Boost Sustainability with IoT for Real-Time Carbon Emissions Tracking

Karel Maly

August 30, 2025

Imagine trying to steer a ship by looking only at the wake it leaves behind. That’s pretty much what traditional carbon reporting has been for years—a backwards glance at where we've been, long after the course has been set. In the face of our current climate challenges, this slow, after-the-fact approach just doesn't cut it anymore.

Why Old-School Carbon Reporting Is Letting Us Down

For a long time, the standard was annual or quarterly emissions reports. These were cobbled together from old utility bills, historical data, and a fair bit of educated guesswork. While it was a start, the method is fundamentally reactive. It tells you what your carbon footprint was, not what it is or where it's headed.

This delay creates massive blind spots. By the time a report lands on a decision-maker's desk, the operational issues that caused those emissions are ancient history. The chance to step in, fix an inefficiency, or stop a sudden spike has vanished. It’s a bit like a doctor trying to treat a patient today using a medical chart from last year—the information is just too stale to be useful.

The Trouble with Yesterday's Data

The real problem with historical reporting is that it doesn't empower anyone to make a change now. When your data is old, you can't be agile. This old-fashioned method creates a few key headaches:

- Delayed Reactions: A piece of equipment could malfunction and start guzzling energy, but it might go unnoticed for months. That’s a lot of preventable emissions and wasted money.

- Fuzzy Benchmarks: Annual averages smooth over the daily or seasonal peaks and valleys in emissions, hiding the real story of what drives them.

- Poor Accountability: It's tough to connect a specific operational change to a real drop in emissions without continuous data to back it up.

- No Real Insight: Companies lose the ability to spot patterns or predict future emissions, which kneecaps any serious long-term sustainability strategy.

Moving to dynamic monitoring isn't just a simple upgrade; it's a fundamental shift in thinking. Real-time data turns carbon emissions into a key performance indicator you can manage actively, just like you would with production targets or financial results.

Moving Towards Proactive Management

The need for a more immediate, dynamic system is undeniable. Here in Central Europe, and especially in the Czech Republic, using IoT for real-time carbon emissions tracking is starting to pick up steam. We're seeing pilot projects pop up that use sensor networks to deliver immediate data, helping to tackle urgent climate goals head-on. This is crucial, especially since the 2025 Climate Performance Index placed the country 49th globally, highlighting the need for better tracking to hit EU targets. You can dig into these climate performance insights over at ccpi.org.

To genuinely leave outdated carbon reporting behind, organisations need data they can trust and act on. IoT provides that solid foundation, paving the way to Master Corporate Social Responsibility Reporting Strategies that are both transparent and effective. A truly forward-thinking strategy demands instant insights, and that’s where connected devices completely change the game.

How IoT Carbon Tracking Systems Actually Work

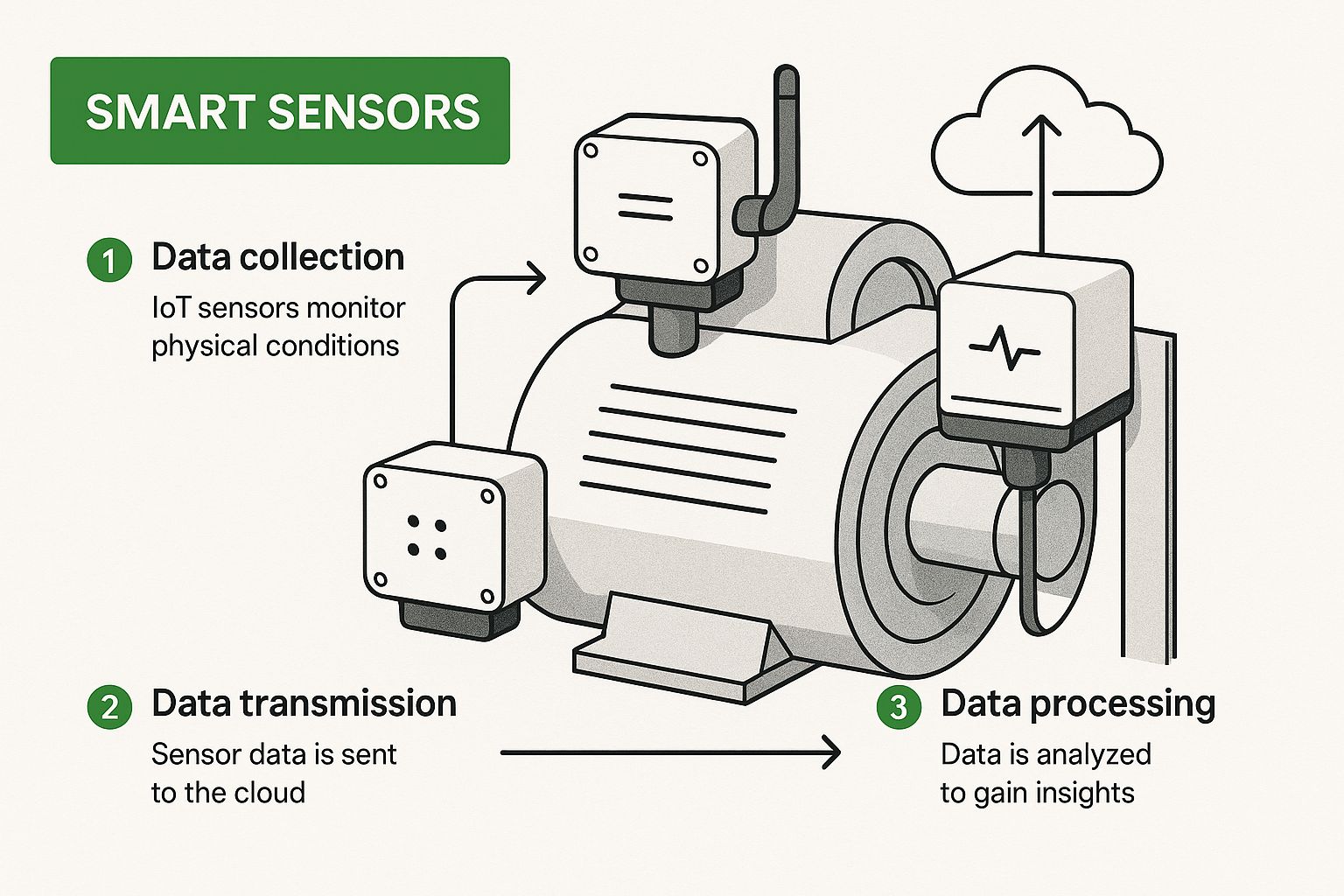

To get a real feel for how IoT tracks carbon emissions, picture it as a digital nervous system for the environment. It senses what’s happening, communicates that information, and instantly processes it. This system turns invisible gases into data you can actually see and manage. The entire process breaks down a complex problem into four clear, logical steps, turning a single puff of industrial smoke into a critical insight on a dashboard.

It all starts right at the source of the emissions. That could be a factory smokestack, the exhaust from a fleet of delivery vans, or even a specific piece of machinery on a production line. The first job is simple: detect and measure.

The First Step: Sensing and Capturing Data

At the very heart of any IoT tracking network are specialised smart sensors. Think of these as the system's "digital nose," meticulously designed to sniff out and measure specific greenhouse gases like carbon dioxide (CO₂) or methane (CH₄).

Different jobs call for different sensors. A rugged Nondispersive Infrared (NDIR) sensor might be perfect for a harsh industrial plant, while a smaller electrochemical sensor would be better suited for mobile assets like vehicles. These devices don't just sit there; they are constantly sampling the air, converting chemical readings into digital signals. Each one of these raw data points is the fundamental building block of the entire system.

This image shows how these sensors are the first crucial link in the chain, grabbing data directly from the source.

As the diagram illustrates, it all begins with precise measurement. Without good data coming in, everything that follows is meaningless.

The Second Step: Transmitting the Information

Once a sensor takes a reading, that tiny piece of data needs to get from point A to point B. This is where the network comes in. The sensor first sends its data to a local gateway—a device that acts like a neighbourhood post office, collecting information from all the nearby sensors.

This gateway then bundles up the data and sends it on to a central cloud platform. Choosing the right communication technology is vital and depends entirely on the situation:

- LoRaWAN: Perfect for sending small bits of data over very long distances without using much power. It's ideal for remote locations or sprawling industrial sites.

- NB-IoT: This is a cellular technology that gets a strong signal even in tricky spots like basements or dense urban centres.

- 5G: When you need massive bandwidth and almost zero delay, 5G is the answer. It’s for applications that require near-instantaneous analysis and response.

This secure journey ensures the data arrives intact and ready for the next stage.

The Third Step: Processing and Analysing in the Cloud

At this point, we have a massive stream of raw numbers flowing in from potentially thousands of sensors. By itself, it’s not very useful. The real magic happens when this data hits the cloud platform—the "brain" of the operation.

Here, powerful algorithms and machine learning models get to work. They clean up the data, filter out any strange readings, and start to identify patterns and trends that a human would never be able to spot.

This is where context is added. The platform might connect a spike in emissions from a factory to its production schedule or link higher traffic emissions to a specific time of day. The analytical engine is what transforms raw measurements into truly actionable intelligence.

To understand the core technology, it helps to see how the different layers work together.

Core Components of an IoT Carbon Tracking System

This table breaks down the essential technological layers that enable real-time carbon emissions monitoring, from data capture to analysis.

| Component Layer | Function | Example Technologies |

|---|---|---|

| Sensing Layer | Captures raw environmental data at the source. | NDIR, Electrochemical, and Optical Sensors |

| Network Layer | Transmits data from sensors to the central platform. | LoRaWAN, NB-IoT, 5G, Wi-Fi |

| Processing Layer | Aggregates, cleans, and analyses the incoming data stream. | Cloud Platforms (AWS, Azure), Edge Computing |

| Application Layer | Visualises insights and enables user interaction. | Dashboards, Mobile Apps, Alert Systems |

Each layer builds on the last, creating a seamless flow from a physical measurement to a strategic business decision.

The Final Step: Visualisation and Action

The last piece of the puzzle is presenting all these complex insights in a way that’s simple and easy to understand. This is usually done through an interactive dashboard, a detailed report, or a mobile app. The people making the decisions aren't looking at spreadsheets full of numbers; they're seeing:

- Heatmaps that pinpoint emission hotspots across a facility or city.

- Trend lines that show how they are performing against their reduction targets.

- Automated alerts that flag an equipment malfunction or a compliance issue in real time.

This intuitive approach gives everyone—from a factory manager to a city planner—the power to make smart, data-driven decisions to cut their carbon footprint. The principles are similar to other data-heavy applications, and you can see a parallel in how solar technology leveraging AI and IoT uses data to optimise performance. Ultimately, the process makes environmental impact tangible and, most importantly, manageable.

Choosing the Right Sensors and Network Technology

The success of any IoT carbon tracking project really comes down to its physical foundation—the hardware that actually gathers and sends the data. It's a bit like building a house; if the foundation isn't solid, everything you build on top of it is at risk. Getting the sensor and network choices right from the start is absolutely crucial for ensuring your data is both accurate and trustworthy.

This isn't just about buying the most advanced or expensive gear. It’s about making a smart match between the technology and the specific environment you're working in. A sensor that performs brilliantly in a clean, climate-controlled factory might completely fail when it’s stuck on a remote pipeline and exposed to the elements.

Selecting the Best Gas Sensors for the Job

Think of sensors as the eyes and ears of your IoT system. They’re on the front lines, responsible for detecting and measuring greenhouse gases with precision. For carbon tracking, two types tend to dominate the field: Nondispersive Infrared (NDIR) and electrochemical sensors. Each has its place.

Nondispersive Infrared (NDIR) Sensors are often considered the gold standard for measuring CO₂, especially when accuracy and a long operational life are top priorities. They work by passing infrared light through an air sample and measuring how much of that light is absorbed by CO₂ molecules. This method is incredibly stable and isn't easily thrown off by other gases, making NDIR sensors perfect for fixed installations like factory smokestacks or inside building ventilation systems where you need reliable, long-term monitoring.

On the flip side, you have Electrochemical Sensors. These are typically smaller, cheaper, and use a lot less power. They work by detecting gases through a chemical reaction that produces a tiny electrical current. While they might need calibrating more often than their NDIR counterparts, their small size and efficiency make them ideal for mobile uses, like tracking emissions from a fleet of delivery vans or monitoring air quality across a city.

The real takeaway here is that sensor selection is all about trade-offs. You'd prioritise NDIR for high-stakes, stationary monitoring where accuracy is everything. But for mobile applications or large-scale deployments where cost and power are the main concerns, electrochemical sensors are often the smarter choice.

Understanding this distinction is the first step toward building a system that actually works in the real world.

Pairing Sensors with the Right Network

Once a sensor takes a reading, that piece of data needs a way to get back to your analytics platform. The network technology you choose acts as the communication backbone for the entire operation. This decision is a balancing act between range, power consumption, how much data you can send, and, of course, cost.

Here’s a look at the most common connectivity options for IoT carbon tracking:

-

LoRaWAN (Long Range Wide Area Network): This technology is fantastic at sending small bits of data over very long distances—we’re talking several kilometres—while sipping battery power. This makes it a go-to choice for sprawling industrial sites, large farms, or any remote infrastructure where running power cables just isn't feasible.

-

NB-IoT (Narrowband-IoT): Because it operates on existing mobile networks, NB-IoT is great at getting a signal into hard-to-reach places, like deep inside buildings, basements, or dense urban canyons. It provides a secure and reliable connection for sensors that need to consistently phone home from tricky spots without you having to build a new network.

-

5G and Cellular LTE: When you need to move large amounts of data very quickly with almost no delay, 5G is the clear winner. It's best for complex jobs that might involve real-time video or high-frequency data streams, like monitoring a busy shipping port. Standard LTE, meanwhile, offers a solid and reliable middle ground for many mobile tracking needs.

Nailing the right combination of sensor and network technology is the cornerstone of a robust and effective IoT system. By carefully thinking through the demands of your specific environment, you can build a reliable infrastructure that delivers the precise, real-time data needed to drive real climate action.

Turning Raw Data Into Actionable Climate Insights

A constant stream of raw sensor readings is like static on the radio—it's just noise until you tune it to the right frequency. The real magic of IoT for real-time carbon emissions tracking happens in the analysis phase, where this digital noise is turned into clear, strategic intelligence. This is where the technology stops just measuring and starts delivering genuine climate insights.

At the heart of this are powerful analytics engines, often built on artificial intelligence (AI) and machine learning. Think of them as the brains of the operation. These systems sift through millions of data points every second, doing the heavy lifting that would be completely impossible for a human team. They don't just count emissions; they understand the story behind them.

This analytical process is what flips the switch from a passive monitoring system to an active management tool. It’s the difference between knowing your emissions exist and knowing exactly what to do about them.

From Numbers to Narratives with AI

Artificial intelligence algorithms are fantastic at finding the "story" hidden in the data. They hunt for patterns, correlations, and strange outliers that reveal the true drivers of an organisation's carbon footprint. This gives you a much deeper understanding of what's really going on.

For instance, an AI model might spot a sudden spike in a factory's emissions and link it to a specific machine operating outside its normal parameters. This isn't just a number on a chart; it's an immediate, actionable alert. It signals a need for maintenance before the problem gets worse, saving both energy and money.

These intelligent systems are particularly good at a few key things:

- Identifying Emission Hotspots: AI can comb through data from thousands of sensors to pinpoint the exact locations, processes, or equipment causing the highest emissions.

- Detecting Anomalies: Machine learning algorithms learn what "normal" looks like for your operations. They can instantly flag any deviation that might signal a gas leak, equipment failure, or an inefficient process.

- Predicting Future Trends: By looking at historical data alongside things like weather forecasts or city traffic patterns, these systems can forecast future emission levels. This allows you to plan ahead instead of just reacting.

This level of detail is a game-changer. It helps organisations move from vague, company-wide reduction goals to precise, surgical actions that deliver real results.

The goal is to make emissions data as intuitive and manageable as any other business metric. When you can see a direct link between an operational decision and its carbon impact in real time, you empower your teams to make smarter, more sustainable choices every day.

Ensuring Data Accuracy Through Cross-Validation

Even the best sensors can have a bad day. To build a system that leaders can actually trust, you can't rely on raw IoT data alone. The smart move is to cross-reference it with other independent data sources to confirm its accuracy and add layers of context.

This process, sometimes called data fusion, creates a much more complete and reliable picture. A great large-scale example is the Carbon Monitor Europe project, which gives daily CO₂ emission estimates for EU countries. While it mostly relies on satellite and mobility data, imagine how much more granular it could be by integrating local IoT sensors in places like the Czech Republic. Industrial IoT could feed it hourly factory emissions, enriching those regional estimates and creating a powerful, multi-layered tracking infrastructure. You can learn more about how these advanced data models are shaping European climate policy.

Visualising Insights for Decisive Action

The final, crucial step is presenting all this sophisticated analysis in a way that people can actually use. Complex insights are worthless if they're buried in a spreadsheet. The best IoT platforms use customisable dashboards and automated alerts to get the right information to the right person at the right time.

This is what turns data into decisions. A logistics manager might see a live map highlighting the most carbon-intensive delivery routes. A sustainability officer could get an automated report summarising monthly progress towards reduction goals. By making the data accessible, organisations empower leaders to stop reacting to yesterday’s problems and start proactively managing their carbon footprint. For companies ready to take the next step, leveraging carbon data automation for companies boosts efficiency today by plugging these insights directly into day-to-day workflows.

Real-World Applications and Tangible Benefits

Theory is one thing, but the real magic of using IoT for carbon emissions tracking happens when you see it in action. This isn't just about crunching numbers for an annual report; it's about making real, measurable changes across industries. For a business, it means running a tighter ship and gaining a competitive advantage. For a city, it means creating a healthier, more sustainable place to live.

The upsides are clear, offering a powerful return for both the planet and your profit margins. When emissions become a live, manageable metric, organisations can finally stop guessing and start making smart decisions based on hard data—slashing waste, cutting costs, and becoming more resilient.

Smarter Logistics and Greener Supply Chains

The logistics industry is a perfect example of where this technology delivers immediate, tangible results. Supply chains are famously complex, with countless moving parts that all contribute to their carbon footprint. By fitting IoT sensors onto vehicles, shipping containers, and inside warehouses, you get a live, breathing picture of the entire operation.

Imagine a logistics company using this data to map out cleaner, faster delivery routes on the fly, dodging traffic jams that cause engines to idle and burn unnecessary fuel. This approach unlocks several key advantages:

- Dynamic Route Optimisation: Smart algorithms can analyse live traffic, weather, and vehicle data to pinpoint the most fuel-efficient routes, cutting CO₂ emissions with every single delivery.

- Fuel Consumption Monitoring: Instant alerts can flag wasteful driving habits, like sudden acceleration or leaving the engine running, which helps in training drivers to be more efficient.

- Proof of Sustainability: With verifiable, real-time data, companies can genuinely prove their green credentials to customers and investors, which is a massive differentiator in the modern market.

Building Sustainable and Responsive Smart Cities

For city planners and local governments, IoT provides the detailed, street-level data needed to build smarter, more enjoyable cities. Deploying sensor networks across the urban environment allows them to pinpoint pollution hotspots and understand their root causes with stunning clarity.

This is what enables effective, targeted policies. For example, a city could use live air quality data to activate low-emission zones only when pollution levels spike. It could also identify which public buildings are wasting energy on heating or cooling and prioritise them for upgrades. Real-time carbon emissions tracking is crucial for proving the impact of major investments, like those funded by the national Greenhouse Gas Reduction Fund.

By transforming urban areas into responsive ecosystems, IoT empowers city leaders to improve public health, optimise infrastructure, and create policies that are both effective and fair.

Enhancing National Climate Strategies

On a national scale, real-time data can completely change how countries tackle their climate commitments. Take the Czech Republic's 2023 National Inventory Report, which showed that CO₂ made up 82.9% of the country's total greenhouse gas emissions. Right now, this reporting is based on annual data sets. Integrating IoT would provide the continuous, up-to-the-minute insights needed to make faster policy tweaks in critical sectors like energy and industry. You can dig into the full official UNFCCC submission for more details.

Making the switch from static annual reports to dynamic, live monitoring is a game-changer for any nation serious about accelerating its climate action. When you pair this flow of data with a powerful management system, it becomes an indispensable tool. You can learn more about how a decarbonisation platform can boost your climate strategy and help turn these insights into real progress towards net-zero.

Navigating the Real-World Hurdles of Implementation

Putting an IoT system in place for real-time carbon tracking is a game-changer, but let's be honest—it’s not a simple plug-and-play affair. Like any serious tech upgrade, it comes with its own set of predictable challenges. Knowing what’s coming and having a solid game plan is what separates a successful, long-term asset from a frustrating pilot project that never gets off the ground.

It all starts with the hardware. If you can't trust the data coming from your sensors, the entire system is built on a shaky foundation. From there, you have to think about keeping that data safe, making sure the system can grow with your company, and, of course, managing the upfront costs.

You're Only as Good as Your Data

The fastest way for an IoT project to fail is with bad data. If your sensors aren't giving you accurate readings, every dashboard, report, and strategic decision you make is compromised. Getting this right is job number one.

A common culprit here is sensor drift, which is just a fancy way of saying a device's measurements get less accurate over time because of wear and tear or environmental conditions. The single most effective countermeasure? A strict, non-negotiable calibration schedule. This means regularly testing your sensors against a known, trusted standard and making adjustments. If you skip this, you’re flying blind.

It’s also smart to build in some checks and balances. You could install a couple of sensors on a critical piece of equipment instead of just one, or even cross-reference your new IoT data with old-school sources like utility bills or fuel logs. If the numbers don't line up, you know it's time to investigate.

Planning for Growth and Security

A system that works perfectly for a handful of sensors can completely fall apart when you scale up to hundreds or thousands. You have to design for growth from the very beginning, or you’ll be facing a very expensive and disruptive overhaul later on.

The best way to do this is with a modular architecture. Think of it like building with Lego blocks; you can add new sensors, new facilities, and new features one piece at a time without having to tear down what you've already built. A phased rollout also makes the initial investment much easier to swallow, allowing you to prove the concept and get buy-in before going all-in.

Security isn't a feature you can bolt on at the end. It has to be baked into the system from the start. With thousands of devices sending data, your attack surface grows exponentially.

Make sure all your data is encrypted, both when it's sitting on a server and when it's travelling over the network. Robust access controls are just as critical—you need to be certain that only the right people can see or change your emissions data.

Best Practices for Getting it Right

Navigating these challenges really just comes down to smart planning and a methodical approach. Here are a few essential practices to keep in mind as you get started:

- Start Small, Win Big: Kick things off with a focused pilot project. Pick one area of your operation to prove the technology works, iron out the wrinkles, and demonstrate a clear return on investment before you even think about a full-scale deployment.

- Insist on 'Secure-by-Design': Partner with vendors who treat security as a core component of their product, not an afterthought. Ask them how they build security into their hardware and software from the ground up.

- Let the System Do the Work: Use the platform's power to automate alerts and reporting. This frees up your team from manual, repetitive tasks and ensures you can react instantly when something goes wrong, like an equipment failure causing an emissions spike. Maximising your investment by generating automated sustainability reports for ESG compliance is a perfect example of this.

Frequently Asked Questions

When you start digging into how IoT can track carbon emissions in real time, a few key questions usually pop up. Let's tackle the most common ones—accuracy, cost, and how it all fits with regulations—to give you a clearer picture.

How Accurate Is This Stuff, Really?

The accuracy of an IoT tracking system really comes down to the quality of its sensors and how well they're looked after. If you're using professional-grade hardware, like Nondispersive Infrared (NDIR) sensors for CO₂, you can expect a very high level of precision—usually within a 2-5% margin of error.

But good hardware is only half the story. The best systems don't just trust one source of information. They cross-reference sensor data with other streams, and smart algorithms clean up the data by spotting and filtering out any weird readings or errors. This process gives you a rock-solid dataset that you can actually trust to make important decisions.

What Does a System Like This Typically Cost?

There's no single price tag for an IoT carbon tracking system; it really depends on how big and complex you want to go. A small pilot project to test the waters could cost just a few thousand euros. On the other hand, a full-blown system across an entire city could easily run into the millions.

The final cost is shaped by a few main things:

- Sensors: How many you need and what quality they are.

- Connectivity: The monthly or annual fees for data plans, whether it's LoRaWAN, NB-IoT, or a standard cellular network.

- Platform Fees: Subscription costs for the cloud software that crunches the numbers and presents the data.

- People Power: The cost of getting everything installed and keeping it all calibrated and running smoothly.

Even with the upfront costs, many organisations find the investment pays off handsomely through lower operating costs, better efficiency, and fewer headaches with compliance.

The true value isn't just about the initial outlay. It's about the operational efficiencies and risk reduction it brings. A well-designed IoT system often pays for itself by pinpointing expensive energy waste and helping you sidestep hefty compliance fines.

How Does This Technology Help with All the Rules and Regulations?

This is where IoT really changes the game. It transforms compliance from a manual headache into an automated, data-driven process. Instead of guessing with annual estimates and complicated spreadsheets, you can generate precise, real-time emissions reports automatically.

This automation makes it much easier to stick to standards like the GHG Protocol. More importantly, it helps you spot potential problems early and fix them before they become costly violations. This doesn't just cut down on the risk of fines; it also gives your organisation’s environmental, social, and governance (ESG) credentials a serious boost.

Ready to turn your carbon management from a chore into a real strategic asset? Carbonpunk provides an AI-driven platform that gives you the accuracy and automation needed to hit your sustainability targets. Discover how Carbonpunk can streamline your emissions tracking today.