Modern Logistics Route Planning Guide

Karel Maly

July 18, 2025

When we talk about logistics route planning today, we're talking about something far more sophisticated than just finding the quickest way from A to B. It's the strategic art of figuring out the absolute best sequence of stops for an entire fleet of vehicles.

This process juggles a whole host of real-world variables—think live traffic, tight delivery windows, vehicle load limits, and even driver break times—all to cut down on costs and keep customers happy.

The Evolution of Logistics Route Planning

Think of a seasoned chess grandmaster who can see the entire board, plotting out moves ten steps ahead. That's the essence of modern route planning. We've moved past the days of sticking pins in a physical map. Now, it's a strategic discipline that orchestrates a complex symphony of data to hit peak efficiency.

What used to be a mind-numbing, time-consuming puzzle for planners has become one of the sharpest tools in a company's arsenal. Where people once spent hours wrestling with spreadsheets and maps, powerful software now does the heavy lifting, sifting through endless possibilities in seconds. This lets businesses go from just getting the job done to getting it done flawlessly.

The goal has always been simple: get goods from origin to destination at the lowest possible cost, while keeping every promise made to the customer. The real challenge, however, is pulling this off flawlessly across hundreds, or even thousands, of daily deliveries.

This shift couldn't be more critical, especially in a booming market. Take the industrial and logistics sector in the Czech Republic, which saw robust activity with around 155,900 square metres of new industrial space completed in Q1 2024 alone. This kind of growth puts immense pressure on logistics operations, making sophisticated planning an absolute necessity. You can dive deeper into the Czech Republic's industrial and logistics market figures from CBRE to see the full picture.

From Manual Guesswork to Automated Precision

Let's quickly compare the old way of doing things with the new.

A quick comparison showcases the key differences between traditional manual planning and modern automated systems.

Manual Vs. Automated Route Planning At A Glance

| Aspect | Manual Planning | Automated Planning |

|---|---|---|

| Tools | Spreadsheets, physical maps, gut instinct | AI-powered software, GPS, live data feeds |

| Adaptability | Slow to react to changes (e.g., traffic) | Instantly adapts to real-time events |

| Efficiency | Often results in suboptimal, costly routes | Finds the most efficient path in seconds |

| Scale | Limited to a small number of vehicles/stops | Can manage hundreds of vehicles and thousands of stops |

| Data Use | Relies on static, historical information | Processes dynamic, live data streams |

The difference is night and day. Manual planning is fundamentally reactive; it’s constrained by what a single person can juggle in their head, often leading to routes that burn unnecessary fuel and waste precious time.

Automated systems, on the other hand, are proactive. They use intelligent algorithms to weigh thousands of variables at once. This means they can optimise for everything simultaneously, from vehicle capacity and driver shifts to the carbon impact of shipping and logistics.

This shift towards automation does more than just make things run smoother. It directly fattens the bottom line and strengthens customer relationships. When deliveries are consistently on-time and reliable, you build trust and loyalty. Suddenly, logistics is no longer just a cost centre—it becomes a powerful way to stand out from the competition. In today's market, mastering this isn't just an option; it's essential for survival and growth.

Why Optimised Routes Are a Competitive Advantage

Think of effective route planning not just as a way to tidy up your daily operations, but as a core business strategy that gives you a serious competitive edge. Of course, the most obvious win is saving money. But the real magic happens when those savings ripple out across your entire business, turning your logistics department from a necessary expense into a powerful engine for growth.

The first thing you'll notice is the impact on your bottom line. Simply finding the most efficient paths for your vehicles can dramatically cut fuel consumption—often one of the biggest and most unpredictable costs for any fleet. Fewer kilometres on the road also means less wear and tear, which translates to lower maintenance bills and a longer life for your vehicles.

But the benefits don't stop at the bank. Think about your people. Well-planned routes lead to balanced, realistic schedules for your drivers. This isn't just about making their day-to-day work less stressful; it boosts morale, reduces burnout, and ultimately helps you keep good drivers on your team. In an industry constantly battling driver shortages, that’s a huge advantage.

Building Reliability and Customer Loyalty

At the end of the day, though, the biggest win is what this all means for your customers. Optimised routes are predictable routes. And predictability is the absolute bedrock of reliability. When you can consistently hit—or even beat—your promised delivery times, you build a massive amount of trust.

This reliability becomes your brand's calling card. In a crowded marketplace, a customer who knows their package will show up exactly when you said it would is a customer who will come back again and again. For any business serious about getting ahead, mastering routing optimisation strategies is the secret to building that kind of loyalty.

Optimised logistics isn't just about speed. It’s about being smarter. It means making fewer promises but keeping every single one of them, which is the cornerstone of great customer service and a rock-solid brand reputation.

This kind of efficiency is especially vital in a growing economy. Here in the Czech Republic, the freight and logistics market is expanding, thanks to our central European position and a booming e-commerce scene that requires incredibly efficient delivery networks. As the market grows, the companies that have truly mastered logistics route planning will be the ones who snag the new opportunities and cement their place at the top.

The Snowball Effect of Optimisation

The great thing is that these advantages don't just exist on their own. They build on each other, creating a powerful cycle of continuous improvement.

- Cost Savings Fuel Growth: The money you save on fuel and maintenance isn't just profit. It’s capital you can reinvest into better technology, new vehicles, or expanding your services.

- Happier Drivers, Happier Customers: A stable, professional team of drivers delivers a consistently better service. That positive experience is felt directly by your customers.

- Reliability Drives Reputation: A strong reputation for being on time, every time, becomes one of your best marketing tools. It attracts new clients and solidifies your status as a leader in the field.

When you connect all these dots, it becomes crystal clear. Superior logistics route planning isn't just a back-office task. It’s a strategic necessity that has a direct line to your profitability, your team's stability, and your customers' loyalty.

Navigating Common Route Optimisation Hurdles

While the benefits are crystal clear, the journey toward perfect logistics route planning is almost never a straight line. Ask any dispatcher—even the most carefully constructed plan can be completely derailed by the messy reality of the outside world. Making the leap from manual methods to truly optimised operations means facing a few common, but significant, hurdles.

One of the biggest headaches is simply keeping up with dynamic changes. The real world doesn't stick to a neat schedule. A last-minute order pops up, a customer suddenly cancels, or a surprise road closure brings a perfectly good route to a screeching halt. Manual systems are just too stiff to pivot, leading to a flurry of panicked phone calls and inefficient detours that burn both time and money.

Then there's the challenge of juggling wildly different customer demands. Today’s customers expect pinpoint accuracy, whether it's a tight one- or two-hour delivery window or specific notes on how to handle their parcel. Trying to meet these varied expectations without a solid system can feel like trying to solve an impossible puzzle, putting your service quality and reputation on the line.

The Problem of Scale and Integration

As your business expands, the manual planning that worked for a small fleet starts to buckle under the strain. What was manageable with three vehicles becomes pure chaos with ten. This scalability problem is precisely why so many businesses start looking for automated solutions; at a certain point, a human planner just can't compute all the variables anymore.

The breaking point often arrives when the time spent planning routes starts to exceed the time saved on the road. This is the moment when reactive problem-solving must give way to proactive, technology-driven optimisation.

On top of that, bringing in new software can create its own set of technical challenges. A route planning tool can't operate in a silo. It needs to talk to all the other systems you already rely on.

Key integration points often include:

- ERP Systems: Making sure order and stock data flows smoothly into the routing software.

- WMS (Warehouse Management Systems): Syncing picking and packing status with vehicle loading and dispatch times.

- CRM (Customer Relationship Management): Automatically pulling customer addresses and delivery preferences to eliminate manual data entry errors.

Shoddy integration creates data islands and forces manual workarounds, completely defeating the purpose of adopting new tech. Overcoming these hurdles is essential, not just for smoother day-to-day operations but also for unlocking bigger wins. In fact, once your routes are properly sorted, you can learn how to reduce supply chain carbon emissions with expert strategies. By tackling these challenges head-on, you clear the path for technology to deliver the robust solutions modern logistics demands.

How AI Transforms Modern Route Planning

Let's be clear: artificial intelligence isn't just another tool in the logistics toolbox. It's the master architect redesigning the entire field of logistics route planning. Imagine having an expert local guide who not only knows every shortcut in the city but can also predict traffic jams hours before they even start. That’s what AI brings to the table, crunching thousands of variables at once—a task that's simply impossible for a human.

Where a human planner might see a straightforward list of stops, an AI sees a complex, multi-layered puzzle. It’s simultaneously analysing live traffic feeds, weather forecasts, vehicle capacities, driver schedules, and precise delivery windows. This allows it to graduate from merely finding the shortest route to identifying the truly optimal one.

Predictive Power and Dynamic Adaptation

One of the most powerful things AI brings to logistics is predictive analytics. By learning from historical traffic data, past delivery times, and even seasonal demand shifts, AI models can forecast future conditions with impressive accuracy. This means your route plan for tomorrow is already optimised for the traffic you’re likely to face, not just the traffic on the road right now.

But what happens when things go wrong? A sudden accident blocks a main road, or an urgent, high-priority order gets added to the schedule midday. This is where AI's ability to adapt on the fly really shines.

An AI-powered system doesn't just hand you a static plan and wish you luck. It acts as a live co-pilot for your entire fleet, constantly monitoring conditions and automatically adjusting routes in real time to sidestep disruptions and keep everything running smoothly.

This constant, real-time adjustment ensures that even on the most chaotic days, your fleet operates at peak efficiency, saving fuel and preventing late deliveries. For a deeper look into these advancements, you can find great insights on how AI transforms drone flights, which highlights how these same optimisation principles apply across the entire logistics spectrum.

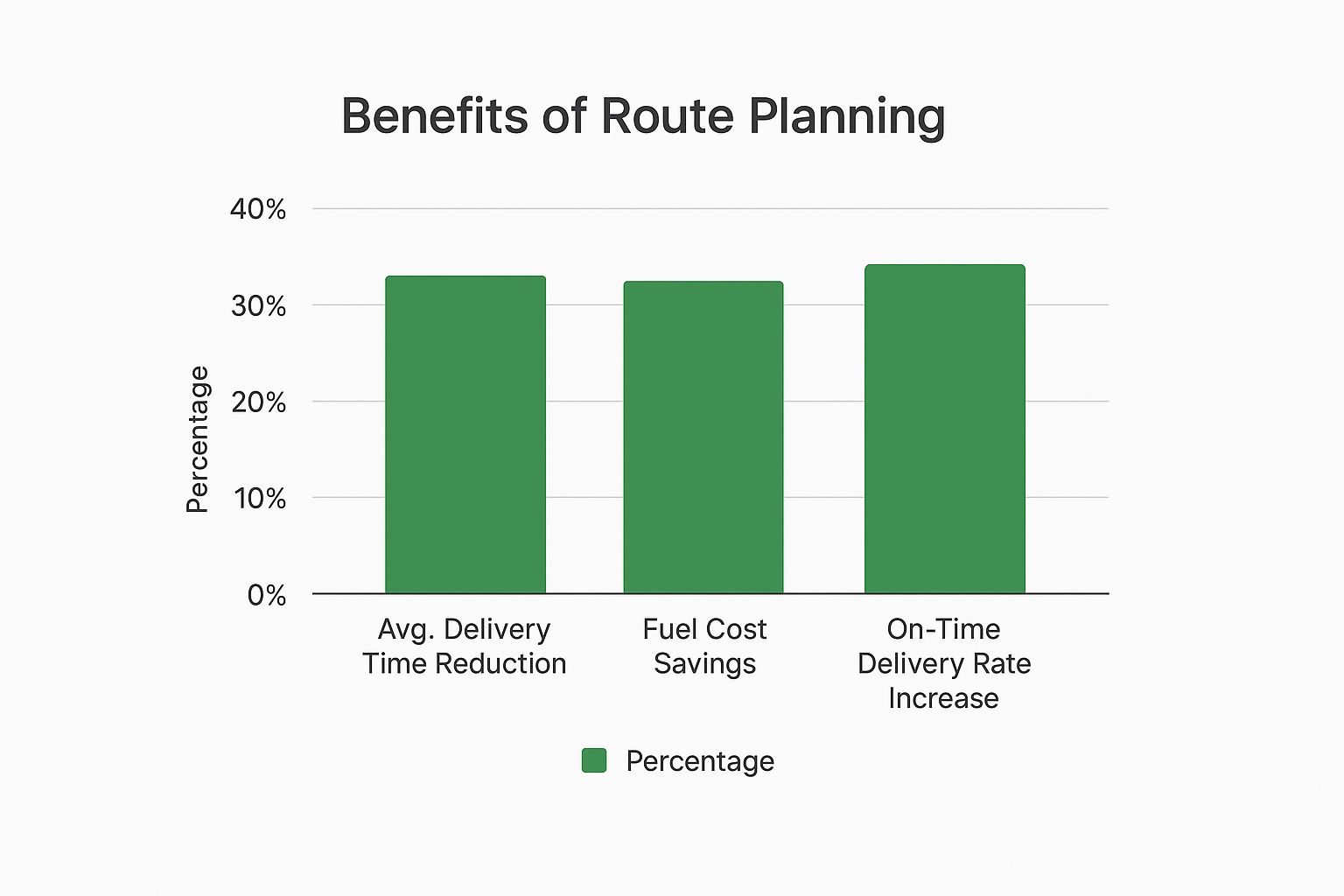

This chart shows the direct impact these AI-driven efficiencies can have on the numbers that matter most.

The data speaks for itself. Putting intelligent route planning into practice leads to significant, measurable improvements across the board, from getting packages to customers faster to making a real dent in operational costs.

Key AI Capabilities in Route Planning

To really grasp how this works, it helps to break down the specific features AI brings to route planning and the concrete benefits they deliver.

| AI Capability | What It Does | Business Benefit |

|---|---|---|

| Predictive Analytics | Analyses historical data to forecast traffic, weather, and demand patterns. | Creates proactive, more reliable routes; reduces delays from predictable events. |

| Dynamic Rerouting | Monitors real-time conditions and automatically adjusts routes to avoid unexpected disruptions. | Improves on-time delivery rates; increases fleet agility and resilience. |

| Multi-Objective Optimisation | Balances competing goals like cost, speed, and sustainability based on business priorities. | Allows for strategic planning that aligns with company goals, not just speed. |

| Load & Capacity Planning | Calculates optimal vehicle loads and stop sequences based on item size, weight, and delivery windows. | Maximises vehicle utilisation; reduces the number of trips and associated fuel costs. |

These capabilities work together, turning a sea of complex data into a clear, actionable strategy for your fleet.

Optimising for More Than Just Speed

Today’s AI does so much more than basic time and distance calculations. It allows a business to optimise for several, often competing, goals at the same time. This is where a platform like Carbonpunk truly proves its worth, translating complex variables into smart, money-saving decisions.

AI algorithms can be fine-tuned to prioritise what matters most to your operation:

- Cost Reduction: The system can be set to focus purely on minimising fuel consumption and driver hours, which has an immediate impact on your bottom line.

- Customer Satisfaction: It can prioritise hitting tight delivery windows above all else, which is key for boosting service reliability and keeping customers happy.

- Sustainability: The AI can specifically design routes that minimise CO₂ emissions, helping your company achieve its environmental targets. In fact, studies show optimised routes can reduce fuel costs by up to 40%, which is directly tied to a smaller carbon footprint.

By turning these complex trade-offs into clear, optimised plans, AI takes the guesswork out of logistics route planning. It gives dispatchers the power to make smarter, data-backed decisions that save money, improve service, and support sustainability, ultimately turning logistics from a cost centre into a real strategic advantage.

Implementing Your Route Planning System

Bringing new technology into your operation can feel like a huge project, but with a bit of planning, implementing your logistics route planning system can be a straightforward and successful move. Think of it less like flipping a switch and more like building a solid foundation for future growth and efficiency. It all starts with taking an honest look at what your business really needs.

This first step is all about assessing your current situation. Don't just search for a generic "route planner." Instead, pinpoint your specific challenges. Are last-minute order changes causing chaos? Are your fuel costs getting out of hand? Do you need to hit precise delivery windows promised to customers? Answering these questions first will help you narrow down the software options to those that solve your actual problems.

Preparing for a Seamless Transition

Once you know what you're looking for, the next crucial step is getting your data in order. Your new system is only as smart as the information you give it. Things like inaccurate addresses, jumbled customer details, and inconsistent data formats are the main reasons these projects stumble.

A common mistake is underestimating the importance of data hygiene. Dedicating time to clean, standardise, and validate your customer addresses and order information before you start can prevent a world of frustration and ensure your new system delivers accurate results from day one.

With your data cleaned up, you can start looking at software seriously. Find a solution that not only handles your current workload but can also grow with your business. For a deeper look into the practical side of things, a comprehensive guide to GPS fleet management can offer great insights into how the hardware and software work together in modern logistics.

Ensuring User Buy-In and Measuring Success

New tech is only half the battle; your people are the other half. Proper training for your dispatchers and drivers is absolutely essential for the system to be adopted successfully. Your drivers need to trust the routes the system plans, and your dispatch team needs to feel confident managing the new workflow. A great way to start is by running a pilot programme with a small, trusted group of drivers to iron out any issues and create some early advocates for the change.

To see how well your new logistics route planning software is working, you need to define your Key Performance Indicators (KPIs) right at the beginning.

- Operational Efficiency: Keep an eye on total kilometres driven, fuel consumption per vehicle, and total driver hours.

- Customer Service: Track your on-time delivery rate and the number of missed or late deliveries.

- Cost Reduction: Calculate the direct savings from reduced fuel use, overtime pay, and vehicle maintenance.

The Carbonpunk platform gives you a clear dashboard for tracking these exact metrics.

Seeing your data laid out like this makes it easy to spot where you're becoming more efficient and where you can still improve. This data-driven approach is also incredibly useful for reporting. For example, platforms like Carbonpunk are built to generate automated sustainability reports for ESG compliance, turning your day-to-day operational data into a valuable asset for regulatory needs. By following these steps—assessing needs, cleaning data, training your team, and tracking KPIs—you can set yourself up for a smooth transition and see a quick return on your investment.

Answering Your Top Route Planning Questions

When you start digging into modern logistics route planning, the same questions tend to pop up again and again. It's completely normal. Getting solid answers to these is the key to figuring out if these tools are right for your business and how they actually work in the real world.

Let's cut through the noise and tackle the most common queries head-on with some straight-talking explanations. My goal is to give you the clarity you need to see how a dedicated system could genuinely help your specific operation.

How Is This Different From Using Google Maps For Routes?

This is easily the most frequent question, and it's a great one. While Google Maps is a brilliant tool for getting a single car from A to B, that’s where its capabilities end. It’s built for personal travel, not for the complexities of commercial logistics.

Dedicated logistics route planning software is playing a completely different ball game. It isn't just finding one route; it’s solving a giant puzzle involving your entire fleet at once.

It has to juggle a whole host of real-world constraints that standard maps just ignore:

- Vehicle Capacity: Is the truck overloaded? Or, just as bad, is it running half-empty?

- Driver Hours: Are you respecting legal driving limits and required break times?

- Delivery Windows: Can you hit that customer's non-negotiable 10 a.m. to 12 p.m. slot?

- Cargo Types: Does this stop require a refrigerated unit or special handling equipment?

The mission of professional software is to slash total fleet mileage and operational costs. That's a universe away from what a simple navigation app is designed to do.

To put it simply: a navigation app finds the best route for one person. Logistics software finds the most efficient routes for your entire team, saving time and money across the whole operation.

What Business Size Truly Needs A Route Planning Tool?

While any business with more than one vehicle can see some benefit, a dedicated tool really becomes a necessity once you hit three or more vehicles. Another clear signal is when your team starts spending over an hour every single day just planning the routes.

But honestly, the real trigger isn't just fleet size—it's complexity.

If you’re constantly battling with tight delivery windows, dealing with last-minute order changes, or managing different service times for various customers, you’ve outgrown manual methods. A dedicated tool becomes critical for keeping things efficient and keeping customers happy, no matter how many vans are on the road.

How Quickly Can We Expect A Return On Investment?

Most businesses I've worked with start seeing a tangible return on their investment (ROI) within three to six months. It often happens faster than people expect.

The first, most obvious wins come from direct savings on fuel and a sharp drop in driver overtime. You’ll likely notice these in the first few weeks. Then, over time, the secondary benefits kick in and compound the ROI, like better customer loyalty from reliable deliveries and lower vehicle maintenance bills from reduced wear and tear. A smooth implementation with good team training is the secret to getting there quicker.

Can Route Planning Software Help Meet Sustainability Goals?

Absolutely. In fact, it's one of the most powerful ways to do it. By its very nature, designing hyper-efficient routes means your fleet travels less. This directly and measurably slashes your fuel consumption and CO₂ emissions.

Platforms like Carbonpunk push this even further. They don’t just find the fastest or cheapest route; they can specifically find the one with the lowest possible carbon footprint. This turns your logistics from a cost centre into a key player in your company's wider environmental, social, and governance (ESG) strategy.

Ready to transform your logistics and hit your sustainability targets? Carbonpunk delivers AI-powered route optimisation and automated CO₂ reporting to cut emissions and drive efficiency. Explore what our platform can do for you.