Carbon Impact of Shipping and Logistics Explained

Karel Maly

July 14, 2025

Every single product we buy has a story, and part of that story is an invisible environmental cost—a kind of 'carbon backpack' it picks up along its journey from creation to your doorstep. This is the carbon impact of shipping and logistics, the massive, often-overlooked footprint of our global supply chain, which is responsible for a staggering 3% of the world's total emissions.

The Hidden Environmental Cost of Global Trade

It helps to think of the global supply chain as the planet's circulatory system. It’s a vast, intricate network of container ships, freight trains, cargo planes, and delivery trucks that keeps commerce flowing. While this system is the engine of modern life, it runs on enormous amounts of fossil fuels, pumping significant greenhouse gases into our atmosphere with every shipment.

The carbon impact isn't just one single event. It’s the sum of all parts. It starts with the fuel burned by a colossal container ship crossing the Pacific, continues with the train carrying those goods inland, and ends with the delivery van winding its way through your neighbourhood. Each leg of the journey adds another layer to the product's total environmental cost.

More Than Just Transport

While giant ships and long-haul trucks are the most obvious culprits, the carbon footprint of logistics goes much deeper. It includes a whole host of activities that, while less visible, add up in a big way.

- Warehousing and Storage: Think about the massive distribution centres. They’re running 24/7, consuming huge amounts of electricity for lighting, climate control, and the machinery that sorts and moves goods.

- Packaging: From the cardboard boxes to the plastic wrap and foam inserts, manufacturing and disposing of these materials generates significant emissions and waste.

- Reverse Logistics: The journey doesn't always end at the customer's door. Handling returns is a surprisingly carbon-heavy process, responsible for up to 24 million metric tonnes of CO₂ emissions each year as products are shipped back, inspected, and often repackaged or discarded.

A returned product’s journey back through the supply chain can add another 30% to the carbon footprint of its original delivery. This "reverse logistics" loop is a secondary, often hidden, source of emissions that businesses are only now starting to get a handle on.

A Problem of Scale and Complexity

Figuring out how to tackle this problem can feel overwhelming. The sheer scale is mind-boggling—millions of packages, moved by thousands of different carriers, across countless routes, every single day. Trying to pin down a precise carbon footprint for any one item in that complex web is a real challenge.

That's what this guide is for. We're going to break down this complex issue into manageable pieces. We'll look at exactly how this footprint is measured, pinpoint the biggest drivers behind the emissions, and lay out clear, practical strategies your business can use. By turning abstract data into real-world insights, you can build a smarter, more sustainable logistics network—and turn what seems like an environmental burden into a real competitive edge.

How to Measure Your Logistics Carbon Footprint

If you want to shrink the carbon impact of your shipping and logistics, you first need to know exactly how big it is. After all, you can't manage what you don’t measure. This isn't about vague ideas; it's about getting into the details of calculation, but trust me, it’s less intimidating than it sounds.

The gold standard for this is the Greenhouse Gas (GHG) Protocol, which neatly organises emissions into three categories, or "Scopes." Getting your head around these Scopes is the first real step toward taking control of your company's carbon footprint.

Demystifying the Three Scopes of Emissions

Imagine your business operations as a series of concentric circles. Each circle shows a different level of control you have over the emissions being produced.

-

Scope 1 Emissions: This is the bullseye. It’s the emissions your company generates directly. Think of the fuel burned by your own fleet of delivery trucks or the natural gas used to heat your warehouse. These are the sources you can influence most immediately.

-

Scope 2 Emissions: The next circle out covers indirect emissions from the energy you buy. This is mainly the electricity you purchase from the grid to run your offices, power your distribution centres, and keep the conveyor belts moving. You aren't burning the fuel yourself, but your consumption is the reason it’s being burned.

-

Scope 3 Emissions: This is the big one—the outermost circle and often the most complicated. It includes all other indirect emissions happening up and down your company’s value chain. For anyone in logistics, this is where the real action is.

For most companies, Scope 3 emissions are the elephant in the room, often making up over 75% of their entire carbon footprint. This bucket includes all the third-party carriers you hire—the ocean freighters, air cargo planes, and road haulage partners moving your goods across the globe.

Measuring Scope 3 is tough, no doubt. It means chasing down data from partners well outside your direct control. But it's also where you'll find the biggest opportunities to make a difference. If you ignore it, you’re only seeing a sliver of your true environmental impact.

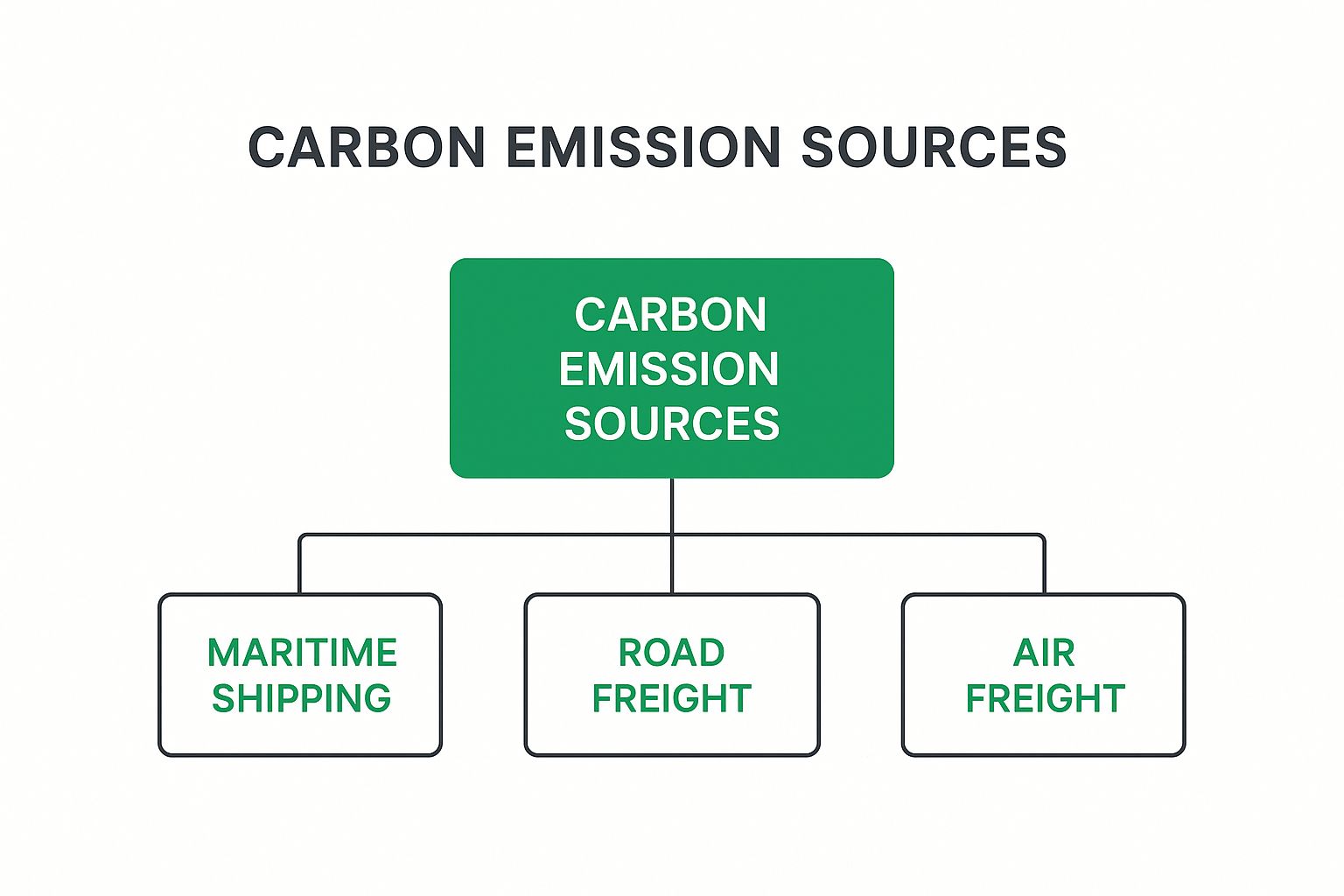

This visual helps break down the main sources of carbon emissions you’ll find across the logistics sector.

As you can see, emissions come from various transport modes, and each one plays a different role in shaping a company's overall Scope 3 footprint.

The following table highlights the primary activities in logistics and the greenhouse gases they typically produce.

Key Carbon Emission Sources in Logistics

| Logistics Activity | Primary Greenhouse Gas | Main Contributing Factors |

|---|---|---|

| Road Freight | Carbon Dioxide (CO₂) | Fuel combustion in diesel and petrol trucks. |

| Ocean Freight | CO₂, Sulphur Oxides (SOx) | Heavy fuel oil combustion in container ships and tankers. |

| Air Freight | CO₂, Nitrogen Oxides (NOx) | Jet fuel combustion at high altitudes. |

| Rail Freight | CO₂ | Diesel-electric locomotive operation or electricity generation. |

| Warehousing | CO₂ | Electricity for lighting, heating, cooling, and equipment. |

This breakdown shows that while CO₂ is the most common culprit, other gases also contribute significantly depending on the specific activity.

From Theory to Practical Measurement

So, the GHG Protocol tells you what to measure, but how do you actually do it? That’s where the Global Logistics Emissions Council (GLEC) Framework comes in. It’s the globally accepted playbook for calculating and reporting GHG emissions from logistics. It gives everyone a standard method for measuring emissions across road, rail, air, and sea, which creates a level playing field for reporting.

To get started, your business needs to pull together a few key data points for every shipment:

- Mode of Transport: Did it go by truck, train, plane, or ship?

- Distance Travelled: How many kilometres did it cover from A to B?

- Weight and Volume: What was the actual or volumetric weight of the cargo?

This data is then plugged into formulas using standardised emission factors to calculate the total CO₂ equivalent (CO₂e) for each shipment. The good news is that many modern logistics providers can now supply this information directly, making things a lot easier than they used to be. For a deeper dive into this process, our complete guide to carbon footprint tracking in logistics breaks down the steps in more detail.

To get a truly accurate measurement, you’ll want to look at technology that can automate data collection and analysis. Exploring leading supply chain visibility tools can be a game-changer for automatically gathering this crucial shipment data. Once you establish a solid baseline, you can finally start pinpointing hotspots, setting realistic reduction targets, and making smarter, more sustainable decisions. This first measurement phase is the foundation for any carbon reduction strategy that actually works.

What Drives Emissions in Your Supply Chain

If you want to meaningfully reduce the carbon impact of shipping and logistics, you first need to understand what's actually fuelling the fire. It helps to think of your supply chain like a car engine; some parts just naturally work harder and burn more fuel than others. The secret to making it run cleaner is figuring out which parts those are.

The emissions coming from your logistics network aren’t just happening by chance. They're the direct outcome of very specific operational decisions. Four main factors—let's call them the ‘big four’—are behind the vast majority of your carbon footprint. Getting a real feel for how they interact is the first step toward making smarter, greener choices.

The Big Four Emissions Drivers

Pinpointing where your emissions are coming from lets you shift from abstract worry to concrete action. Every single shipment you manage is a unique blend of these four elements, and just tweaking one of them can have a massive knock-on effect on its total carbon output.

- Transport Mode: This is the big one. Whether you move your goods by plane, ship, train, or truck has an enormous impact on your footprint.

- Distance: Simple and straightforward. The farther a product travels, the more fuel it burns and the more emissions it creates.

- Weight: Heavier, bulkier shipments demand more energy to move, no matter which mode of transport you use.

- Efficiency: This is all about how well you use the space you have. One fully loaded truck is far more carbon-efficient per item than two half-empty ones making the exact same trip.

Think about it: choosing to send a package by air instead of rail can increase its carbon footprint by more than 40 times. That single decision powerfully illustrates just how vital mode selection is.

Your logistics carbon profile is defined by the relationship between these four drivers. A heavy shipment travelling a short distance in a full truck might have a lower footprint than a lightweight package flown clear across the country. Mastering this balancing act is the very essence of sustainable logistics.

Transport Mode: The Heavy Hitter

While all four drivers are important, your choice of transport mode consistently has the most dramatic impact on emissions. Different modes have vastly different energy requirements and, as a result, produce wildly different amounts of greenhouse gases per tonne-kilometre (the industry's yardstick for comparing freight).

The data clearly shows that road transport is a massive contributor to emissions, making it a critical area for any business to focus on optimising.

Let's break it down with a quick comparison:

- Air Freight: The fastest way to get something from A to B, but also by far the most carbon-intensive. It's best kept for only the most urgent, high-value, or perishable goods.

- Road Freight: Hugely flexible and absolutely essential for that final mile, but its emissions can add up quickly, particularly on long-haul journeys.

- Rail Freight: A much more efficient choice than road for moving large volumes over long distances on land. It can slash emissions by up to 75% compared to trucking.

- Ocean Freight: The undisputed champion of carbon efficiency for global trade. It can move immense volumes with the lowest emissions per tonne-kilometre, though it's also the slowest option.

Accurately tracking these factors across a complex web of different carriers and transport modes is one of the central challenges in logistics sustainability. Having a solid grasp of carbon accounting for supply chains explained in more detail is a foundational step towards building a system that can actually measure what matters.

Actionable Strategies for Greener Logistics

Knowing your numbers is the starting line. But now it’s time to move from theory to action with practical strategies that can genuinely shrink your logistics carbon footprint. Tackling the carbon impact of shipping and logistics isn't about one magic bullet; it's about a combination of smarter operations, new technology, and better partnerships.

And here's the best part: these strategies aren't just about being green. They almost always lead to better efficiency, lower running costs, and a supply chain that's far more resilient. Even small adjustments can make a big difference in hitting your sustainability targets.

Optimise Your Network and Loads

One of the most effective ways to slash emissions is to get smarter with the network you already have. It's about using your existing assets more intelligently. Often, the most significant wins don't come from massive investments but from small, data-driven tweaks to how you operate.

The two most important areas to focus on are route planning and load consolidation.

- Route Optimisation: This means using software to find the most fuel-efficient delivery paths. It's much more than just finding the shortest A-to-B route; it considers real-world factors like traffic, vehicle capacity, and delivery times to cut down on mileage and wasteful idling. Using powerful route optimisation algorithms is a game-changer for streamlining operations and slashing fuel use, which directly lowers your carbon output.

- Load Consolidation: Simply put, stop shipping air. This is the practice of filling your trucks. By grouping smaller shipments into a single full truckload (FTL), you dramatically boost the carbon efficiency for every item you move. This might mean working with other local businesses to share truck space or tweaking your shipping schedules to build up bigger loads before they go out.

Think about it: a mid-sized e-commerce company could potentially cut its last-mile emissions by as much as 30% just by bringing in route optimisation software. That single change saves money on fuel, cuts emissions, and often gets packages to customers faster.

Embrace a Strategic Modal Shift

We've touched on this already, but it bears repeating: your choice of transport is the biggest lever you can pull to change your emissions. A modal shift is the conscious decision to move freight from a high-carbon mode (like air) to a lower-carbon one (like rail or sea) whenever it makes sense.

Of course, this is always a trade-off between speed, cost, and carbon impact.

| From (High-Carbon) | To (Low-Carbon) | Potential CO₂ Reduction | Best For |

|---|---|---|---|

| Air Freight | Sea Freight | Up to 95% | Non-urgent, large volume international shipments. |

| Long-Haul Truck | Rail Freight | Up to 75% | High-volume, cross-country domestic shipments. |

| Delivery Van | Cargo Bike | Up to 90% | Dense urban, last-mile deliveries. |

While switching from air to sea freight adds time to the journey, the environmental payoff is enormous. For many businesses, the answer is a hybrid approach—using faster, high-carbon options only for truly time-sensitive products and shifting everything else to greener, more economical alternatives. You can dig deeper into how to reduce supply chain carbon emissions with expert strategies in our dedicated guide.

Adopt Greener Technology and Fuels

Innovation is one of our best allies in the push for sustainable logistics. While some technologies are still on the horizon, many are here today, ready to make an immediate impact.

The key areas for tech adoption are:

- Electric Vehicles (EVs): For last-mile and regional deliveries, EVs are a perfect fit, producing zero tailpipe emissions. As batteries get better and charging points become more common, their range and ability to handle heavier loads will only increase.

- Alternative Fuels: For the big stuff—long-haul trucking and ocean shipping—full electrification is still a challenge. Here, alternatives like biofuels, renewable natural gas (RNG), and green hydrogen are becoming real, viable replacements for diesel and bunker fuel.

- Telematics and AI: These systems act like a fitness tracker for your fleet. They give you real-time data on vehicle performance, driver habits, and fuel burn. By analysing this information, you can spot inefficiencies, like too much idling or poor routing, and fix them on the fly.

Collaboration is the secret weapon here. By partnering with carriers who have already invested in electric trucks or low-carbon fuels, you can piggyback on their sustainability efforts. This reduces your own Scope 3 emissions without you having to make the huge capital investment yourself.

This is especially critical in places like Czechia, which faces unique logistical hurdles. As a landlocked country, its logistics sector leans heavily on road freight. The EU’s Effort Sharing Regulation demands that Czechia cut transport emissions by 14% by 2030 (from 2005 levels), but progress has been slow. This creates a huge opportunity for Czech logistics companies to lead the way by adopting these greener technologies to meet both national and EU goals. You can read more about the detailed pathways to decarbonise the Czech Republic in this in-depth analysis.

The Future of Sustainable Shipping

The journey toward greener logistics is picking up serious speed. The strategies we have today are merely the first step; a new wave of technology and progressive policy is poised to completely reshape the carbon impact of shipping and logistics. This isn't some far-off, futuristic dream. It's happening right now, built on tangible innovations and evolving rules.

For any business that wants to stay competitive, getting a handle on these future trends is about more than just being environmentally responsible. It's about getting ready for the next operational reality. The companies that see these changes coming will be the ones that thrive.

Emerging Green Technologies

The next decade promises a monumental shift in the tools and fuels powering our supply chains. We’re already seeing electric vans handle last-mile deliveries, but the real game-changer lies in technologies built for the industry’s toughest challenges: long-haul trucking and ocean freight.

These key innovations are leading the charge:

- Autonomous and Electric Trucks: Imagine fleets of self-driving, electric trucks gliding down motorways, their routes optimised by AI to travel during off-peak hours for peak efficiency. While full autonomy is still on the horizon, sophisticated driver-assistance systems are already making a dent in fuel consumption today.

- Green Hydrogen and Ammonia: For the colossal container ships that cross our oceans, batteries simply aren't a practical option. That's why the industry is betting heavily on alternative fuels like green hydrogen and ammonia. These can be produced using renewable energy and, crucially, they burn without releasing carbon.

- AI-Powered Predictive Platforms: What if you had a system that could see into the future? AI platforms are evolving from simple route planners to powerful tools that can forecast emissions across an entire supply chain. By analysing weather patterns, port congestion, and carrier performance, they can suggest smart adjustments before a shipment even leaves the warehouse.

The most profound shift here is moving from reactive measurement to predictive management. Instead of just tracking emissions after a journey is complete, future systems will forecast and prevent them. This turns carbon management from a simple reporting task into a powerful strategic planning tool.

The Evolving Regulatory Landscape

Technology alone isn’t enough to drive this massive transition; it needs a firm push from policy. Governments, especially in Europe, are building a regulatory framework that makes sustainability non-negotiable. These new rules are designed to fast-track the move to greener logistics and hold businesses accountable for their emissions.

The most significant development is the European Union's 'Fit for 55' package. This is a comprehensive set of laws aimed at cutting the EU’s greenhouse gas emissions by at least 55% by 2030.

What 'Fit for 55' Means for Logistics

This sweeping policy has direct, immediate consequences for any company moving goods within or through Europe. It’s not an abstract target but a set of concrete rules with very real financial teeth.

Here’s what it means in practice for the logistics sector:

- FuelEU Maritime Initiative: This regulation forces ships calling at EU ports to progressively lower the greenhouse gas intensity of the fuel they use. It’s a powerful incentive for shipping lines to finally invest in those alternative fuels like green hydrogen.

- Inclusion in the Emissions Trading System (ETS): For the first time ever, maritime shipping emissions are part of the EU's carbon market. This means shipping companies must now purchase allowances for every tonne of CO₂ they emit on voyages connected to the EU, making pollution a direct and ever-increasing cost.

- Stricter CO₂ Standards for Trucks: New, more ambitious emission reduction targets are being rolled out for heavy-duty vehicles. This puts pressure on manufacturers to ramp up the production of zero-emission trucks.

Together, these regulations build a clear business case for decarbonisation. As the costs of high-carbon operations continue to climb, the economic advantage will decisively shift to businesses that have already embraced sustainable practices. This prepares logistics operators not just for compliance, but for a competitive edge where the carbon impact of shipping and logistics is a core business concern.

Taking Action for a Greener Supply Chain

We’ve walked through how to measure carbon impacts, what drives them, and the strategies available to tackle them. Now, let's put it all into practice. Shifting to a sustainable supply chain isn't just a side project anymore; it's a smart business move that makes you more efficient, saves money in the long run, and resonates with customers who care about the environment.

The first step is always the hardest, but it’s simple: you have to know where you stand. Once you have a clear picture of your logistics footprint, you can start making targeted, meaningful changes. This isn't just a game for the big players, either. Every single business, no matter its size, has a part to play in pushing global trade towards a greener future.

The move to green logistics is really an investment in your company’s resilience. When you shift away from unpredictable fossil fuel costs and outdated, wasteful methods, you’re building a supply chain that’s stronger, more predictable, and better prepared for whatever comes next.

This journey, from just measuring emissions to actually doing something about them, is what separates the leaders from the laggards.

Taking Your First Step

The way forward is built on one simple idea: continuous improvement. It means getting smarter with your network design, bringing in cleaner technologies, and working hand-in-hand with partners who are on the same page. If you're looking for financial backing to support these kinds of emission-reduction projects, the Greenhouse Gas Reduction Fund is an excellent resource to explore.

Remember, every route you optimise, every shipment you consolidate, and every time you choose rail over air freight, it’s a win. These aren't just small tweaks; they are real, measurable steps toward cleaning up your operations and helping the planet. The time for just talking about it is over. It’s time to take that first critical step and start building a supply chain that’s not only greener but also more efficient for the years to come.

Frequently Asked Questions

As you dig into the world of logistics emissions, a few common questions tend to pop up. Let's tackle some of the most frequent ones to give you clear, practical answers you can use right away.

How Can a Small Business Start Measuring Its Logistics Carbon Footprint?

Getting started doesn't have to be complicated. The best first step for a small business is usually to use a logistics carbon calculator, most of which are based on the solid principles of the GLEC Framework. Just start by gathering some basic data for a specific timeframe, like a single quarter.

You'll need to pull together a few key details for your shipments:

- The mode of transport you used (road, rail, air, sea).

- The total distance each shipment travelled.

- The weight of the goods you shipped.

To avoid feeling overwhelmed, focus on your most common shipping routes first. This will give you a solid baseline to work from. It's also worth noting that many modern freight forwarders and logistics platforms now build this data right into their services, which can make collecting it much, much easier.

What Is the Single Most Effective Way to Reduce Shipping Emissions?

If you're looking for the one change that delivers the biggest bang for your buck, it's almost always a modal shift. This simply means moving your freight from a high-carbon mode of transport to a lower-carbon one whenever it makes sense for your business.

Shifting cargo from air freight to ocean freight can slash emissions by over 90%. Similarly, moving goods from long-haul lorries to rail can cut emissions by 75% or more.

Of course, this isn't always possible—longer transit times can be a deal-breaker. But when you can make it work, a modal shift is the most powerful lever you have for shrinking your logistics carbon footprint.

Are Electric Lorries a Viable Option for Long-Haul Freight in Europe Today?

Electric lorries are making serious headway, especially for last-mile and regional deliveries in and around cities. They're quiet and have zero tailpipe emissions, which makes them a perfect fit for urban logistics.

For long-haul journeys across Europe, however, they still face some big hurdles. The main challenges are limited battery range, less room for cargo because of the heavy batteries, and a real shortage of high-speed charging stations along major transport routes.

So, for now, diesel remains the king of long-haul logistics. But keep an eye on this space—the technology is evolving fast. Hydrogen fuel cell lorries and next-generation electric models with better range are set to become much more common and competitive in the next few years.

Ready to move beyond estimations and take control of your supply chain's carbon footprint? Carbonpunk offers an AI-driven platform that automates the tracking, analysis, and reporting of your logistics emissions with over 95% accuracy. Transform your sustainability goals into measurable results and gain a competitive edge by visiting the Carbonpunk website.