A Guide to Warehouse Process Improvement

Karel Maly

July 31, 2025

Warehouse process improvement is far more than just tweaking a few things here and there. It’s about taking a hard, honest look at your entire operation and fundamentally re-engineering how you move goods from receiving to shipping. In today's fiercely competitive market, simply running your facility isn't enough; you have to run it intelligently.

Laying the Groundwork for Warehouse Process Improvement

Let's be blunt: effective process improvement isn't a luxury anymore—it's a survival tactic. The pressure to deliver faster and with pinpoint accuracy means that inefficient workflows are a massive liability. The best place to start is by adopting the principles of lean methodology, a philosophy laser-focused on systematically rooting out and eliminating waste.

In a warehouse, this "waste" (often called Muda in lean terminology) isn't just about physical rubbish. It’s the silent killer of productivity, manifesting in costly ways that bleed your resources dry.

Identifying Operational Waste

The first real step is to put on your detective hat and start pinpointing where these inefficiencies are hiding. They often show up in a few common forms:

- Excess Motion: Think about your pickers. Are they walking marathon-like distances every shift because of a confusing layout or nonsensical slotting? Every extra step is wasted time and energy that adds up fast.

- Waiting Time: Idle hands and equipment are a clear sign of a bottleneck. This could be staff waiting for a lorry to be unloaded or a forklift to become free.

- Defects and Rework: This is a huge one. Picking the wrong item is a direct hit to your bottom line and customer trust. It triggers returns, re-picking, and re-shipping—a logistical nightmare.

- Over-production: Holding onto more stock than you actually need ties up capital and eats up precious floor space. That space could be generating revenue, not just gathering dust.

As you start laying this groundwork, don't just look at processes on the floor—look up. Many warehouses are sitting on untapped potential. Exploring smart warehouse mezzanine flooring solutions is a brilliant way to maximise your cubic footage, tackling space constraints head-on without the massive cost of an extension.

For example, I’ve seen a simple redesign of a packing station cut several seconds off every single order processed. Another time, standardising the put-away logic for new stock dramatically slashed the time it took to locate items later. These might sound like small fixes, but they compound into enormous productivity gains over time.

This focus on getting the fundamentals right is particularly crucial in expanding markets. Consider the Czech industrial market, which in Q1 2025 alone added 155,900 square metres of new space, pushing the total modern stock to around 12.44 million square metres. This boom provides a golden opportunity to build advanced, efficient processes right into new facilities from day one.

By tackling these foundational issues first, you’re building a strong, stable base. Your warehouse starts its transformation from a necessary cost centre into an intelligent, efficient engine for your business, paving the way for more advanced tools like automation and AI-driven analytics.

Before you can improve anything, you need a brutally honest look at where you stand right now. Improving your warehouse means first understanding its current reality, warts and all. You can't fix what you haven't measured, and this initial audit is your chance to get past gut feelings and gather the hard data that shows precisely where time, money, and effort are being wasted.

The idea here is to map out your core workflows in detail. This isn't something you do from behind a desk. You need to walk the floor and see every key activity with your own eyes—from a lorry backing into the receiving dock all the way to the final scan before a parcel leaves for shipping. Pay special attention to the handoffs between different tasks or teams. That's where bottlenecks love to hide in plain sight.

Getting a Grip on Your Performance with KPIs

To truly understand what’s happening, you need to track the right metrics. While every operation has its own quirks, some Key Performance Indicators (KPIs) are non-negotiable for a proper health check. They give you a baseline, a starting point from which all improvements are measured.

To help you get started, I've put together a table of the most critical KPIs. Think of this as your diagnostic toolkit for the warehouse floor.

| Key Warehouse Performance Indicators for Your Audit | | :--- | :--- | :--- | | KPI | How to Calculate It | What It Reveals | | Order Picking Accuracy |

(Total Orders - Error Orders) / Total Orders × 100Total Warehousing Costs / Total Number of ShipmentsCost of Goods Sold / Average InventoryTracking these numbers gives you a clear, objective picture of your performance. Whether you use a stopwatch for a specific task or pull complex reports from your Warehouse Management System (WMS), what matters most is that the data is consistent and accurate. This honest assessment is the foundation for every change you'll make later.

Seeing the Potential for Improvement

Once you have this baseline data, the opportunities for improvement will start to jump out at you. This initial snapshot is absolutely essential for building a business case for any new tech or process changes you want to propose. It allows you to shift the conversation from, "I think we could be faster," to a much more powerful statement: "We can cut order processing time by 15%, which will save the company £X this year."

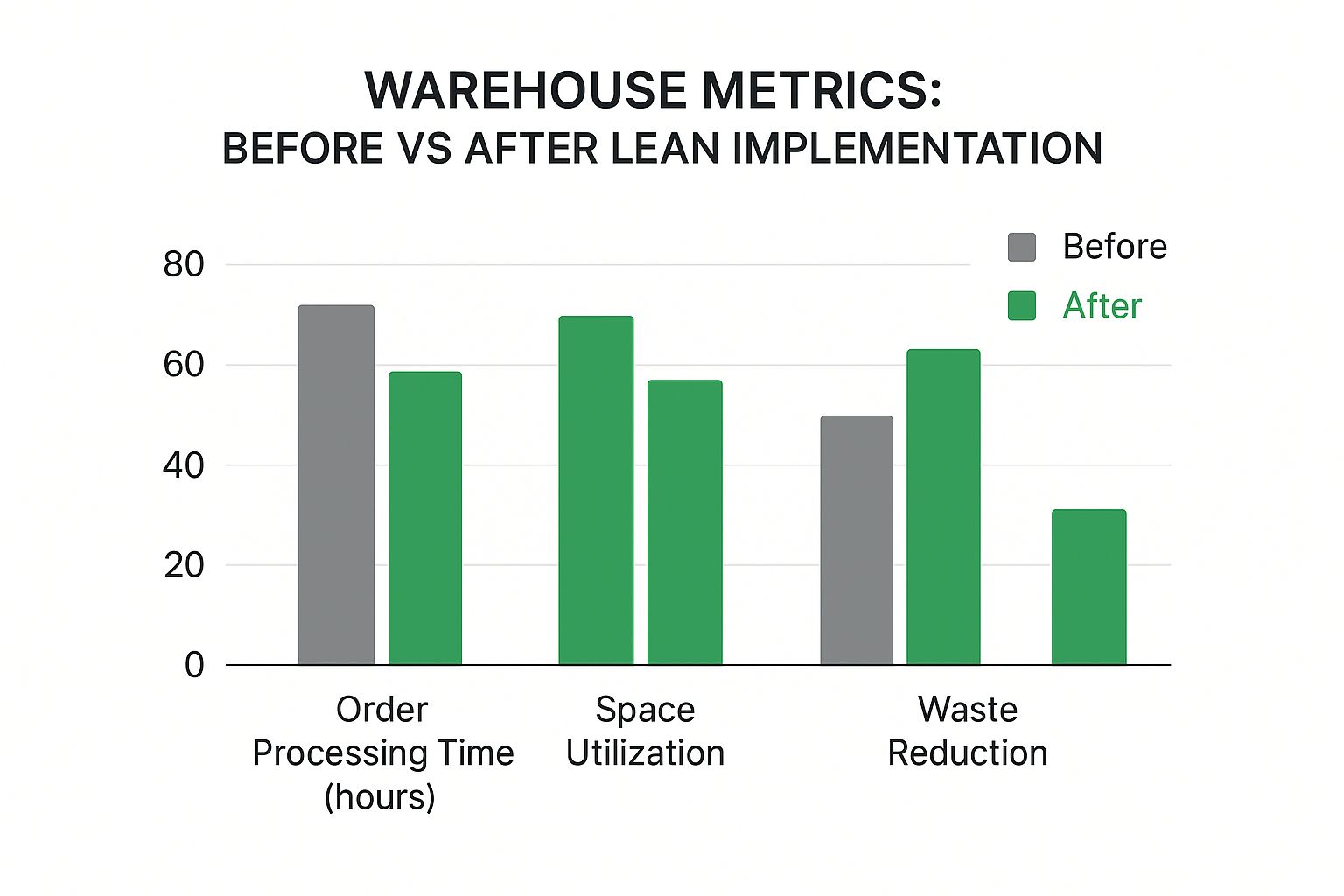

This is where the data becomes a story. For instance, look at the kind of gains you can expect after implementing lean principles.

As you can see, focusing on the right areas can slash processing times, make better use of your space, and significantly cut down on waste.

A great audit doesn't just show you what is wrong; it reveals why. For example, a high dock-to-stock time might not be a labour productivity issue at all. Your audit could uncover that your team is wasting minutes on every pallet, hunting for a place to put it away. Suddenly, you realise you have a slotting problem, not a people problem.

This is the kind of insight that leads to real change. This level of clarity isn't just confined to your warehouse, either. For a closer look at how these principles apply across your entire network, you can learn about mastering supply chain visibility for your business in our related guide. Your audit is the first, and most important, step towards making smarter, data-driven decisions.

Applying Lean Methods on the Warehouse Floor

Putting lean theory into practice is where the real work begins. It’s all about turning abstract concepts into concrete actions that your team can see and feel on the warehouse floor, day in and day out. This is the heart of genuine warehouse process improvement.

A brilliant place to start is with the 5S method. I’ve seen this system work wonders because it’s a simple, powerful framework for creating a clean, organised, and efficient workspace that anyone on your team can grasp and put into action.

Here’s how it breaks down:

- Sort: Go through every corner of the warehouse and get rid of anything that isn't essential for current operations. Be ruthless. If a tool or piece of equipment hasn't been touched in months, it’s just clutter getting in the way.

- Set in Order: Once you’ve cleared out the junk, give everything that remains a specific, logical home. This is where visual cues make a huge difference—think floor markings for pallet placement, shadow boards for tools, and crystal-clear labels on all racking.

- Shine: This is about more than just a quick sweep. It’s a proactive habit of inspecting equipment and the workspace to spot potential issues, like a small oil leak or worn-out parts, before they escalate into a full-blown breakdown.

- Standardise: Now, create clear, consistent procedures for the first three S's. This is crucial for making sure everyone performs tasks the same way, which builds predictability and keeps order from slipping.

- Sustain: Honestly, this is the toughest part. It involves weaving 5S into the very fabric of your company culture through regular audits, feedback, and continuous team engagement.

Building a Culture of Continuous Improvement

Beyond just getting organised, lean is about nurturing a culture of Kaizen, or continuous improvement. This means empowering every single person on your team—from the newest picker to the warehouse manager—to spot small, everyday frustrations and suggest practical fixes. It’s a fundamental shift in mindset from "this is just how we’ve always done it" to "how can we do this better?"

One of the most effective ways I've seen this implemented is through a daily huddle. Just take 10 minutes with the floor team to chat about what went well yesterday and what little "pebbles in their shoes" got in the way. You'll be amazed at the simple, brilliant ideas that come directly from the people doing the work.

This kind of empowerment is critical, especially in the dynamic logistics landscape we see today. In the Czech Republic, for instance, the third-party logistics (3PL) market is projected to grow at a CAGR of 5.00% between 2025 and 2033. This growth is fuelled by a rising demand for sophisticated services, pushing warehouses to adopt smarter processes just to stay competitive. You can get a deeper look into the future of the Czech 3PL market here.

Using Visual Systems for Better Flow

Another lean tool that delivers an immediate impact is a Kanban system. While many people associate it with manufacturing, it’s incredibly effective for managing inventory flow in a warehouse setting. It works by using simple visual signals—like a coloured card or an empty bin—to trigger an action, such as replenishing a specific picking location.

This "pull" system is fantastic because it prevents you from overstocking your picking faces while ensuring you never run out of popular items. It strikes a perfect balance.

The visual nature of Kanban makes it intuitive for staff and cuts down on the need for complex software commands for simple replenishment tasks. This kind of visual management, combined with other lean techniques, serves as a solid foundation for a more advanced, efficient operation. Once you have these basics dialled in, you can explore how a modern logistics route planning guide applies similar principles to the movement of goods outside your warehouse walls.

Choosing the Right Automation and Technology

Once you've built a solid, lean foundation, technology can supercharge your warehouse process improvement efforts. But diving into automation without a clear strategy is a recipe for expensive disappointment. The goal here is to carefully match the right tools to your specific operational problems, making sure technology serves your processes—not the other way around.

Tackling automation should be a gradual, deliberate journey. It's crucial to realise that "automation" isn't one single thing; it’s a whole spectrum of technologies, each built to solve a different kind of challenge.

Nail the Basics First

Before you start dreaming of a fully robotic workforce, you have to get your foundational systems in order. These are the cornerstones of any digitally managed warehouse, providing the raw data you'll need for more sophisticated optimisation down the road.

- Barcode Scanners and RFID: Honestly, this is non-negotiable in the modern era. Accurate, real-time data capture gets rid of manual entry errors and gives you instant visibility of your inventory from the moment it arrives to the moment it ships out.

- A Modern Warehouse Management System (WMS): Your WMS acts as the brain of your entire operation. It organises your stock, directs staff for picking and put-away, and tracks the performance data you need to see what’s working. A good WMS is the central hub for every other piece of tech you bring in.

Think of these tools as creating the digital "map" of your warehouse. Without an accurate map, any advanced navigation tools you add later are basically useless.

In my experience, many operations struggling with what they think are "picking problems" are actually suffering from "data problems." Implementing a solid WMS and scanner system often solves 50% of perceived picking errors simply by giving the team on the floor accurate, real-time information.

Moving on to Smarter Automation

With your foundational tech humming and your processes running lean, you can start looking at more advanced solutions. The key is to target specific tasks—those that are high-volume, repetitive, or prone to error—where automation will deliver the biggest bang for your buck.

A recent survey of warehouse professionals shows a clear trend toward technologies that tackle the most common headaches. Here’s what’s on their radar:

- Autonomous Mobile Robots (AMRs): Unlike older AGVs that just follow fixed magnetic strips on the floor, AMRs can intelligently navigate dynamic environments. They are brilliant for "goods-to-person" setups, where they bring entire shelves of products directly to a picker at a stationary workstation. This single change can slash travel time—often the biggest time-waster in a warehouse.

- Automated Sorters: If you're dealing with high volumes, automated conveyor and sortation systems are a game-changer. They can whip through thousands of packages an hour, sorting them by destination, carrier, or order type. This dramatically boosts throughput at the shipping dock.

- Drones for Inventory Counts: While still an emerging technology, drones are an exciting option for cycle counting. A drone can fly through aisles scanning barcodes or RFID tags, finishing in a few hours what might take a team of people days to do. Best of all, they can often do it with minimal disruption to your daily operations.

Choosing the right tech is all about surgical precision. Instead of a massive, disruptive overhaul, focus on automating the one or two processes causing your biggest bottlenecks. This strategic, phased approach ensures each new piece of equipment delivers measurable warehouse process improvement and builds a strong business case for whatever you decide to invest in next.

Using Data and AI for Predictive Optimisation

If you really want to get ahead, you have to stop putting out fires and start preventing them. This is where moving from reactive fixes to proactive strategies comes into play, and it’s a shift powered almost entirely by data analytics and Artificial Intelligence (AI). This isn’t just about tweaking your current processes; it’s about transforming your warehouse from a simple storage space into a smart, predictive nerve centre.

Think about it: instead of scrambling when you discover a stockout or a picking error, what if you could see it coming? AI-powered tools dig through your historical data and look at what’s happening right now to anticipate the next move. That predictive power is what gives you a truly agile operation.

From Reactive to Predictive Operations

At its heart, using AI is like having a super-powered analyst running endless "what if?" scenarios. The algorithms can test thousands of possibilities to find the most efficient path forward—a task no human team could ever manage.

A great example of this in action is modern AI-powered retail inventory management. These systems do far more than just count what’s on the shelves; they learn your sales cycles and customer behaviours to tell you what you should have in stock, and when.

This single capability sends ripples of positive change across the entire warehouse floor.

- Hyper-Accurate Demand Forecasting: AI can look at seasonality, market buzz, and even upcoming marketing promotions to forecast demand with incredible accuracy. This is your best defence against both the cost of overstocking and the frustration of stockouts.

- Dynamic Inventory Slotting: Picture a warehouse management system that automatically reshuffles your inventory layout based on what’s being picked in real-time. AI can spot which items are frequently bought together and suggest moving them closer to each other or to the packing stations, which dramatically cuts down on how far your pickers have to travel.

- Intelligent Route Calculation: For the people on the floor, AI can instantly map out the most efficient picking route for any batch of orders. It can even account for things like a congested aisle or the current location of other workers to avoid bottlenecks.

Integrating Sustainability with Efficiency

A truly modern take on warehouse process improvement goes beyond just speed and cost savings. It has to factor in environmental impact, too. This is where AI really shows its value, especially when you pair it with platforms designed for carbon tracking.

By linking your AI-driven logistics software with carbon management tools, you get a crystal-clear view of the emissions your warehouse generates. The AI can then find optimisations that cut your costs and your carbon footprint at the same time.

For example, the AI might flag an opportunity to consolidate two half-full shipments heading to the same region or suggest moving certain deliveries to off-peak hours to burn less fuel. This dual focus on operational efficiency and genuine sustainability is no longer a "nice-to-have." For any business serious about this, exploring data-driven sustainability tools is the logical next step.

This push towards smarter, leaner facilities is a trend we're seeing across the market. Here in the Czech Republic, the Q1 2025 data showed industrial warehouse vacancy rates holding steady below 8%. That low number points to incredibly efficient use of existing space and a wider push to modernise logistics infrastructure. This environment is perfect for introducing AI-driven improvements.

Ultimately, when you embrace data and AI, you’re not just fine-tuning what you already do. You’re building a warehouse that can learn, adapt, and anticipate—making sure you’re ready for whatever comes next.

Common Questions About Warehouse Process Improvement

Getting started on a warehouse improvement project can feel like a huge undertaking. It's natural to have questions. I've been in countless warehouses, and I've seen managers grapple with the same initial hurdles time and again. Let's walk through some of the most common ones to give you a clearer path forward.

One of the biggest questions is always the same: where on earth do I begin? The best place to start, without a doubt, is with a thorough audit of what you're already doing. Forget about new tech or big spending for a moment. First, you need a clear map of your core processes—receiving, put-away, picking, packing, and shipping. Get your baseline metrics sorted. What are your order accuracy rates? What’s your dock-to-stock time?

This data-first approach is crucial because it highlights your real pain points. It ensures you’re not just throwing money at a problem, but strategically investing where it will make the biggest difference.

How Do I Get My Team on Board with Changes?

This is a big one. You can have the best plan in the world, but if your team isn't behind it, it’s dead in the water. The secret is getting them involved right from the start. Your people on the floor know the daily grind better than anyone. They know exactly where the bottlenecks are and what drives them crazy. Ask them. You'll be surprised at how practical and effective their ideas are.

When it's time to roll out changes, be crystal clear about the "why." Don't just talk about company goals; explain how this new process or tool will genuinely make their jobs easier, safer, or less frustrating. Frame it in terms of benefits for them.

Here’s a simple tactic that works wonders: celebrate small victories, and do it publicly. Did a new workflow cut the average pick time by 10 seconds? Acknowledge the team's effort. This builds momentum and shifts the culture from seeing change as a top-down order to a shared goal.

Is Warehouse Automation Too Expensive for a Small Operation?

That’s a myth I hear all the time. People picture massive, lights-out facilities run by robots, but automation isn't an all-or-nothing game. It's a spectrum, and the smartest warehouse process improvement strategies begin with affordable tech that solves a specific, nagging issue.

Think about these more accessible starting points:

- Barcode Scanners: This is foundational. They get rid of manual entry errors and are the first step toward having inventory data you can actually trust.

- A Basic WMS: A Warehouse Management System doesn't have to be a multi-million-pound investment. Even an entry-level system can bring incredible order to the chaos, organising stock and directing staff far more efficiently.

- Mobile Picking Carts: These are simple, but they can be a game-changer for picking efficiency, letting your team handle several orders in a single trip.

The point isn't to chase technology for its own sake. It’s about making smart choices that deliver a clear, measurable return on your investment, whether that’s through time saved, higher accuracy, or lower operating costs.

Ready to transform your sustainability reporting from a chore into a competitive advantage? Carbonpunk provides the AI-driven tools to automate your carbon tracking, delivering audit-ready reports and actionable insights to cut emissions. Discover how Carbonpunk can help.