Effective Strategies for Carbon Intensity Reduction in Manufacturing

Karel Maly

October 3, 2025

Reducing carbon intensity in manufacturing isn't just about abstract green goals; it's about making your operations leaner and more efficient. In simple terms, it means lowering the amount of CO₂ you emit for every single unit you produce.

You get there by optimising how you use energy, switching over to cleaner power sources, and fine-tuning your production processes from the ground up. I've seen firsthand how this strategy helps manufacturers cut costs, stay ahead of regulations, and carve out a serious competitive advantage.

Why Your Manufacturing Business Needs to Act on Carbon Intensity

Let's cut through the jargon. Carbon intensity is more than just an environmental metric; it’s a direct reflection of your operational efficiency and how prepared you are for the future. Thinking of it as just a "green thing" is a huge mistake. This is about building a business that's more resilient, cost-effective, and competitive.

For manufacturers, particularly those navigating strict regulatory frameworks like the EU's Emissions Trading System (ETS), this pressure is no longer a distant threat. It’s here, and it's hitting the bottom line. Ignoring it means you're not just risking financial penalties—you're letting competitors who have already turned sustainability into a strength get ahead.

The Pressure Is Mounting

It's not just coming from regulators, either. The market itself is shifting. Customers, whether they're B2B partners or end consumers, are demanding more transparency and sustainability from every link in the supply chain. A high carbon intensity can quickly become a major liability, putting contracts at risk and tarnishing your brand's reputation.

This is a particularly sharp challenge—and a unique opportunity—within the Czech industrial landscape. The sector has made some incredible strides, but it's still a major focus area for decarbonisation efforts.

The Czech Republic's industrial sector slashed its emissions by 54% between 1990 and 2017. Even so, the sector still accounted for 28% of the nation's total greenhouse gas emissions as of 2017. This really highlights the ongoing need for a focused push on carbon intensity reduction.

This data drives home the urgency. This isn’t just about ticking a compliance box; it's about future-proofing your business in a market that increasingly rewards efficiency and environmental stewardship.

Turning Carbon Reduction into Competitive Advantage

Smart carbon management delivers real, tangible benefits to your business, and the most immediate impact is on your energy bills. Every kilowatt-hour you don't use is money straight back into your pocket. Simple as that.

The table below breaks down the main reasons why manufacturers are getting serious about this. These are the key drivers I see pushing companies to act, moving from external pressures to internal gains.

Key Drivers for Reducing Carbon Intensity

| Driver | Description | Impact on Manufacturing |

|---|---|---|

| Cost Savings | Direct reduction in operational expenditures through lower energy consumption and waste. | Improves profit margins and frees up capital for other investments. |

| Regulatory Compliance | Avoiding penalties and staying ahead of increasingly strict emissions standards. | Reduces financial risk and builds a positive relationship with regulatory bodies. |

| Enhanced Brand Reputation | Demonstrating a clear commitment to sustainability. | Attracts environmentally conscious customers, talent, and investors. |

| Supply Chain Resilience | Efficient operations are less vulnerable to energy price shocks and market instability. | Creates a more robust, predictable, and reliable business model. |

Ultimately, the motivation to reduce carbon intensity is a powerful mix of risk mitigation and strategic opportunity.

It's also worth noting that you don't have to go it alone. Financial incentives, like those from the Greenhouse Gas Reduction Fund, can be a powerful catalyst for accelerating your decarbonisation journey. These programmes can help take the sting out of the initial investment in cleaner technologies, making the switch far more manageable.

To get a better sense of where your operations stand, it's helpful to see how you stack up against others. You can explore these insightful https://www.carbonpunk.ai/en/blog/carbon-footprint-benchmarks-by-industry-key-insights in our detailed guide.

In the end, taking a proactive approach to carbon intensity reduction in manufacturing isn't an expense. It's a strategic investment in your company's long-term profitability and its leadership position in the market.

How to Measure Your Carbon Intensity Baseline

Before you can even think about reducing your carbon intensity, you have to know where you stand. It’s a simple truth: you can't improve what you don't measure. The first, non-negotiable step is to establish an accurate baseline, which means rolling up your sleeves and conducting a forensic audit of your energy use and production output.

This isn't just about ticking an environmental box. It’s about creating a clear starting line so you know exactly how far you need to go and can track your progress meaningfully. Without this solid foundation, any reduction targets you set are just shots in the dark. A good baseline helps you pinpoint your biggest emission sources, letting you focus your efforts where they'll make a real difference.

Starting with Scope 1 and Scope 2 Emissions

The best place to begin is with the low-hanging fruit: your Scope 1 and Scope 2 emissions. These are the most direct and controllable sources, and you probably already have all the data you need tucked away in your records.

-

Scope 1 Emissions: Think of these as the emissions happening right under your roof. They come from sources you own or control, like the fuel burned in your boilers, furnaces, or company vehicles. All the data you need is sitting in your fuel purchase records and utility bills.

-

Scope 2 Emissions: These are the indirect emissions from the energy you buy. We're talking about the electricity, steam, heating, and cooling that power your facility. Your electricity bills are the key here—you just need to know how many kilowatt-hours (kWh) you used over a specific period, like the last financial year.

Honestly, getting this information is often easier than it seems. Your accounts department is already tracking these expenses. The trick is to look at those bills not just as costs, but as data points—litres of diesel, cubic metres of natural gas, total kWh of electricity.

A detailed baseline isn't just an environmental exercise; it's a powerful operational analysis tool. It shines a light on inefficiencies that are already hitting your bottom line, turning a sustainability task into a genuine cost-saving project.

Once you’ve got the raw numbers, you'll use standard emission factors to convert your energy consumption into a carbon dioxide equivalent (CO2e). Various government and international bodies provide these factors, which are tailored to different fuels and the specific energy grid in your region. This conversion is what creates a standardised metric you can actually work with.

Demystifying the Carbon Intensity Calculation

With your total emissions data in hand, you’re ready to calculate your carbon intensity. This is the metric that ties your emissions directly to your output, giving you a powerful measure of efficiency. The formula itself is quite simple:

Carbon Intensity = Total CO2e Emissions / Total Production Units

The "Total Production Units" part needs to be a metric that genuinely reflects what your business does. It could be anything from:

- The number of widgets you produced.

- Tonnes of steel you manufactured.

- Square metres of fabric you finished.

The goal is to get a ratio that shows how much carbon you emit for every unit of value you create. A figure like 2.5 kg CO2e per widget gives you a concrete benchmark. As you start making changes, you can track this number to see if your efforts in carbon intensity reduction in manufacturing are really working. For a closer look at the nuts and bolts, you can learn more about how to optimise your business with carbon intensity tracking in our detailed guide.

Tackling the Challenge of Scope 3

While getting a handle on Scope 1 and 2 is a fantastic start, the elephant in the room for most manufacturers is Scope 3 emissions. These often make up the largest chunk of your total carbon footprint. They cover all the other indirect emissions in your value chain, from the raw materials you buy to the trucks that deliver your finished products.

The image below from the European Parliament really drives home how much manufacturing contributes to national emissions, highlighting why looking beyond your own factory walls is so important.

This data shows that while direct factory emissions are a major focus, the entire industrial ecosystem, including the supply chain, is a critical battleground for decarbonisation.

Measuring Scope 3 is definitely complex, but don't let that intimidate you. You don’t have to boil the ocean all at once. Start with your biggest impact areas, like purchased goods and services or upstream logistics. A great first step is simply to start a conversation with your key suppliers and ask for their emissions data. This initial outreach does more than just get you information—it signals your commitment to sustainability and can inspire positive change throughout your entire supply chain.

Finding Quick Wins in Energy Efficiency

For most manufacturers, energy consumption is the single biggest driver of carbon intensity. That makes it the most logical place to start your reduction journey. The best part? Focusing on energy efficiency delivers a powerful one-two punch: it directly cuts your operational costs while simultaneously shrinking your carbon footprint.

The key is to begin with a solid energy audit to identify the "low-hanging fruit"—those quick fixes that offer the biggest impact with the least upfront investment.

This isn’t just theory; it’s about practical, on-the-ground action. I've seen countless facilities lose a staggering amount of energy through simple, often overlooked issues. Think of it like trying to heat a house with the windows wide open. You're paying for energy that's literally vanishing into thin air.

Uncovering Hidden Energy Drains

One of the most notorious culprits in any plant is a leaky compressed air system. These systems are essential for powering tools and machinery, but even a tiny, pinhole-sized leak can waste thousands of euros in electricity costs over a year. A thorough audit using ultrasonic leak detectors can quickly pinpoint these problems, allowing for fast repairs that often pay for themselves in just a few months.

Another area ripe for quick wins is your machinery maintenance schedule. Instead of waiting for a motor to fail, why not plan upgrades during routine maintenance cycles?

- High-Efficiency Motors: Swapping out an old, standard-efficiency motor for a modern one can cut that specific machine's energy use by up to 15%. Scheduling this during planned downtime means zero disruption to your production.

- Variable Speed Drives (VSDs): For equipment that doesn't need to run at full power all the time—like pumps, fans, and conveyors—installing VSDs is a game-changer. These devices adjust the motor's speed to match real-time demand, stopping you from burning energy when you don't need to.

A proactive approach to maintenance isn't just about preventing breakdowns. It’s a strategic opportunity to embed energy efficiency directly into your operational DNA, making carbon intensity reduction in manufacturing a continuous, integrated process.

Smart controls and sensors offer another layer of immediate savings. Simple timers, motion sensors for lighting in low-traffic areas, and programmable thermostats can automate energy savings without any major capital projects. These small adjustments really do add up over time.

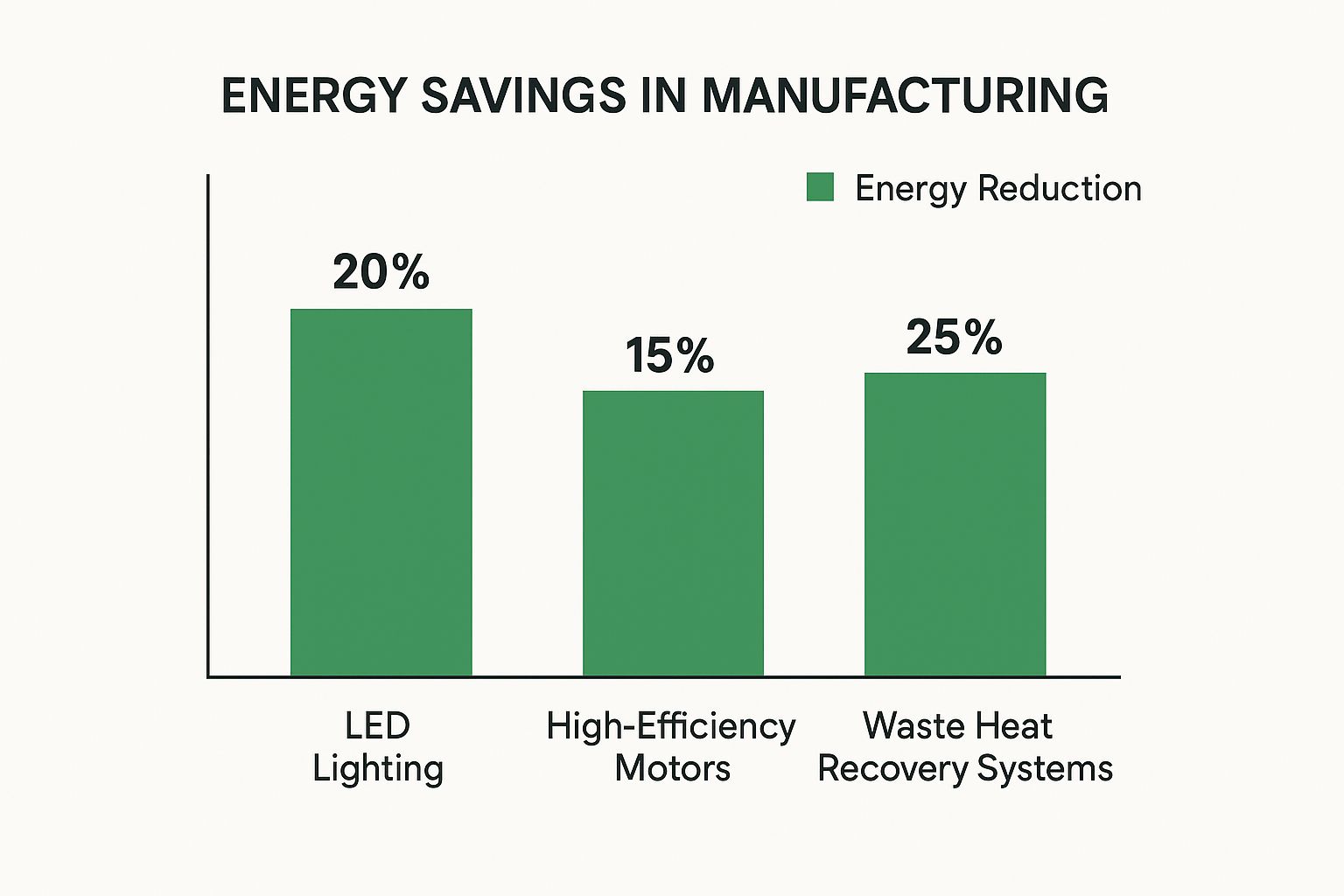

This infographic gives a good sense of the typical energy savings you can expect from several common efficiency upgrades.

As you can see, while lighting and motor upgrades offer solid gains, capturing and reusing waste heat often presents the largest single opportunity for energy reduction.

When deciding where to focus your efforts, it helps to compare the most common initiatives.

High-Impact Energy Efficiency Measures

Here’s a quick look at some popular energy efficiency projects, comparing their potential impact with their typical return on investment for a manufacturing setting.

| Efficiency Measure | Potential Carbon Reduction | Typical Payback Period |

|---|---|---|

| LED Lighting Retrofit | 10-20% (for lighting) | 1-3 years |

| Compressed Air Leak Repair | 5-15% (system-wide) | < 1 year |

| High-Efficiency Motors | 10-15% (per motor) | 2-5 years |

| Waste Heat Recovery | 15-25% (plant-wide) | 3-7 years |

| Variable Speed Drives (VSDs) | 20-50% (for specific equipment) | 1-4 years |

This comparison highlights that even simple, low-cost actions like fixing air leaks can yield surprisingly fast returns and meaningful carbon reductions.

Turning Waste Heat into a Valuable Asset

Many industrial processes, from furnaces and ovens to compressors, generate a tremendous amount of heat as a byproduct. Traditionally, this heat is just vented into the atmosphere—a wasted resource and a source of thermal pollution. With waste heat recovery systems, however, you can capture this exhaust and put it back to work.

Imagine a metalworking facility with a large furnace. Those hot exhaust gases can be channelled through a heat exchanger to pre-heat raw materials, boil water for steam, or even provide space heating for the entire building in winter. This creates a closed-loop system where energy is used multiple times, drastically reducing the need for primary fuel.

Czech industries, particularly in sectors like glass and ceramics manufacturing, have seen great success with these systems. By capturing exhaust heat from their kilns, they've managed to slash their natural gas consumption for drying processes, leading to substantial cost savings and a measurable drop in carbon intensity.

These efficiency strategies are clearly working on a national scale. Overall greenhouse gas emissions in the Czech manufacturing and construction sectors have shown marked reductions in recent years. In fact, the share of these sectors within the country's total emissions declined from 12.6% to 7% over a recent period. This successful push towards lower-carbon operations is often driven by incentives within frameworks like the EU Emissions Trading System (ETS). You can dig into the specifics in this European Parliament briefing on Czech emissions689329_EN.pdf).

By focusing on these high-impact, readily available solutions, you can make immediate and meaningful progress on your decarbonisation goals.

Making the Switch to Cleaner Energy Sources

So, you’ve managed to squeeze every last drop of efficiency out of your current setup. What’s next? The single most powerful move you can make is to fundamentally change the energy you consume.

This isn’t just about tweaking your operations anymore; it’s about transformation. It means moving away from fossil fuels by looking critically at both the electricity you buy and the power you could be generating yourself.

For many manufacturers, the most direct path forward is simply to buy greener electricity. This usually involves switching to a tariff where your supplier guarantees that the power you pull from the grid is matched by generation from renewable sources like wind, solar, or hydro. It's a contractual shift that can slash your Scope 2 emissions almost overnight, without needing any upfront investment in new kit.

Let the Greening Grid Do Some of the Work

The good news is that manufacturers in the Czech Republic already have a helpful tailwind. The national grid has been steadily decarbonising for more than two decades, and that benefits every single business connected to it.

This long-term trend gives a real boost to your own carbon intensity reduction in manufacturing efforts. Think about it: between 2000 and 2023, the carbon intensity of Czech electricity plummeted from around 767 grams of CO2 per kilowatt-hour (gCO2/kWh) down to about 450 gCO2/kWh. That’s a drop of nearly 41%, driven mostly by the shift from coal to nuclear and renewables. You can dig into the data on the Czech power sector's carbon intensity on Statista.

This means your factory's electricity is getting cleaner every year, even if you do nothing at all. But by consciously choosing a green tariff, you accelerate that progress and send a clear signal to the market that there’s strong demand for more renewable generation.

Taking Control with Onsite Generation

Green tariffs are a great start, but generating your own power gives you a far greater degree of control over costs, supply, and your carbon footprint. For any manufacturer with a large, flat roof, onsite solar photovoltaic (PV) systems are becoming an obvious choice. That huge, empty space is perfect for an array that could generate a massive chunk of the electricity you need during daytime operations.

Taking this step brings some serious advantages:

- Lower Energy Bills: Producing your own power insulates you from volatile market prices and makes a real dent in your monthly utility costs.

- Greater Resilience: Onsite generation makes you less dependent on the grid, which can be a lifeline during outages or instability.

- Stronger Brand: A roof full of solar panels is a powerful and very visible statement about your company's commitment to sustainability.

Onsite solar is more than an energy project; it's a long-term investment in operational independence and sustainability. It transforms a passive asset—your roof—into an active contributor to your bottom line and your carbon reduction goals.

If you're considering this path, a buyer's guide to industrial solar panels can offer some vital pointers for planning and implementing a large-scale project.

Tackling the Tough-to-Decarbonise Processes

Let’s be realistic, though. Some industrial processes, especially those needing extreme heat for furnaces or kilns, are incredibly difficult to run on electricity with today's technology. For these stubborn applications, you have to start exploring alternative fuels.

This is where things like biomass or even green hydrogen enter the picture.

| Alternative Fuel | Best Use Case | Key Consideration |

|---|---|---|

| Biomass | High-temperature process heat | You absolutely need a sustainable and reliable local supply of feedstock. |

| Green Hydrogen | Direct fossil fuel replacement | It's currently very expensive and requires a major investment in new infrastructure. |

Switching to these fuels is no simple drop-in replacement. It often demands significant capital to retrofit or replace equipment and build entirely new supply chains. Still, for energy-hungry sectors like cement or steel manufacturing, these alternatives are a critical part of the long-term journey to deep decarbonisation. It requires careful planning, but it's an essential piece of the puzzle if you're serious about reaching net-zero.

Using Technology to Drive Deep Decarbonisation

While sorting out your energy efficiency and switching to cleaner power sources are essential first steps, true innovation is what really sets you apart from the competition. Modern technology gives us a powerful toolkit to fundamentally reshape our carbon footprint, helping us move beyond small tweaks to make deep, lasting changes. This is where a smart investment in technology stops being a cost and starts becoming a cornerstone of operational excellence.

By weaving smart tech into your day-to-day processes, you gain a level of insight and control that was simply unimaginable a decade ago. It allows you to catch energy waste before it happens, fine-tune machinery for peak performance, and even redesign core production methods to eliminate emissions at their very source.

The Power of Real-Time Data and AI

One of the quickest wins from technology is its ability to make the invisible, visible. Across the industry, manufacturers are rolling out networks of Internet of Things (IoT) sensors. These little devices are a game-changer, giving you a constant stream of live data on everything from a single machine’s energy draw to the humidity in a specific corner of the workshop.

Forget waiting for the monthly utility bill to figure out where the energy went. Now you can see exactly which machine is guzzling power, right at this very moment. This granular view means you can act immediately. For instance, an IoT sensor might flag a motor that’s suddenly using 20% more energy than its normal baseline, pointing to a maintenance need long before it breaks down and halts production.

This data gets even smarter when you feed it into Artificial Intelligence (AI) platforms. AI algorithms are brilliant at sifting through mountains of historical and real-time data to spot patterns, predicting when a piece of equipment is likely to fail. This is what we call predictive maintenance, and it’s key to keeping your machinery running at peak efficiency and avoiding the energy waste that comes from poorly performing gear.

Technology transforms carbon management from a reactive, backward-looking exercise into a proactive, data-driven strategy. It empowers you to make smarter decisions in real time, turning operational data into direct carbon and cost savings.

Of course, you need the right tools to manage all this information. If you're looking at your options, our guide to the top 12 carbon tracking software for manufacturing in 2025 breaks down the leading platforms on the market.

Rethinking Core Manufacturing Processes

Beyond just monitoring and optimising, technology lets you completely rethink some of your core industrial processes—especially those that have always relied on fossil fuels. This kind of process innovation is where some of the biggest gains in carbon intensity reduction in manufacturing are being made.

Take high-temperature processes, a massive source of emissions in sectors like metallurgy and ceramics. For decades, the answer was a furnace burning natural gas. Today, we have much cleaner alternatives thanks to process electrification.

- Electric Furnaces: Swapping out old fossil-fuel furnaces for modern electric arc or induction furnaces can slash direct onsite emissions to zero, as long as your electricity comes from a renewable source.

- Industrial Heat Pumps: These are genuinely impressive bits of kit. They can capture waste heat or even ambient heat from the air and amplify it to the high temperatures needed for things like drying or pasteurisation. They are vastly more efficient than old-school boilers and can often cut the energy needed for heating by over 50%.

Let’s look at a real-world example in the textile industry. A typical wet-processing plant is heavily dependent on natural gas boilers to make steam for dyeing and finishing fabrics. By making the switch to industrial heat pumps powered by renewable electricity, that facility can completely decarbonise its heating needs—a huge step towards making a zero-carbon product.

Integrating Circular Economy Principles

Technology is also the engine driving the shift to a circular economy, a model that finally breaks us out of the old "take-make-waste" cycle. The focus here is on designing products to last, to be repaired, and to be recycled at the end of their life. This approach has a massive, positive impact on your total carbon footprint.

Modern design software helps engineers create products that use far less material without compromising on strength. For example, advanced modelling can help refine a component’s geometry to make it 30% lighter. That doesn’t just save on raw materials; it also cuts the energy needed to produce and transport it.

On top of that, technologies like digital twins—which are virtual replicas of a physical product or process—allow you to test and optimise everything in a simulated world. This drastically reduces the need for physical prototypes, saving both materials and energy. By designing products that are easy to take apart and whose parts can be reused or recycled, you cut down on the embodied carbon that comes from mining and processing new materials. It’s this holistic view, powered by technology, that builds a truly resilient, efficient, and future-proof manufacturing business.

Common Questions About Manufacturing Decarbonisation

Taking the first steps toward decarbonisation can feel like a huge task. It’s only natural to have practical questions. I hear the same concerns all the time from manufacturing leaders: what will it cost? How much will it disrupt our operations? Where on earth do we even start?

Let’s tackle those common questions head-on. The idea here is to give you clear, straightforward answers to help you move from simply thinking about this to actually doing something about it.

What Is the Biggest Challenge for a Small Manufacturing Business?

For smaller manufacturers, the single biggest hurdle is almost always finding the upfront cash for new, more efficient equipment. Everyone understands that lower energy bills will save money in the long run, but that initial investment can feel impossible when you're working with tight cash flow.

The best way forward is to start with the low-cost, high-impact wins. These build momentum without breaking the bank.

- Fix Leaky Systems: A proper audit of your compressed air system can uncover leaks that are quietly costing you thousands of euros a year.

- Optimise Maintenance: Simply fine-tuning maintenance schedules for your core machinery ensures it runs at peak efficiency, which stops energy from being wasted.

- Conduct a Basic Audit: A simple energy audit is a fantastic starting point. It will almost certainly reveal quick savings in areas like lighting and insulation.

It's also worth actively looking for government grants and financing programmes. There are a surprising number of initiatives, especially here in the Czech Republic and across the EU, designed specifically to help industrial SMEs pay for their switch to cleaner technologies.

How Do I Reduce Carbon Intensity Without Disrupting Production?

Keeping the lines running is priority number one; no manufacturer can afford unnecessary downtime. The good news is that a smart decarbonisation strategy is designed to work with your existing schedule, not against it.

Many of the foundational improvements can be put in place with little to no hit on your output. Think about upgrading your facility's lighting to energy-efficient LEDs or installing smart sensors—that’s work that can easily be done during off-hours or over a weekend.

The secret to a smooth transition is all in the planning. By lining up major upgrades with your scheduled maintenance shutdowns, you can overhaul your operations without losing a single minute of production time.

When you're tackling bigger projects, like replacing a major piece of machinery, schedule the work for your annual shutdown or do it one production line at a time. The most important thing is to get your production and maintenance teams involved right from the start. Their hands-on knowledge is gold for figuring out the least disruptive times to get things done.

Does Reducing Carbon Intensity Always Mean Higher Costs?

No, absolutely not. This is one of the biggest myths out there, and frankly, the opposite is usually true. Focusing on reducing your carbon intensity almost always leads to direct, measurable cost savings.

Think about it: any initiative focused on energy efficiency—like cutting down on waste or optimising a process—has an immediate and positive impact on your bottom line. Less energy used means lower utility bills. It's that simple.

While some of the more advanced technologies do require an investment, the savings from lower energy costs and avoiding potential carbon pricing often deliver a surprisingly fast return. You have to reframe the way you think about this. It's not just an environmental cost; it's a strategic investment in building a leaner, more efficient, and more competitive business.

Ready to turn carbon management from a headache into a genuine advantage? Carbonpunk has an AI-driven platform that delivers the real-time data and clear insights you need to get to net-zero faster. Learn how our technology can streamline your emissions tracking and drive real reductions.