ISO 14067 Product Carbon Footprint Compliance Guide

Karel Maly

August 26, 2025

For Czech businesses, achieving ISO 14067 compliance for your product's carbon footprint has shifted from a "nice-to-have" to a strategic necessity. This standard isn't just another piece of paper; it’s the internationally accepted rulebook for calculating the greenhouse gas emissions of a product from start to finish. Honestly, for many companies I've worked with, it’s become the key that unlocks new markets and satisfies the growing demand for real environmental transparency.

Getting to Grips with ISO 14067 in the Czech Republic

Here in Czechia, ISO 14067 is now the gold standard for measuring a product's true environmental impact. It's not just about what goes on within your own four walls. The standard pushes you to take a much broader look, tracing a product's journey from the moment its raw materials are pulled from the earth to the day it's thrown away.

This comprehensive view is what we call a Life Cycle Assessment (LCA), and it's the heart of genuine accountability. It forces you to look past your factory's smokestacks and confront the carbon costs that are often hidden deep within your supply chain or even in how your customers use the product.

Thinking in Lifecycles

Adopting the ISO 14067 framework really is a change in perspective. Many businesses are used to a "cradle-to-gate" approach, where they only track emissions up to the point a product leaves their facility. This standard, however, demands a full "cradle-to-grave" analysis.

That means you have to account for the carbon footprint of every single stage:

- Sourcing Raw Materials: Think about the emissions from mining metals, harvesting wood, or manufacturing the initial chemicals.

- Manufacturing: This is the more familiar part—the energy used and waste created during production.

- Distribution: You need to calculate the footprint of all your logistics, from your suppliers to your warehouse and finally to the customer's doorstep.

- Product Use: For many products, like electronics or appliances, this is a huge one. How much energy does it consume over its lifetime?

- End-of-Life: What happens when the product is no longer needed? You have to consider the emissions from disposal, recycling, or decomposition.

Pulling all this together is what makes the final carbon footprint number so credible and powerful. If you want to dive deeper into how corporate emissions are categorized, our guide on the GHG Protocol for Czech businesses is a great place to start.

A verified product carbon footprint isn't just a number to put on a report. It's a clear signal of your company's commitment to transparency. More importantly, it's a practical tool that shines a light on hidden inefficiencies, helping you find real opportunities to cut carbon across your entire value chain.

National Standards and Clear Rules

The importance of this standard was cemented when EN ISO 14067:2018 was adopted as a European Standard and then implemented right here in Czechia. This brought our national approach in line with the strictest international guidelines for calculating a product's carbon footprint (CFP).

As of March 2019, any conflicting national rules were officially withdrawn. This gave Czech companies a single, clear framework for systematically measuring all greenhouse gas emissions tied to a product’s lifecycle, leaving no room for ambiguity.

Your Practical Roadmap to ISO 14067 Compliance

Talking about standards is one thing; putting them into practice is another. Let’s get into the nuts and bolts of how you actually achieve ISO 14067 product carbon footprint compliance. It’s not about ticking boxes but following a logical, structured path that turns a complex standard into a manageable project. It all starts with drawing a line in the sand.

Your first major decision is setting the system boundary for your analysis. Are you looking at a 'cradle-to-gate' assessment? This covers everything from digging raw materials out of the ground right up to your product rolling out of the factory doors. Or are you going for the full picture with a 'cradle-to-grave' analysis, which follows the product through distribution, its life with the customer, and its final disposal? To really nail ISO 14067 credibility, cradle-to-grave is the gold standard.

Defining Your Scope and Digging for Data

Let’s make this real. Imagine a fictional Czech glass manufacturer, "Bohemia Crystal Clear," looking to get its new sustainable glassware line certified. The first thing they need to do is map out the entire life story of a single wine glass.

This means tracing every single step. From mining the silica sand and the energy guzzled by a customer's dishwasher, all the way to how that glass is eventually recycled. This initial map isn't just an exercise; it sets the boundaries for everything that follows and tells you exactly what data you need to hunt down.

With the scope locked in, the real detective work begins: the inventory analysis. This is all about gathering two distinct types of data.

- Primary Data: This is the stuff you can get your hands on directly. It's information from your own operations and your immediate suppliers. For Bohemia Crystal Clear, this means pulling up their factory's electricity bills, checking the exact amount of natural gas their furnaces burn, and looking at the fuel logs for their delivery trucks.

- Secondary Data: Sometimes, you can't get data directly. This is where you lean on information from established, external sources. When our glassmaker can’t get specific emissions figures from their silica sand supplier, they’d turn to a trusted database like Ecoinvent to find a solid average emission factor for that material.

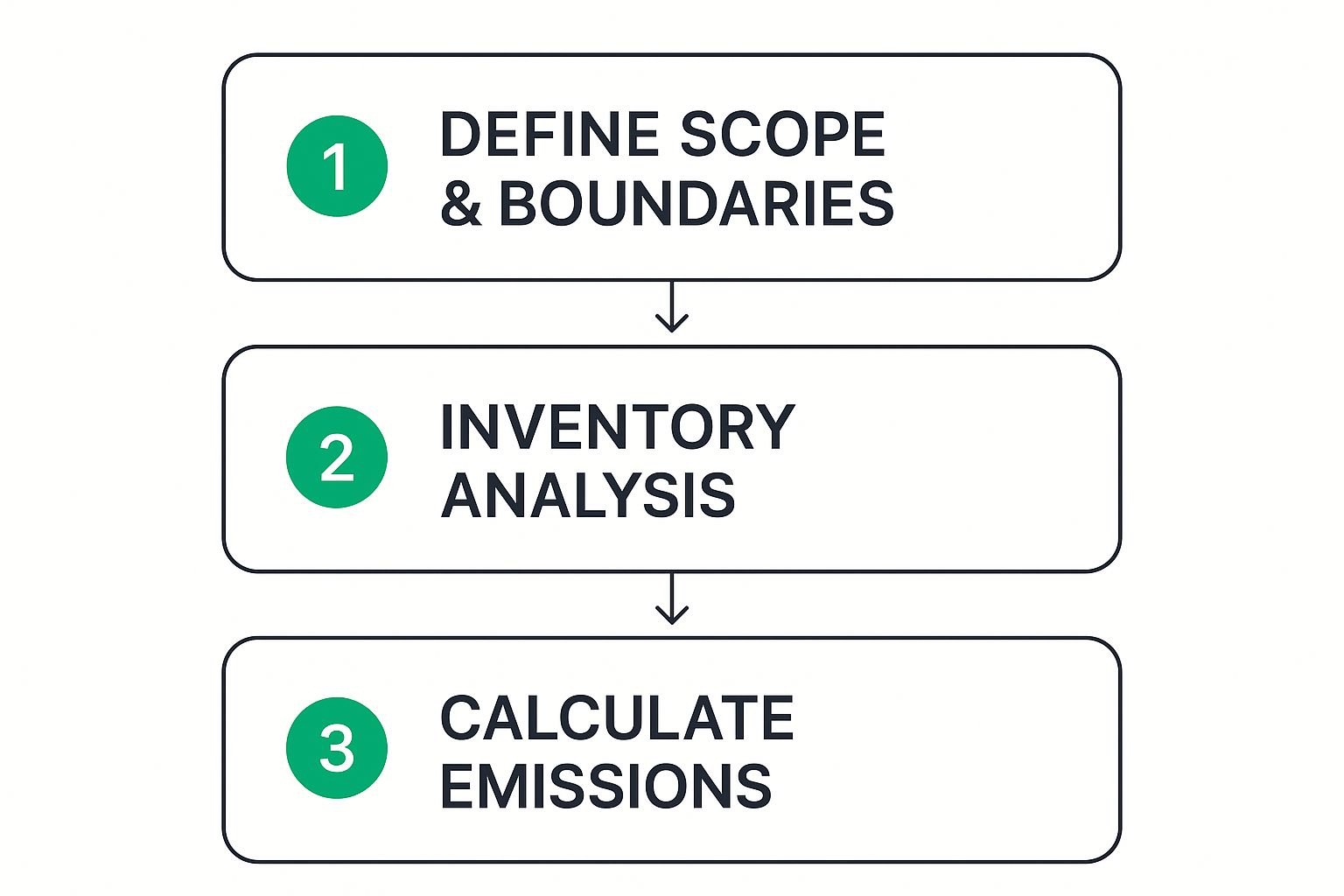

This simple infographic really nails the core sequence of any product carbon footprint study.

As you can see, defining that initial scope is the foundation. Get that wrong, and everything you build on top of it will be shaky.

Turning Raw Data into Real Impact

Now you have all this data—kilowatt-hours of electricity, litres of diesel, kilograms of raw materials. The next job is to translate it all into a single, universal metric: kilograms of carbon dioxide equivalent (kg CO₂e).

This magic happens using emission factors. Think of an emission factor as a conversion rate that tells you the emissions per unit of activity, like kg CO₂e per kilowatt-hour of electricity. The trick is to use factors that are specific to your context. For example, the emission factor for electricity in Czechia, with its unique energy mix, is going to be quite different from the one in France. You can get a much deeper understanding by mastering product-level emissions data for decarbonisation in our detailed guide.

The final CFP study report isn't just a spreadsheet. It's a comprehensive story that details your product’s carbon journey, backing up every assumption, data source, and calculation. This is the very document an external verifier will pore over to give your claim the green light.

Finally, you pull everything together into a detailed CFP study report. This document needs to be completely transparent, laying out your methodology, the boundaries you defined, the data sources you tapped, any assumptions you had to make, and, of course, the final numbers.

To create a truly solid framework for ISO 14067 compliance, it’s wise to adopt a structured approach to managing all this information, guided by principles of Information Life Cycle Management. This ensures your data is not just accurate but also meticulously organised and ready for an audit, forming the unshakable bedrock of your compliance claim.

Getting Through the Data Collection and Calculation Maze

Let’s be frank: data collection is where most ISO 14067 product carbon footprint projects stall out. It’s the single most demanding phase, where high-level ambitions collide with the messy, complex reality of your supply chain. Getting this right isn’t just a box-ticking exercise; it’s the foundation for a credible, trustworthy study.

The real grind is pulling reliable data from suppliers, especially those several steps removed from your own operations. While primary data—information you collect directly from your own facilities and direct partners—is the gold standard, getting it can feel like a constant battle. Many suppliers simply don't have the systems to track this kind of information, or they might be reluctant to share it.

This is where a bit of strategy and good communication can make all the difference. Instead of just firing off a generic questionnaire, take the time to explain why you need the data and how it helps everyone reach a common sustainability goal. I’ve found that a collaborative approach almost always gets better results than a blunt demand for numbers.

Finding and Defending Your Data Sources

When primary data just isn’t available, ISO 14067 allows you to use secondary data. This is information from public or commercial life cycle assessment (LCA) databases like Ecoinvent or GaBi, which contain industry-average emission factors for thousands of materials and processes. The keyword here, however, is justification.

You can't just grab a number that looks close enough. You need to meticulously select the most relevant data you can find and document precisely why it's the best available substitute for your specific material or process.

Here’s what to look for:

- Geographical Relevance: Always use data specific to the country or region where the activity is happening. For instance, the carbon intensity of electricity in Czechia is worlds apart from that in hydro-powered Norway.

- Technological Equivalence: Make sure the data reflects the actual technology being used. A modern, hyper-efficient steel mill will have a very different footprint than an older facility.

- Temporal Accuracy: Data gets stale. Always use the most up-to-date emission factors you can find, as they change over time with new technologies and evolving energy grids.

One of the biggest mistakes I see is when companies mix high-quality primary data from their own factories with low-quality, generic secondary data from suppliers. An auditor will spot that inconsistency from a mile away, and it can seriously undermine the credibility of your entire CFP analysis.

Managing this massive influx of information and calculations demands order. Implementing solid document version control best practices isn't just a good idea; it's essential for keeping your project auditable and error-free. Every change to a data point or calculation needs a clear, traceable history.

A Practical Look at Data Sources

Choosing between primary and secondary data is a constant balancing act. Here's a quick breakdown to help you decide which is right for different parts of your analysis.

Choosing the Right Data for Your CFP Analysis

| Data Type | Definition | Pros | Cons | Best Used For |

|---|---|---|---|---|

| Primary Data | Data collected directly from your own operations or suppliers (e.g., energy bills, transport logs). | Highly accurate and specific to your product. Increases credibility. | Can be time-consuming and difficult to obtain, especially from deep in the supply chain. | Your own manufacturing processes, final assembly, and Tier 1 suppliers where you have strong relationships. |

| Secondary Data | Data from third-party databases (e.g., Ecoinvent, GaBi) representing industry averages. | Readily available and covers a vast range of materials and processes. | Less accurate as it's not specific to your supply chain. Requires careful justification. | Raw material extraction, processes from upstream suppliers (Tier 2 and beyond), and when primary data is impossible to get. |

Ultimately, a robust CFP study often uses a hybrid approach—relying on primary data where you can get it and supplementing with carefully justified secondary data where you can't.

Dealing With Complex Calculation Scenarios

Once you have the data, you have to apply it correctly, and that opens up its own set of challenges. Two of the most common stumbling blocks I see are allocation and handling biogenic carbon.

Allocation is a puzzle you have to solve when a single facility or process creates more than one product. Imagine a chemical plant making your target product alongside several co-products. How do you fairly split the factory’s total energy use and emissions between them? ISO 14067 provides a clear hierarchy of methods, starting with physical properties like mass or volume. If that isn't feasible, you can move to allocation based on economic value. The key is to pick a logical method and apply it consistently.

Biogenic carbon is another tricky area. This refers to the carbon stored in natural materials like wood, paper, or cotton. When these products are burned at the end of their life, they release that stored carbon back into the atmosphere. The standard requires you to track these emissions separately from fossil fuel emissions because they are treated differently in climate science. Getting this wrong can throw off your final footprint significantly.

Why Verification and Reporting Are Non-Negotiable

Let's be blunt: a calculated product carbon footprint is just a number until it's been properly scrutinised. This is where third-party verification comes in, and it’s absolutely essential for achieving credible ISO 14067 product carbon footprint compliance. It’s the critical process that turns your internal study into a trusted, public-facing claim.

Think of verification as an impartial review of your entire Carbon Footprint of a Product (CFP) study. An independent auditor meticulously examines your data, methodology, and calculations to ensure everything aligns with the standard's strict rules. They are your critical friend, making sure your final figure is both accurate and defensible.

What Auditors Are Really Looking For

Experienced auditors can spot inconsistencies from a mile away. They'll dig deep into the core components of your report to confirm its integrity.

Here's a breakdown of their typical focus:

- System Boundaries: Did you correctly define the scope of your analysis? Whether it’s cradle-to-gate or cradle-to-grave, they’ll check that your boundaries make sense.

- Data Quality: Is your primary data traceable and reliable? If you used secondary data from databases like Ecoinvent, is its use well-justified and relevant to your product?

- Calculation Accuracy: Were the emission factors applied correctly? Are the final calculations free of errors? It’s amazing how often small mistakes can slip in.

- Report Transparency: Have you clearly documented every assumption, limitation, and methodology used in the study? Ambiguity is a red flag for auditors.

If you’re looking for more specialised guidance on this process, it can be helpful to review established audit and compliance frameworks for environmental services.

A smooth audit all comes down to meticulous preparation. An auditor knows immediately if a CFP report was rushed or if the data is a mess. Your goal should be to present a report that tells a clear, logical, and evidence-backed story of your product’s carbon journey.

The professional demand for this kind of expertise in Czechia has been growing significantly. We’ve seen this firsthand with the increasing popularity of specialised training, like the 'ISO 14067 Lead Implementer' program offered since early 2025. This surge reflects a wider corporate need for Czech companies to align with EU climate policies. By upskilling professionals, this education helps embed product carbon footprinting into everyday decision-making, from setting reduction targets to improving environmental communication.

Communicating Your Results Without Greenwashing

Once your footprint is verified, the next hurdle is sharing it with the world. This is a golden opportunity to build genuine trust, but it’s also a minefield of potential greenwashing. Honesty and context are your best friends here.

Dodge vague claims like "eco-friendly" at all costs. Instead, present the verified data clearly and proudly—on your packaging, website, or in sustainability reports.

True transparency means giving the full picture, including the scope of your assessment. When done right, effective reporting transforms a compliance task into a powerful market advantage, showcasing your commitment to accountability. For more detailed strategies, our guide on carbon footprint tracking for manufacturing and reduction is a great next step. This is how you turn all that hard work into real, tangible brand value.

Turning Compliance into a Competitive Advantage

It’s easy to look at ISO 14067 product carbon footprint compliance and see just another box to tick. But treating it as a simple regulatory chore is a massive missed opportunity. From what I’ve seen, the most forward-thinking Czech companies are using this process as a powerful strategic tool.

Think of it like getting a detailed X-ray of your product's entire lifecycle. Suddenly, you're uncovering hidden inefficiencies you never knew were there. This isn't about vague sustainability talk; it's about getting granular data that leads to measurable improvements. You can pinpoint exactly where energy is being wasted or which raw materials carry a surprisingly high carbon cost. That kind of insight leads directly to smarter operational decisions and, yes, real cost savings.

Unlocking New Market Opportunities

In today's market, having a verified product carbon footprint isn't just a nice-to-have; it's a serious competitive edge. It sends a clear signal to both your B2B customers and everyday shoppers that your commitment to sustainability is real and backed by internationally recognised standards. This can open doors you didn't even know were there and solidify your place in the markets you already serve.

Compliance helps you build genuine brand value based on trust and transparency. Here’s how:

- Winning over B2B Customers: More and more, large corporations are demanding detailed emissions data from their suppliers to meet their own Scope 3 reporting needs. If you have it ready, you’re already ahead of the pack.

- Appealing to Eco-Conscious Consumers: For a growing number of shoppers, a lower carbon footprint is the deciding factor when they're choosing between two similar products on a shelf.

- Building Lasting Brand Value: When you can back up your claims with verified data, you foster loyalty and position your brand as a true leader in corporate responsibility.

Achieving compliance isn't the finish line; it's the starting gate. The real value comes from using the data to drive continuous improvement, innovate your processes, and tell a compelling story of environmental stewardship.

Demonstrating Responsibility in a Czech Context

Solid product-level accounting is also a critical way to demonstrate corporate responsibility, especially when you consider Czechia’s unique environmental situation. The country's emissions have been declining slower than the EU average, putting pressure on businesses to step up.

Adding another layer of complexity is the state of Czech forestry. Since 2018, due to severe bark beetle outbreaks, the forests have shockingly flipped from being a carbon sink to a net source of emissions. This local reality, detailed in a European Parliament briefing on Czechia's climate action, makes it even more vital for companies to rigorously account for their own product emissions.

By meticulously measuring your product's impact, you're not just following a standard; you're contributing positively to the national effort and showcasing proactive environmental management. This is what it means to turn compliance into a competitive advantage—using verified data not just to meet the rules, but to innovate, save money, and build a more resilient and respected brand for the future.

Your ISO 14067 Questions, Answered

When businesses first start digging into the ISO 14067 standard for product carbon footprints, a lot of practical questions pop up. Let's walk through some of the most common ones we get asked, clearing up the confusion with straightforward answers drawn from our experience.

How Long Does a Product Carbon Footprint Study Actually Take?

This is usually the first question on everyone's mind, and the honest answer is, "it depends." For a relatively simple product where your supply chain is local and you have solid data, you might be looking at 4-6 weeks.

But what if you’re making a complex electronic device with components sourced from all over the world? In that case, the timeline could easily extend to 3-6 months, sometimes longer. The biggest hurdle is almost always the data collection—chasing down reliable information from dozens of suppliers.

What's the Real Difference Between Cradle-to-Gate and Cradle-to-Grave?

I see a lot of confusion around these terms, but understanding the distinction is absolutely fundamental because it sets the boundaries for your entire analysis.

-

Cradle-to-Gate: This analysis measures everything from the moment raw materials are pulled from the earth up until the finished product rolls out of your factory doors. It's a great starting point, but it's not the whole story.

-

Cradle-to-Grave: This is the full picture. It includes everything in the cradle-to-gate scope plus all the emissions generated during distribution, customer use, and eventually, the product's disposal or recycling.

For genuine ISO 14067 compliance that stands up to scrutiny from customers and regulators, a cradle-to-grave analysis is what you need. It’s the only way to present a truly transparent and complete view of your product's impact on the planet.

Is ISO 14067 a Legal Requirement in the EU?

This is a big one. As of right now, ISO 14067 is not a mandatory law across the European Union that every company must follow. It's technically a voluntary standard.

However—and this is a big "however"—it's quickly becoming a commercial necessity. Many large corporations, particularly those grappling with new rules like the Corporate Sustainability Reporting Directive (CSRD), are now demanding this data from their suppliers. In practice, complying with ISO 14067 is becoming the ticket to play in major European supply chains.

Ready to move beyond questions and start building a credible, compliant product carbon footprint? Carbonpunk’s AI-driven platform helps automate the heavy lifting of data collection, analysis, and reporting, making your ISO 14067 journey far smoother. See how you can turn compliance into a real competitive edge at https://www.carbonpunk.ai/en.