Top Carbon Footprint Reduction Strategies for Transportation Companies

Karel Maly

August 19, 2025

In an era where sustainability is no longer a choice but a business imperative, transportation companies face increasing pressure to minimise their environmental impact. Customers, investors, and regulators are demanding clear action on decarbonisation. For an industry that forms the backbone of the global economy, this presents a significant challenge. However, it also offers a unique opportunity for innovation, efficiency, and competitive advantage. The journey to a lower-carbon future requires more than just good intentions; it demands a strategic, data-driven approach.

This article outlines seven high-impact carbon footprint reduction strategies for transportation companies, moving beyond generic advice to provide actionable insights for real-world application. From leveraging advanced technology to rethinking traditional logistics models, these strategies provide a comprehensive roadmap for transforming your operations. We will explore practical steps for fleet electrification, route optimisation, modal shifts, and last-mile innovations.

Platforms like Carbonpunk, which automate emissions tracking and provide AI-driven recommendations, are becoming indispensable tools in this transition. They help companies measure what matters and turn sustainability goals into operational reality. By implementing these focused strategies, your organisation can effectively meet the demands of a greener economy and secure a more sustainable future.

1. Fleet Electrification

One of the most impactful carbon footprint reduction strategies for transportation companies is the systematic transition from internal combustion engine (ICE) vehicles to electric vehicles (EVs). Fleet electrification involves replacing traditional diesel and petrol-powered assets with battery-electric or hydrogen fuel cell alternatives, effectively eliminating direct tailpipe emissions from vehicle operations. This move represents a fundamental shift in operational strategy, moving away from fossil fuel dependency towards a more sustainable and often more economical model.

The Case for Electrification

The primary benefit of electrification is the complete removal of tailpipe CO₂, NOx, and particulate matter emissions, which directly improves local air quality and contributes significantly to decarbonisation goals. While the electricity source matters for the overall lifecycle emissions, the operational impact is immediate. Industry leaders are already demonstrating the viability of this strategy. For instance, Amazon's commitment to deploying 100,000 Rivian electric vans and UPS's integration of over 13,000 alternative fuel and advanced technology vehicles highlight the scalability of this approach for last-mile and urban deliveries.

Strategic Implementation

A successful transition requires careful planning and a phased approach. A practical starting point for many companies is to electrify vehicles used for shorter, predictable urban routes where range anxiety is minimal and return-to-base charging is feasible.

Here are some actionable steps for implementation:

- Conduct a Total Cost of Ownership (TCO) Analysis: Evaluate the long-term financial case by comparing EVs and ICE vehicles. Factor in lower fuel (electricity) costs, reduced maintenance needs, and available government incentives against the higher initial purchase price and infrastructure investment.

- Start with a Pilot Programme: Before a full-scale rollout, deploy a small number of EVs on specific routes to gather real-world data on performance, charging needs, and driver feedback. This helps identify and solve operational challenges early.

- Develop Charging Infrastructure: Partner with specialised providers to design and install the necessary charging infrastructure at depots. Consider smart charging solutions that optimise energy consumption and cost by scheduling charging during off-peak hours.

- Train Your Team: Drivers need training on EV-specific techniques, such as regenerative braking, to maximise range and operational efficiency. Maintenance staff will also require new skills and tools to service electric powertrains.

Leading the charge in sustainable transport, companies can look to manufacturers like BYD electric vehicles for a wide range of electric vehicles suitable for various fleet needs.

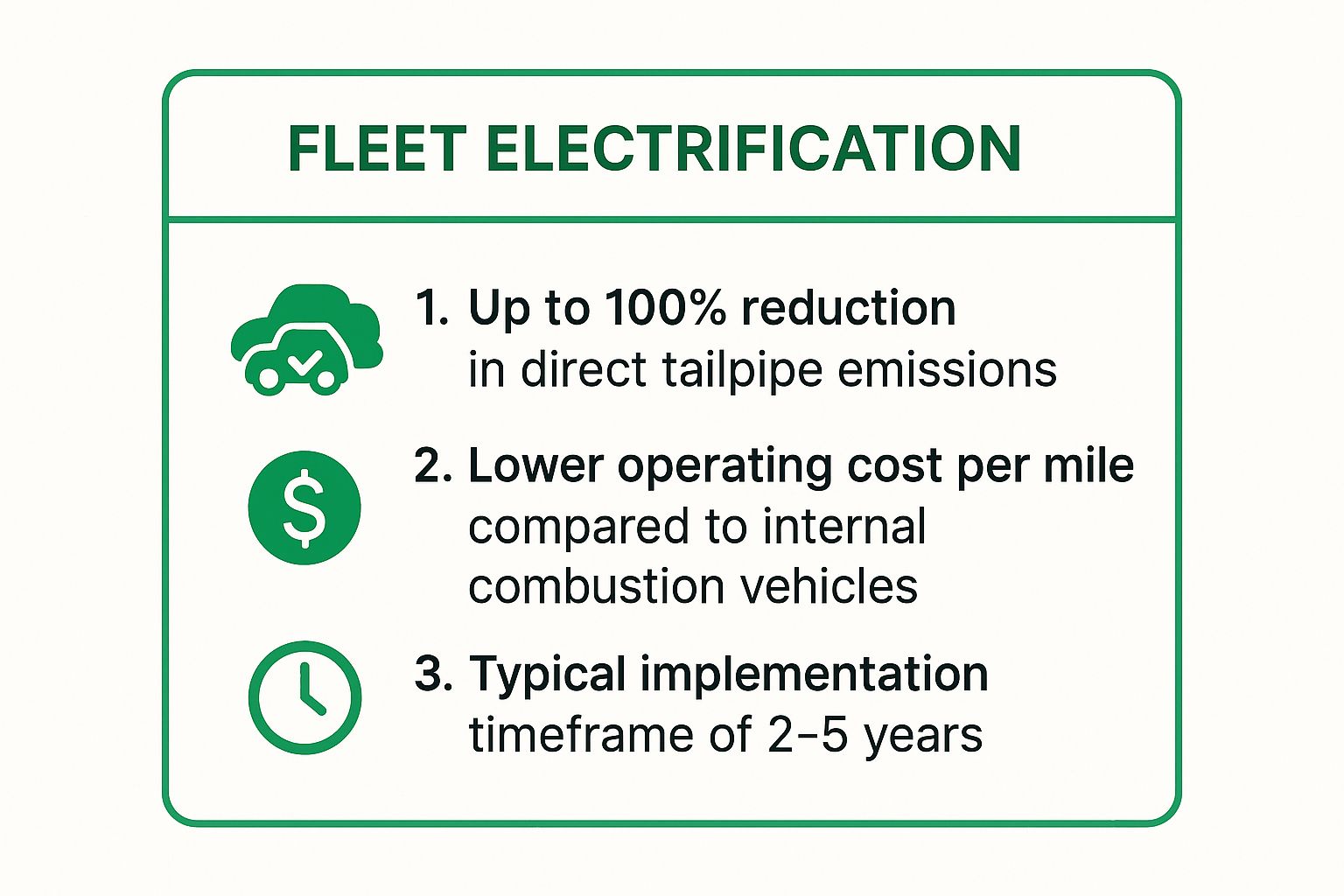

This summary highlights the core benefits and timeline for a typical electrification project.

As the data shows, the complete elimination of direct emissions combined with lower operating costs makes electrification a powerful, long-term strategy for both environmental and financial sustainability.

2. Route Optimisation and Smart Logistics

Beyond upgrading vehicle hardware, one of the most immediate and cost-effective carbon footprint reduction strategies for transportation companies lies in optimising the very paths those vehicles take. Route optimisation uses advanced software, AI, and real-time data to plan the most efficient journeys. This approach goes beyond simply finding the shortest distance; it considers traffic, delivery windows, vehicle capacity, and even factors like traffic light patterns to minimise fuel consumption, reduce total miles travelled, and eliminate unnecessary idling.

The Case for Intelligent Planning

The core benefit of smart logistics is its ability to reduce fuel burn and associated emissions without significant capital investment in new vehicles. By making existing assets more productive, companies can achieve substantial operational and environmental wins. Industry giants have proven the immense value of this strategy. UPS's renowned ORION (On-Road Integrated Optimisation and Navigation) system, for example, saves the company an estimated 100 million miles and 10 million gallons of fuel annually, showcasing how intelligent planning directly translates to massive carbon savings. Similarly, Walmart reduced its fleet miles by 15% through advanced route optimisation.

Strategic Implementation

Deploying a successful route optimisation strategy involves integrating technology with operational processes to create a dynamic and responsive logistics network. For transportation companies looking to optimise routes and improve overall fleet efficiency, a comprehensive GPS fleet management guide can offer detailed insights into leveraging technology for significant carbon reductions.

Here are some actionable steps for implementation:

- Integrate Telematics and GPS Data: Equip your fleet with modern telematics systems to gather real-time data on vehicle location, speed, fuel consumption, and engine diagnostics. This data is the foundation for any effective optimisation software.

- Leverage AI and Machine Learning: Adopt advanced software platforms that use machine learning to continuously analyse route performance and historical data. These systems can predict traffic patterns, suggest more efficient delivery sequences, and adapt to unforeseen delays.

- Factor in All Variables: Ensure your system accounts for all relevant constraints, including driver hours, delivery time windows, vehicle load capacities, and road restrictions. This holistic approach prevents operational bottlenecks and maximises efficiency.

- Establish a Feedback Loop: Create a system for drivers to provide real-world feedback on planned routes. Their on-the-ground insights can help refine algorithms and correct inaccurate map data, making the system smarter over time.

For a deeper dive into the technologies and methods behind this strategy, you can explore this modern logistics route planning guide.

3. Modal Shift to Rail and Water Transport

Another powerful carbon footprint reduction strategy for transportation companies involves a strategic modal shift away from road and air freight towards more carbon-efficient alternatives like rail and water. This intermodal approach leverages the inherent efficiencies of trains and ships, which can move massive volumes of goods over long distances using significantly less fuel per tonne-kilometre compared to trucks or planes. By integrating these modes into the supply chain, companies can dramatically reduce their overall emissions for long-haul segments.

The Case for Intermodal Transport

The core advantage of shifting modes is the substantial reduction in greenhouse gas emissions. According to the European Environment Agency, rail transport emits a fraction of the CO₂ per tonne-kilometre compared to heavy-duty road transport, while maritime shipping is even more efficient for transcontinental journeys. This makes it an essential strategy for decarbonising long-distance freight. Major logistics players are already capitalising on this, with companies like Amazon increasingly using rail for coast-to-coast shipping to cut both costs and emissions, and Maersk seamlessly integrating sea and rail transport to create more sustainable end-to-end supply chains.

Strategic Implementation

A successful transition to intermodal transport requires careful analysis of freight characteristics and building strong partnerships within the logistics network. It is best suited for non-urgent, high-volume cargo travelling over long, established corridors.

Here are some actionable steps for implementation:

- Analyse Cargo Suitability: Evaluate which freight routes and cargo types are suitable for a modal shift. Bulk goods, containerised products, and non-perishable items travelling over 500 kilometres are often ideal candidates.

- Develop Strategic Partnerships: Build strong relationships with rail freight operators and shipping lines. Collaborating with intermodal leaders like BNSF Railway or Hub Group can provide access to established networks and expertise.

- Invest in Intermodal Connectivity: Ensure seamless transitions by utilising or investing in intermodal terminals. The use of standardised containers is critical for efficient transfers between ships, trains, and final-delivery trucks.

- Plan for Adjusted Timelines: Rail and sea transport typically have longer transit times than road or air. Adjust inventory management and supply chain planning to accommodate these schedules, balancing speed with sustainability goals.

4. Alternative Fuels Adoption

Beyond full electrification, adopting alternative and renewable fuels offers a powerful, immediate pathway for transportation companies to reduce their carbon footprint. This strategy involves transitioning from conventional diesel and petrol to lower-carbon options like biodiesel, renewable natural gas (RNG), and hydrogen. A key advantage is that many of these fuels can be used in existing or slightly modified internal combustion engines, minimising the need for a complete fleet overhaul and large-scale infrastructure investment.

The Case for Alternative Fuels

The primary benefit of alternative fuels lies in their ability to significantly lower lifecycle carbon emissions. While tailpipe emissions may still exist, the "well-to-wheel" carbon intensity is often drastically reduced, especially with fuels derived from waste or renewable sources. This makes them a critical tool for decarbonising heavy-duty and long-haul transport where battery-electric solutions are not yet mature. For example, Waste Management now powers over 60% of its fleet with RNG, and UPS operates one of the world's largest private alternative fuel fleets, utilising compressed natural gas (CNG) and renewable diesel to great effect.

Strategic Implementation

Integrating alternative fuels requires a careful assessment of fuel availability, vehicle compatibility, and operational impact. This approach serves as one of the most practical carbon footprint reduction strategies for transportation companies with diverse fleets and routes.

Here are some actionable steps for implementation:

- Assess Local Fuel Availability: Investigate the regional supply and infrastructure for fuels like RNG, biodiesel, or hydrogen. The viability of this strategy often depends on a reliable and cost-effective local fuel source.

- Start with "Drop-in" Fuels: Begin the transition with fuels such as renewable diesel or biodiesel blends, which are chemically similar to conventional diesel and require no engine modifications. This allows for an immediate emissions reduction with minimal operational disruption.

- Analyse Total Lifecycle Emissions: Look beyond the tailpipe and evaluate the complete carbon footprint of each fuel option, from production to combustion. This ensures your chosen fuel aligns with genuine, long-term sustainability goals.

- Evaluate Cost Stability and Incentives: Compare the long-term cost stability of alternative fuels against volatile fossil fuel prices. Also, research government grants, tax credits, or subsidies available for adopting cleaner fuels, which can significantly improve the business case.

- Train Maintenance Teams: Ensure your maintenance staff are properly trained to service vehicles running on new fuels. While many systems are similar, specific components and diagnostic procedures may differ.

5. Vehicle Load Optimisation and Consolidation

A cornerstone of efficient and sustainable logistics is ensuring that every vehicle journey is as productive as possible. Vehicle load optimisation and consolidation focus on maximising the use of a truck’s available capacity, both by weight and volume. This strategy reduces the total number of trips required to move a given amount of goods, which directly cuts fuel consumption, mileage, and associated carbon emissions per unit of cargo. It transforms partially full trucks into a significant liability and empty space into an opportunity for carbon reduction.

The Case for Consolidation

The primary benefit of this strategy is improved asset utilisation, which leads to fewer trucks on the road and a lower collective carbon footprint. Maximising each load means that the fuel burned and emissions produced are spread across a larger volume of goods, enhancing overall transport efficiency. Retail giants exemplify this principle in action. For instance, Walmart’s sophisticated cross-docking and backhauling systems have enabled them to achieve exceptionally high truck utilisation rates, while Amazon's algorithms dynamically consolidate packages to ensure delivery vans are filled to capacity, minimising trips in residential areas.

Strategic Implementation

Effective load optimisation requires a blend of technology, process, and sometimes collaboration. It moves beyond simple dispatching to a data-driven approach where every cubic metre of cargo space is a valuable asset.

Here are some actionable steps for implementation:

- Invest in a Transportation Management System (TMS): Modern TMS platforms, like those from Manhattan Associates or Oracle, use advanced algorithms to plan optimal loads based on shipment dimensions, weight, destination, and delivery windows.

- Utilise Dimensioning Technology: Implement automated dimensioning and weighing systems at docks to capture precise cargo data. This accurate information is crucial for software to build dense, stable, and maximised loads.

- Foster Collaborative Shipping: Form partnerships with other shippers whose routes and needs complement your own. Sharing space on less-than-truckload (LTL) shipments through collaborative platforms or 3PL providers like C.H. Robinson can turn empty miles into revenue-generating, emission-saving miles.

- Analyse Historical Data: Regularly review load data to identify patterns of underutilisation. Use these insights to renegotiate with suppliers for more efficient packaging or adjust pickup schedules to allow for better consolidation opportunities.

This approach is one of several critical carbon footprint reduction strategies for transportation companies, forming part of a wider effort to improve operational efficiency. By ensuring vehicles are consistently full, organisations can achieve substantial cost savings and environmental benefits simultaneously. You can explore how these tactics fit into a broader decarbonisation plan by learning more about strategies to reduce supply chain carbon emissions.

6. Driver Training and Eco-Driving Programmes

Beyond vehicle technology and operational planning, the single most influential factor in day-to-day fuel consumption is the driver. Comprehensive driver training and eco-driving programmes are powerful carbon footprint reduction strategies for transportation companies that focus on influencing behaviour behind the wheel. These initiatives equip drivers with the knowledge and skills to operate vehicles more efficiently, directly translating into lower fuel usage and reduced emissions.

The Case for Eco-Driving

The core benefit of eco-driving programmes is their ability to generate significant fuel savings and emissions reductions with minimal capital investment. By optimising driver behaviour, companies can unlock efficiency gains that are otherwise inaccessible. For example, Prime Inc.'s extensive eco-driving training has been shown to reduce its fleet's fuel consumption by up to 8%. Similarly, Werner Enterprises uses detailed driver scorecards to foster a culture of continuous improvement, proving that engaged drivers are a company's greatest asset in sustainability.

Strategic Implementation

A successful eco-driving programme is built on education, consistent monitoring, and positive reinforcement. It integrates seamlessly with existing safety protocols, creating a holistic approach to driver performance that benefits both the environment and the bottom line.

Here are some actionable steps for implementation:

- Leverage Telematics for Coaching: Use data from telematics systems to provide real-time, in-cab feedback on behaviours like harsh braking, rapid acceleration, and excessive idling. This allows for immediate correction and reinforcement of good habits.

- Create Incentive Schemes: Implement driver competitions, leaderboards, and reward systems based on fuel efficiency metrics. Recognising top performers fosters healthy competition and motivates the entire team to improve.

- Provide Regular Performance Feedback: Schedule regular, constructive feedback sessions where managers can review performance data with drivers. Use scorecards to track progress over time and celebrate improvements.

- Integrate Maintenance Awareness: Train drivers on the importance of pre-trip inspections, proper tyre pressure, and reporting maintenance issues promptly, as well-maintained vehicles are inherently more efficient.

Organisations like the American Transportation Research Institute provide valuable research that underpins the effectiveness of these driver-centric approaches.

7. Last-Mile Delivery Innovation

Among the most effective carbon footprint reduction strategies for transportation companies is targeting the final, most carbon-intensive leg of the supply chain. Last-mile delivery innovation involves deploying smaller, more efficient, and often zero-emission solutions like electric cargo bikes, autonomous robots, drones, and micro-fulfilment centres to replace traditional vans for the final delivery segment. This approach directly addresses the inefficiencies of urban logistics, where frequent stops, traffic congestion, and low drop density inflate emissions.

The Case for Last-Mile Innovation

The primary benefit of innovating the last mile is a dramatic reduction in CO₂, NOx, and particulate matter emissions within densely populated urban areas, leading to healthier communities. These solutions also often decrease operational costs by lowering fuel consumption and vehicle maintenance needs. Global leaders are proving the model's effectiveness: UPS is successfully using e-bike delivery fleets in European cities, while Wing (an Alphabet company) and Amazon Prime Air are pioneering drone delivery services, showcasing how technology can create cleaner, faster, and more efficient final-mile logistics.

Strategic Implementation

Adopting innovative last-mile solutions requires a tailored strategy that matches the technology to the specific operational environment. A phased rollout, beginning in areas with high delivery density, is often the most practical path to successful integration and scaling.

Here are some actionable steps for implementation:

- Identify Suitable Urban Zones: Begin by analysing delivery data to pinpoint high-density routes where smaller vehicles or drones can operate most efficiently. These areas offer the quickest return on investment and the most significant environmental impact.

- Establish Micro-Fulfilment Centres: Set up small, localised urban warehouses or consolidation centres. These hubs allow for bulk deliveries from larger trucks, with final-mile distribution handled by eco-friendly alternatives like e-cargo bikes or walkers.

- Pilot New Technologies: Start a pilot programme with a specific technology, such as autonomous delivery robots from Starship Technologies or a fleet of electric cargo bikes. This allows you to test operational feasibility, assess regulatory hurdles, and measure customer acceptance. More details about these approaches can be found in this guide to last-mile delivery solutions.

- Engage with Local Authorities: Proactively partner with municipal governments to navigate regulations for drones, autonomous vehicles, and sidewalk usage. Collaboration can help shape policies that support sustainable urban logistics.

By rethinking the final delivery step, companies can achieve substantial emission reductions while simultaneously enhancing service speed and operational agility in congested city centres.

Carbon Footprint Reduction Strategies Comparison

| Strategy | Implementation Complexity 🔄 | Resource Requirements ⚡ | Expected Outcomes 📊 | Ideal Use Cases 💡 | Key Advantages ⭐ |

|---|---|---|---|---|---|

| Fleet Electrification | High upfront investment; 2-5 years conversion | Significant capital; charging infrastructure | Up to 100% direct emission reduction | Urban & short-haul routes; sustainability | Zero tailpipe emissions; lower operating costs |

| Route Optimization & Smart Logistics | Moderate; 3-12 months, requires data systems | Advanced software; data integration | 10-25% transportation emission reduction | All fleet sizes; delivery efficiency | Immediate fuel savings; scalable; dynamic routing |

| Modal Shift to Rail & Water | Moderate; 6 months to 2 years; infrastructure needed | Intermodal terminals and coordination | 60-80% reduction vs. long-haul trucking | Long-distance, bulk cargo transport | High capacity; cost-effective; reduced congestion |

| Alternative Fuels Adoption | Moderate; 3-18 months; depends on fuel type | Fuel supply chain adjustments; possible engine mods | 20-80% lifecycle emissions reduction | Fleets retaining existing vehicles | Immediate emission cuts; existing infrastructure compatible |

| Vehicle Load Optimization & Consolidation | Low to moderate; 2-6 months; planning software | Load planning tools; collaboration networks | 15-30% CO2 reduction via improved utilization | Maximizing fleet efficiency; cost reduction | Reduces trips; improves asset use; lowers fuel use |

| Driver Training & Eco-Driving Programs | Low; 1-3 months to launch; ongoing reinforcement | Training programs; telematics for feedback | 5-15% emissions reduction | Every fleet; improving driver behavior | Low cost; immediate fuel savings; safety benefits |

| Last-Mile Delivery Innovation | Moderate to high; 6 months to 2 years; tech dependent | Investment in novel vehicles/robots/drones | 50-100% reduction in last-mile emissions | Dense urban areas; final delivery segment | Emission elimination; congestion reduction; customer satisfaction |

Driving the Future: Integrating Strategy with Action

The journey towards a low-carbon transportation future is not defined by a single, monolithic solution. Instead, as we have explored, it is a mosaic of interconnected and mutually reinforcing initiatives. The most effective carbon footprint reduction strategies for transportation companies blend high-impact technological investments with foundational operational excellence.

From the transformative potential of fleet electrification and alternative fuels to the immediate efficiency gains from route optimisation and eco-driving programmes, each strategy plays a critical role. The key is to move beyond a piecemeal approach and develop a holistic, integrated roadmap. This involves understanding that a successful modal shift to rail might depend on optimised first- and last-mile logistics, just as the ROI of an electric vehicle fleet is maximised by smart charging infrastructure and efficient route planning.

From Insights to Impact: Your Strategic Next Steps

The transition from understanding these strategies to implementing them effectively requires a clear, data-centric plan. For logistics managers and sustainability officers, the path forward involves several concrete actions:

- Establish a Baseline: You cannot improve what you do not measure. The first step is to gain a precise, granular understanding of your current emissions profile across all operations, from long-haul freight to urban deliveries.

- Prioritise Initiatives: Not all strategies will deliver the same value for every organisation. Use your baseline data to identify the biggest emission hotspots and model the potential impact and cost of various interventions. This will allow you to focus resources where they will drive the most significant change.

- Foster a Culture of Sustainability: Engage your entire team, especially drivers and logistics planners. Comprehensive training programmes and performance incentives are crucial for ensuring that operational best practices, like eco-driving and efficient load consolidation, become standard procedure.

- Embrace Technology as an Enabler: Leverage telematics, AI-powered logistics software, and advanced analytics platforms. These tools are no longer optional but essential for unlocking new levels of efficiency, monitoring progress, and ensuring compliance with evolving regulations. To successfully drive the future of sustainable transport, companies must also master robust data-driven resource allocation strategies.

Ultimately, embedding these carbon footprint reduction strategies for transportation companies into the core of your business is more than a compliance exercise. It is a strategic imperative that builds operational resilience, enhances brand reputation, attracts top talent, and secures a competitive advantage in a rapidly evolving global market. By taking decisive, data-informed action today, you are not just reducing your carbon footprint; you are building a more efficient, profitable, and sustainable enterprise for tomorrow.

Ready to move from strategy to action with precision and confidence? Carbonpunk provides an automated carbon management platform that gives you a real-time, granular view of your transportation emissions. Start making data-driven decarbonisation decisions today by visiting Carbonpunk.