Discover Circular Economy Software Solutions for Sustainable Growth

Karel Maly

September 27, 2025

Circular economy software is, in simple terms, the digital toolkit that businesses use to stop wasting resources and keep materials cycling through the economy. Think of it as the command centre for tracking everything from raw materials to finished goods, managing their entire lifecycle, and ultimately turning what used to be trash into a valuable asset.

From Linear Waste To Circular Value

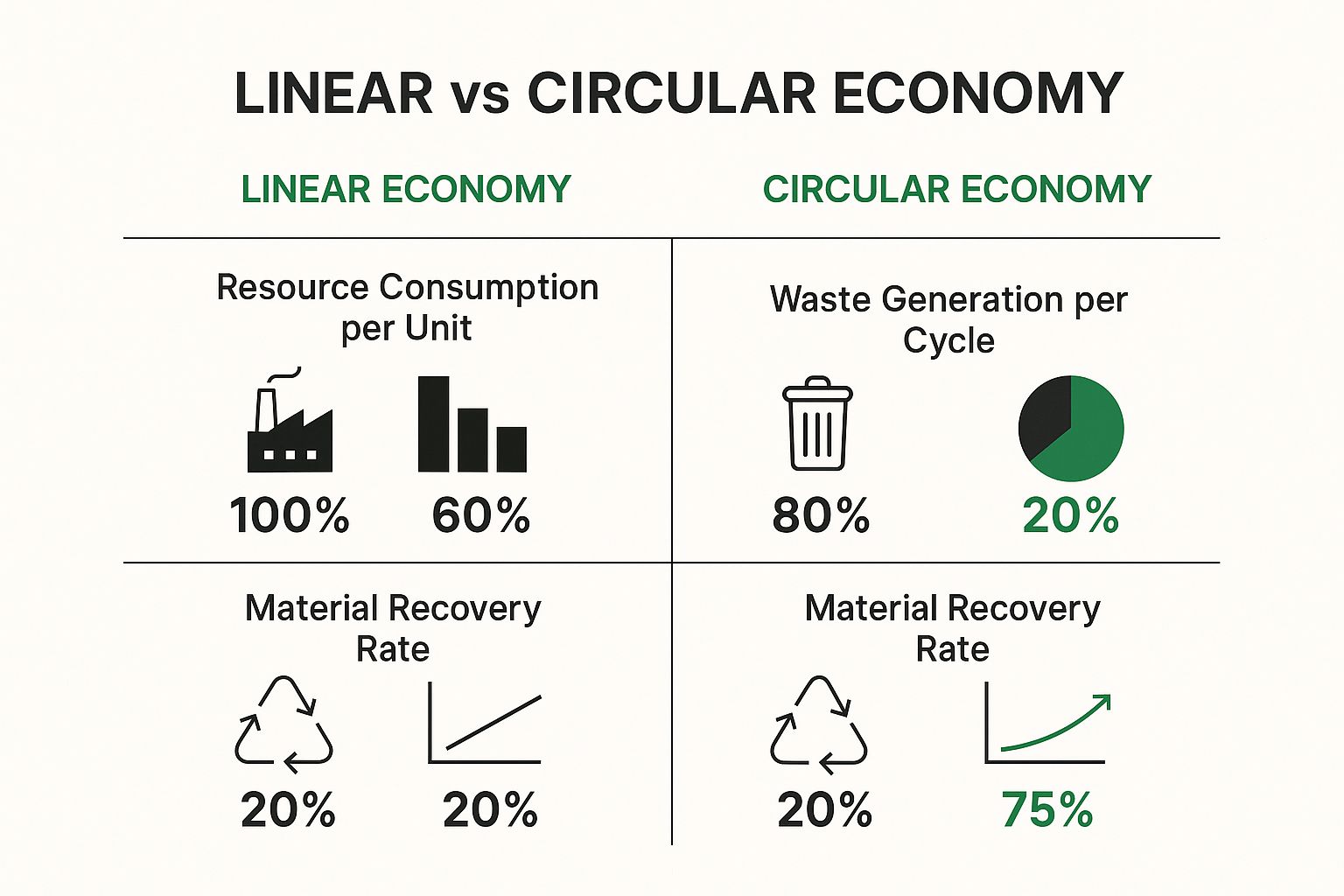

Most businesses have traditionally operated on a straight line. You take resources, make a product, and then somebody throws it away. It’s a leaky pipe—you pour valuable materials in one end, and waste just pours out the other. We call this the "take-make-waste" linear model, and it's a system we're quickly realising we can't afford anymore.

Now, imagine a completely different system. Instead of a leaky pipe, you have a closed loop. Every drop is captured, cleaned up, and sent right back to the beginning. That's the essence of the circular economy. It's a model built to restore natural systems, keep products in use for as long as possible, and design waste out of the picture from day one.

But managing this constant, cyclical flow of materials isn't simple. It demands some serious digital smarts. This is exactly where circular economy software solutions come in, giving businesses the oversight and control they need to make the circular model a reality.

The data here really highlights the stark difference: the old linear way is incredibly wasteful, while the circular approach is all about preserving precious resources.

The Digital Engine Of Sustainability

You can think of this software as the brain and central nervous system of a circular business. It connects every single stage of a product's life, from the first sketch to its final recovery, feeding you the data needed to make smart, waste-free decisions. Honestly, trying to run a large-scale circular operation without this digital backbone would be a logistical nightmare.

Here’s what these platforms help businesses do:

- Track materials meticulously: Follow every screw, fabric, and polymer through the supply chain to make sure it can be recovered, reused, or properly recycled later.

- Optimise product design: Use data to design products that are actually built to last—easy to repair, simple to refurbish, and designed for disassembly.

- Manage reverse logistics: Handle returns, take-back programmes, and recycling with real efficiency, capturing the maximum value from used products.

- Ensure transparency: Provide solid, verifiable data on a product's journey and environmental footprint. This builds huge trust with both customers and regulators. A key innovation here is the Digital Product Passport, which acts as a detailed logbook for a product's entire life. You can learn more about how Digital Product Passports are transforming supply chains now.

The table below breaks down the fundamental shift in thinking between the old and new models.

Linear vs Circular Economy Business Models

| Aspect | Linear Model (Traditional) | Circular Model (Software-Enabled) |

|---|---|---|

| Goal | Maximise production and sales | Maximise resource value and longevity |

| Resource Flow | Take → Make → Dispose | Recover → Remake → Reuse |

| Product End-of-Life | Landfill or incineration | Disassembly, refurbishment, recycling |

| Business Focus | Selling new units | Providing services, leasing, take-back |

| Data Usage | Primarily sales and operations | Tracks full lifecycle, material data |

| Customer Role | Consumer | User, partner in recovery |

As you can see, the circular model, powered by software, completely reframes the relationship between a business, its products, and its customers.

Growing Demand In Czechia

This isn't just a far-off global trend; it's happening right here in the Czech Republic. Czech businesses are increasingly adopting circular principles, and a big reason is that their customers are demanding it. A 2017 survey showed that 68% of Czech consumers are willing to spend more on eco-friendly products, a number that jumps to 72% among young people. This enthusiasm, combined with new commitments from major companies, points to a massive opportunity for businesses ready to invest in circular economy software.

It’s about moving past the simple "reduce, reuse, recycle" mantra. The real goal is to create a system where waste simply isn't an option, and every material is seen for its ongoing value.

At the end of the day, these software tools aren't just about "being green." They are powerful strategic instruments for building more resilient, efficient, and profitable businesses that are ready for the future.

Core Features of Modern Circularity Software

To really get what circular economy software solutions are all about, we need to pop the bonnet and see what makes them tick. These platforms are a world away from simple spreadsheets; they're powerful engines designed specifically to manage the complex, looping journey of materials. Each feature plays a part in bringing clarity and control over resources that would otherwise be lost in a straight-line, disposable system.

Think of these features as the different sections of an orchestra. Each one has a distinct job, but when they work together, you get a perfectly synchronised system. Let's break down the essential components that really define this kind of software.

Material Traceability And Transparency

At the very heart of any circular model is knowing exactly where your materials are, at any given moment. Material traceability is like a GPS tracker for every single component in your product. It follows a resource right from its origin, through production and its life with the customer, and all the way back into the loop through recycling or repair.

This kind of detailed tracking is absolutely critical. It gives you the hard data you need to verify the recycled content in a new product, prove you’re sourcing responsibly, or ensure that hazardous materials are handled properly at the end of their life. A fashion brand, for instance, could use it to prove its shirts are made from certified organic cotton and then show customers exactly how to return them for recycling.

This level of transparency isn't just a "nice-to-have" anymore. It's quickly becoming a ticket to play, essential for building customer trust and getting ahead of new regulations like the EU's Digital Product Passport.

Lifecycle Assessment Tools

So, if traceability tells you where a material is, Lifecycle Assessment (LCA) tools tell you its environmental story. An LCA feature is basically an environmental impact calculator. It measures a product's total footprint across its entire existence—from the moment raw materials are pulled from the earth ("cradle") to its final destination, be it recycling or disposal ("grave").

This is an incredibly powerful analysis that helps you pinpoint the environmental hotspots in your value chain. A food company might use an LCA module and discover that a staggering 80% of its packaging's carbon footprint comes from making the virgin plastic. Armed with that knowledge, they can make an informed switch to a lighter, recycled alternative and immediately shrink their impact. It's a core function for many, as we explore in our guide to climate software for product teams.

Ultimately, these tools give you the evidence you need to make credible sustainability claims and bake eco-design principles into your products from day one.

Reverse Logistics Management

Getting products back from customers is genuinely one of the biggest operational headaches in the circular economy. This is where reverse logistics management features are indispensable. They orchestrate the entire take-back process, from handling customer returns and scheduling collections to sorting used products and sending them to the right place for repair, remanufacturing, or recycling.

Without this, a take-back scheme can quickly descend into a costly, chaotic mess. A good reverse logistics module helps a business:

- Optimise collection routes to slash transport emissions and fuel costs.

- Track the condition of returned items to figure out their best next use.

- Manage the inventory of returned goods and salvaged components.

An electronics company, for example, can use this to manage its old device take-back programme. It ensures old phones are collected efficiently and stripped for valuable metals that can go straight into new products. Many platforms now integrate advanced real-time data analytics to make these logistics smarter and more predictive.

By truly mastering that return journey, companies can unlock huge value from products that were previously destined for landfill. Together, traceability, LCA, and reverse logistics form the backbone of effective circular economy software, turning big ideas into tangible, operational results.

How Circular Software Drives Business Growth

The environmental case for a circular economy is solid, but let's be honest—the big question for any business leader is always about the bottom line. What will this actually do for us? The good news is that adopting circular economy software solutions isn't just a feel-good sustainability project; it’s a hard-nosed strategy for real growth and building a business that can weather future storms.

These tools fundamentally shift sustainability from being a cost centre to a core part of how you create value. By giving you a crystal-clear view of where every resource is going, they uncover efficiencies and money-making opportunities that were completely hidden before. This is about building a smarter, more profitable business from the inside out.

Cutting Costs Through Resource Optimisation

The first and most obvious win is a sharp reduction in waste. In the old linear model, every bit of material that ends up in a skip is a sunk cost—you paid for the raw material, the energy to process it, and the labour to handle it, only to throw it away.

Circular software gets right to the heart of this problem. By tracking materials from the moment they arrive to their end-of-life, it lets companies see exactly where value is leaking out. A manufacturer might discover that 15% of a specific raw material is being lost as offcuts during production. With that data, they can fine-tune their processes, potentially saving thousands of euros every year.

The thinking here is simple but powerful: waste is just a resource in the wrong place. This software provides the intelligence to put every resource where it can generate the most value, over and over again.

This leads to direct savings across the board:

- Reduced Raw Material Spend: When you reuse and recycle materials internally, you buy less from outside suppliers, shielding your business from volatile commodity prices.

- Lower Waste Disposal Fees: Sending less to landfill directly translates to smaller disposal bills and a lighter environmental tax burden.

- Optimised Energy Consumption: A more efficient flow of materials almost always results in lower energy consumption, which is another big win for the budget.

Enhancing Brand Reputation And Customer Loyalty

In a market like Czechia, where consumers are increasingly eco-conscious, a genuine sustainability story is a major competitive advantage. People are actively looking for brands that reflect their own values, and circularity gives you an authentic, compelling story to tell.

This is where circular economy software becomes your proof. It provides the transparent, verifiable data you need to back up your green claims. You can move beyond vague marketing slogans and show customers the actual journey of recycled material in your product or offer a seamless take-back service. That builds a level of trust that a generic "eco-friendly" label simply can't compete with.

This transparency creates incredible customer loyalty. When you make it easy for people to participate in the circular journey—whether through repairs, returns, or refills—you create a relationship that lasts far longer than a single purchase. You're not just selling a product; you're building a community around a shared commitment to a better way of doing things.

Unlocking New Revenue Streams

Perhaps the most exciting part is how this software opens up entirely new ways to make money. By shifting your thinking from just selling products to managing their entire lifecycle, you can create value in places you never thought to look before.

Think about these new business models, all made possible by smart circularity software:

- Product-as-a-Service (PaaS): Instead of selling a high-end appliance, you lease it. The software keeps track of the machine's location, usage, and health, telling you exactly when it needs to be brought back for maintenance, refurbishment, and redeployment. You maximise its lifetime value and secure recurring revenue.

- Remanufacturing and Refurbishment: The software’s reverse logistics tools help you efficiently get used products back from customers. You can then remanufacture them to a "like-new" condition and sell them at a fantastic margin, creating a profitable second-life market.

- Material Resale: By identifying and sorting high-quality secondary materials from your own waste streams, you can sell them on to other industries. Suddenly, what used to be a disposal cost is now a new income stream.

Ultimately, these platforms give you the operational backbone to turn theoretical circular models into real, profitable parts of your business. They’re an investment not just in sustainability, but in future-proofing your growth.

Overcoming Common Implementation Hurdles

Let's be honest, bringing in any new technology can feel like a major upheaval, and circularity software is no exception. For many businesses here in Czechia, especially small and medium-sized enterprises (SMEs), the leap from the familiar linear model to a circular one can seem pretty intimidating. This isn't just about installing a new program. It's about fundamentally rethinking how you operate, getting your team on board with new processes, and embracing a completely different mindset.

Most of the time, the worries boil down to three things: the upfront cost, whether the team has the right digital skills, and shaking off decades of linear "take-make-waste" thinking. These are genuine concerns, and they aren't small. But with a bit of strategy, they are far from insurmountable. In fact, tackling them is the key to unlocking a more resilient and profitable business.

Let’s dive into each of these hurdles and find some practical ways to clear them.

Addressing The Initial Investment Cost

That initial price tag can look like a roadblock, particularly when you're running an SME and keeping a close eye on the budget. But it’s a mistake to see circular economy software solutions as just another expense. Think of it as an investment—one that pays dividends in efficiency, reduces future risks, and gives you a real edge over the competition. The trick is to be smart about how you manage the financial side of things.

The good news is, you don't have to go it alone. There's a lot of support out there to soften the financial blow:

- Government Grants and Subsidies: Keep an eye out for national and EU-level programmes. Many are specifically designed to fund green and digital transitions, helping SMEs adopt new sustainable technologies.

- Phased Implementation: Don't try to boil the ocean. Start small. Pick one clear pain point—like tracking waste on a single production line—and launch a pilot project. This lets you show a quick return and build a solid case for expanding later.

- Subscription-Based Models (SaaS): Many software providers now offer a "Software as a Service" (SaaS) model. Instead of a massive one-off payment, you pay a more manageable monthly or annual fee. This is much kinder to your cash flow.

Bridging The Digital Skills Gap

Rolling out new software often shines a light on skills gaps you didn't even know your team had. This is a common story across almost every industry. Reports on Czechia’s move towards a circular economy have highlighted that many SMEs struggle simply because they aren't aware of the technology and financing options available. It’s clear that specialised training is needed to make the most of these new digital tools. If you're curious about the specifics, you can learn more about how Czech policy supports this digital transition.

A successful software implementation is as much about people as it is about technology. Investing in your team's skills is non-negotiable for long-term success.

The best approach is to be proactive. Talk to your software provider about setting up training sessions tailored to your team's needs. Look for enthusiastic employees who can become your internal "champions"—let them dive deep into the system so they can help their colleagues. This not only gets everyone up to speed faster but also creates a sense of ownership and excitement around the new system.

Cultivating A Circular Culture

This might just be the biggest challenge of all: changing the company culture. For generations, business has been built on a "take-make-waste" foundation. It’s a habit. Moving to a circular mindset means everyone, from the person on the warehouse floor to the CEO, has to start thinking in loops instead of straight lines. You can't just send out a memo and expect this to happen; it has to be nurtured.

Start by being crystal clear about the "why." Explain how these changes will strengthen the business, open up new opportunities, and contribute to a healthier planet. When your early pilot projects start showing results, celebrate those small wins! It builds momentum and shows people the tangible benefits. By getting your employees involved and showing them how their new way of working makes a real difference, you can turn that initial resistance into genuine enthusiasm. Before you know it, you'll have built a culture where sustainability and resourcefulness are just part of your company's DNA.

How to Choose the Right Circularity Platform

Picking the perfect software to bring your circular economy goals to life can feel like a huge task. But with the right approach, it becomes a clear, manageable process. This isn't just about buying another piece of IT; it’s about finding a strategic partner that will make your business more resilient and set you up for future growth. A thoughtful evaluation is the key to making sure the platform you choose is a perfect fit.

The selection process is surprisingly similar to choosing a new enterprise resource planning system. In fact, guides like How to Choose an ERP System can be incredibly helpful. Both decisions demand a serious look at your day-to-day operations, your long-term vision, and how well new tech will play with your existing systems.

Define Your Core Needs and Objectives

Before you even glance at a demo, you need to know exactly what you’re trying to accomplish. Is your main goal to slash packaging waste? Or maybe you want to improve your product take-back programmes or track the recycled content in your supply chain? Each objective calls for different software features.

Start by mapping out how materials flow through your business and pinpointing your biggest headaches and opportunities. This simple audit creates a clear checklist of requirements you can use to vet potential vendors. Without that clarity, it's easy to get wowed by flashy features that don’t actually solve your problems.

Evaluate Key Technical Criteria

Once you know what you need, you can start digging into the technical side of things. Not all circular economy software solutions are built the same, and the best one for you really depends on your specific situation.

Here are the essential areas to investigate:

- Scalability: Can the software grow with you? A platform that’s great for a small pilot project might crumble when you try to roll it out across multiple product lines. Ask vendors straight up how their system handles expansion.

- Integration Capabilities: Your circularity software can't be an island. It needs to talk to your other systems, like your ERP and supply chain tools, without a hitch. Poor integration leads to data errors and manual work, which defeats the whole purpose.

- Industry Specialisation: A platform built for the fast-fashion industry will look very different from one designed for electronics manufacturing. Look for a provider who has real experience and success stories in your specific field.

- Data Security and Compliance: This software will be handling sensitive company data. Take a close look at the vendor’s security protocols, data encryption, and how they comply with data protection laws. Strong sustainability data management is vital for keeping your information safe and accurate. For more on this, check out our guide on sustainability data management software.

Align with National Strategic Goals

For any business operating in Czechia, making sure your choice aligns with national goals is a smart move. The 'Circular Czechia 2040' strategy shows a clear, long-term government commitment to cutting down on material use and encouraging the use of secondary raw materials through digitalisation.

Choosing a platform that helps you meet these goals—especially with material tracking and resource efficiency—doesn't just prepare you for future regulations. It could also open the door to government incentives and funding for green projects.

Right now, the circular material use rate in the Czech Republic is around 8.3%, which is below the EU average of almost 12%. This gap is a massive opportunity for businesses to step up and lead the charge by adopting powerful digital tools. You can learn more about the national strategy from the OECD's report on Czechia's circular economy framework. A forward-thinking software choice will position your company as a central player in this nationwide shift.

Frequently Asked Questions

It’s completely normal to have questions when you’re looking at bringing circular economy software into your business. Especially in Czechia, where many are just starting to see how these tools can really change things up. We’ve put together some straightforward answers to the questions we hear most often from business leaders. The idea is to give you clear, practical advice so you can move forward with confidence.

We’ve laid out the answers to follow the typical journey you might take—from a small business owner wondering where to even start, to bigger questions about how this software fits with what you already have and how it helps with regulations. Think of this as your go-to guide for clearing up any confusion.

What Is The First Step My Small Business Should Take To Implement Circular Economy Software?

For any small business in Czechia, the absolute best place to start is with a simple resource audit. Before you even think about software, take a look around your operation. Map out where your materials come in, where your waste goes out, and what happens to your products once they leave your hands. This simple “waste and resource map” will immediately show you where the biggest opportunities are hiding.

Once you’ve pinpointed a key area—maybe it’s cutting down on packaging waste or getting a better handle on product returns—you can then look for a specific, affordable software solution that tackles just that problem. Starting small with a focused pilot project is a great way to prove the return on investment (ROI) and get your team comfortable with the process before you dive into a larger, all-encompassing platform.

It’s a classic mistake to try and fix everything all at once. A small, successful project builds real momentum and gets people on board far more effectively than some grand plan that never quite gets off the ground.

And don't forget to look into national and EU grants. There are funds specifically set up to help SMEs with their green and digital transitions, which can make that first investment a lot easier to manage.

Can Circular Economy Software Integrate With My Existing ERP System?

Yes, and honestly, it should. Good circular economy software is designed to play nicely with the systems you already use. Most of the top platforms are built with APIs (Application Programming Interfaces) that let them connect and share data with your existing enterprise systems, whether that’s SAP, Oracle, or another ERP or supply chain tool.

This connection is crucial. It ensures everyone is working from the same set of data. For instance, information about raw materials from your ERP can flow directly into the circularity software to track its entire lifecycle. Then, data on recycled materials can flow back into your ERP, keeping your inventory numbers accurate.

This two-way street for data stops information from getting trapped in separate systems and cuts out the tedious, error-prone job of entering everything by hand. When you’re talking to potential software providers, make sure to ask them directly about their integration capabilities. You need to know it will slot neatly into your current tech setup.

How Does This Software Help With Legal Compliance And Reporting?

This is where the software becomes a massive help. It’s a powerful tool for navigating the maze of environmental regulations, like the EU Green Deal and the upcoming Digital Product Passport requirements. These platforms almost always have dedicated compliance modules that automate the heavy lifting of data collection and reporting.

They can track where your materials came from, calculate your carbon footprint, and keep an eye on waste streams to make sure you’re meeting all the legal standards. Instead of spending weeks pulling together data for a regulatory report, the software can generate it in a matter of minutes. This drastically reduces mistakes and frees up your team for more important work.

This helps your business in a few key ways:

- Avoid Fines: By making sure your data is accurate and submitted on time.

- Stay Ahead of Legislation: The software is usually updated to keep up with new laws, helping you prepare for what’s next.

- Prove Sustainability Credentials: It gives you the verifiable data you need to satisfy investors, customers, and regulators.

In short, it turns compliance from a headache and an administrative burden into a streamlined, strategic part of your business.

Is Software For Product-Based Businesses Different From Service-Based Ones?

Absolutely. The end goal—eliminating waste—is the same, but how you get there is very different. The day-to-day focus of a manufacturer is worlds away from a company that leases out equipment, so the software has to be tailored accordingly.

For product-based businesses, like manufacturers or retailers, the software is all about managing physical resources. The key features you’ll see are things like:

- Material traceability

- Lifecycle assessments

- Reverse logistics for handling returns and recycling

On the other hand, for service-based businesses that use a "product-as-a-service" (PaaS) model, the software is more focused on asset management. It’s all about tracking an asset’s location, its performance, and its maintenance schedule to get the most out of its life. The main objective is to make sure the asset is recovered, refurbished, and put back into use, not thrown away.

Here’s a simple way to think about it: for a product company, the software tracks the material. For a service company, it tracks the asset that holds the material. The right software will always align with your specific way of doing business.

Ready to transform your supply chain and turn sustainability into a competitive advantage? Carbonpunk offers an AI-driven platform to automate your emissions tracking, optimise logistics, and generate audit-ready reports with over 95% accuracy. Take control of your carbon footprint today.