home. By comparing a baseline layout with two optimised versions, researchers found that the best redesign cut travel distances by about 31%. This wasn't just about saving money on logistics; it also improved worker well-being by reducing their physical strain. You can discover more about these findings and their impact on operational efficiency.

Creating a Phased Implementation Plan

Once your layout is validated and refined, it's time to make it happen. Rushing this is a recipe for absolute chaos. What you need is a carefully phased plan that keeps disruption to a minimum while your day-to-day operations continue to run.

Think of the implementation like any other major project—it needs clear communication, defined timelines, and dedicated resources.

First, communicate clearly and early. Get your entire team in the loop. Explain the "why" behind the changes, showing them the simulation results and how the new layout will make their jobs easier and safer. Listen to their concerns and make them part of the solution.

Next, manage the inventory relocation strategically. Don't try to move everything at once. Plan the move in sections, ideally during off-peak hours or over a weekend. I always suggest starting with your 'C' items (the slowest movers) to get the process down before you touch your critical, high-velocity 'A' items.

Finally, train everyone on the new processes. A new layout almost always means new standard operating procedures (SOPs). Run thorough training sessions for all staff, covering new picking paths, storage rules, and any updated safety protocols. Just as important, allow for a ramp-up period as they get used to the new flow.

By breaking the implementation into manageable pieces, you maintain business continuity and slash the risk of costly mistakes. This structured approach, combined with better visibility into your processes, ensures the benefits you designed on paper are fully realised on the warehouse floor. To learn more about how operational transparency can support projects like this, you might be interested in mastering supply chain visibility for your business.

So, you’ve launched your new warehouse layout. That’s a massive achievement, but don’t crack open the champagne just yet. This isn’t the finish line; it’s the starting block for the next race. The single biggest mistake I see companies make is treating warehouse layout optimisation as a one-off task. To truly get a return on your hard work, you need to shift your thinking from a "project" to a "process."

A high-performing warehouse is a living, breathing thing. It needs constant attention. Market tastes change, product popularity waxes and wanes, and inefficiencies have a sneaky way of creeping back in when you’re not looking. Keeping your warehouse at peak performance means staying vigilant, watching the data, and building a team culture where everyone feels they can point out what’s not working.

Keep Your Eyes on the Right KPIs

As the old saying goes, you can't manage what you don't measure. After your redesign, your Key Performance Indicators (KPIs) are your new best friend. They’re the dashboard telling you exactly how your layout is holding up and flashing warning lights when problems start to emerge.

Don’t get lost in a sea of data. Focus on a few critical metrics that tie directly back to your original optimisation goals:

- Order Cycle Time: This is the big one—the total time from a customer's click to the box leaving your dock. If this number starts to creep up, it's a huge red flag that friction is finding its way back into your workflow.

- Picking Accuracy: Are your error rates still impressively low? If you see a spike in mistakes, it could mean the new layout is causing confusion, or maybe your slotting needs another look.

- Pick Rate: How many items or orders can your team pick per hour? This directly measures their productivity and tells you if the layout is actually making their job easier.

- Inventory Turnover: This shows you how fast you're selling through your stock. Keeping an eye on it helps you catch changes in product velocity before they become a problem.

Set clear baselines for these KPIs immediately after the go-live. A steady decline in performance is your signal to get on the floor and figure out why before a small snag turns into a system-wide bottleneck.

Cultivate a Culture of Continuous Improvement

Your most valuable asset isn't a new forklift; it's the people working on the warehouse floor. Your pickers, receivers, and drivers are the ones who live and breathe this layout every single day. They’re the first to feel when a process is awkward or when a top-selling product is buried at the back of a rack.

You have to empower them to be your eyes and ears. Create a simple, no-fuss way for them to share ideas or flag problems. This could be a quick weekly huddle, a suggestion box, or a dedicated channel on your internal messaging app. When an operator tells you that Aisle 7 is a traffic jam at 2 PM every day, that's not a complaint—it's gold-standard, actionable data.

When you build this culture, your team stops being just workers and starts becoming owners of the warehouse's success. They won't just help you maintain performance; they'll often spot opportunities for tweaks you would have completely missed.

Revisit Your Slotting Strategy Regularly

Remember that ABC analysis you did during the design phase? It has a shelf life. Product demand is never static; today’s superstar seller could be gathering dust next quarter. A "set it and forget it" slotting strategy is a surefire way to watch your hard-won efficiency gains evaporate.

Make it a habit to review and re-run your ABC analysis. For most businesses, doing this quarterly is a good rhythm. If you're in a fast-paced industry like fashion or consumer electronics, you might even want to do it monthly. When the data shows that a former 'B' item is now flying off the shelves like an 'A' item, it's time to physically move it to a prime, easy-to-access picking spot.

This proactive reslotting does more than just keep your layout aligned with sales reality; it also makes your operations more sustainable. Every metre of forklift travel you eliminate saves time, fuel, and money—and it cuts down your operational emissions. To see how these small wins contribute to a bigger picture, our guide on building a decarbonisation platform can provide some valuable context. Ultimately, maintaining an optimised layout is one of the most practical things you can do to build a more efficient and sustainable supply chain.

Frequently Asked Questions

It's completely normal to have a few questions, even with a solid plan in hand. Changing your warehouse layout is a major project, so it's smart to think through all the angles before you dive in. We’ve pulled together some of the most common questions we get from managers on the ground to give you some direct, practical answers.

These aren't textbook theories; they're insights drawn from years spent on the warehouse floor, seeing what works—and just as importantly, what doesn't.

How Often Should I Review My Warehouse Layout?

One of the biggest misconceptions is that a warehouse layout is a "set it and forget it" job. The truth is, your layout should be a living part of your operation, one that evolves as your business does. While there isn't a single magic number, a good rule of thumb is to conduct a full-scale review every 3-5 years.

That said, some events should trigger an immediate rethink, no matter where you are in that cycle. Watch for these signals:

- Your product mix has shifted: If your top-selling items have changed, your entire slotting strategy is likely out of date.

- You've brought in new equipment: Introducing new MHE, like narrow-aisle forklifts or AMRs, often demands different aisle widths and travel paths to be effective.

- Your KPIs are consistently slipping: If metrics like order cycle time or pick rates are getting worse month after month, your layout is probably creating friction.

- Congestion is the new normal: When you start seeing daily traffic jams in aisles or around the docks, it's a clear sign it's time to act.

Keeping a regular eye on things prevents small inefficiencies from snowballing into massive operational headaches.

What Are the Most Common Mistakes to Avoid?

It's surprisingly easy to fall into a few common traps during a redesign, which can completely undermine all your hard work. Knowing what they are is the first step to dodging them.

The biggest error I see is designing in a vacuum. A layout might look perfect on a computer screen, but it can be totally impractical for the team on the floor. You absolutely have to involve your pickers, forklift drivers, and receiving staff in the process. Their real-world feedback is gold.

Another frequent oversight is ignoring vertical space. So many operations get hyper-focused on the floor plan that they forget to look up. Going vertical with taller racking is often the most cost-effective way to boost storage capacity without a costly building expansion.

The most subtle yet damaging mistake? Prioritising tidy product categories over picking speed. It feels logical to group all similar items together. But if your best-seller is stuck at the back of the warehouse just to be with its "family," you're deliberately building inefficiency into your workflow.

Do These Principles Apply to Smaller Warehouses?

Absolutely. In fact, you could argue they're even more critical for smaller operations.

When you have less space to play with, every single square metre has to pull its weight. In a massive distribution centre, a few metres of wasted aisle space might not even be noticed. In a smaller facility, that same wasted space could represent a huge chunk of your total storage area.

Small warehouses can see huge gains from:

- Smart Slotting: Placing your fastest-moving products closest to the packing bench can slash travel time, which makes a massive difference when your team wears multiple hats.

- U-Shaped Flow: This layout is often perfect for smaller footprints because it allows receiving and shipping to share the same docks and staff, making the most of your resources.

- Getting Creative: I've seen smaller warehouses do brilliant things like adding shelving over doorways or using mobile racking to create flexible storage zones on the fly.

The fundamental goal of warehouse layout optimisation—to cut travel, eliminate waste, and increase throughput—is the same, no matter the size of your building.

Transforming your warehouse layout is a powerful step towards operational excellence. The next is managing its environmental impact with the same level of precision. Carbonpunk provides the AI-driven platform to measure, manage, and reduce your supply chain's carbon footprint, turning your sustainability goals into measurable achievements. Discover how you can decarbonise your logistics at Carbonpunk.