Ultimate Product Lifecycle Assessment (LCA) Guide | Improve Sustainability

Karel Maly

September 28, 2025

When we talk about a product's environmental footprint, it’s easy to focus only on the obvious stuff, like the energy used in a factory. But that’s just one small piece of a much larger puzzle. A Product Lifecycle Assessment (LCA) gives us the whole picture. It’s a deep dive into a product’s entire journey, from the moment its raw materials are pulled from the earth to the day it’s thrown away. This is often called a cradle-to-grave analysis, and it's the only way to get a true, honest look at a product's impact.

So, What Is a Product Lifecycle Assessment, Really?

Think about a simple cotton t-shirt. Its life story is so much more than just its time being made or hanging in a shop. An LCA is the method we use to tell that full story, evaluating the environmental baggage that comes with every single step of its existence.

Instead of just taking a snapshot of one stage, like manufacturing, an LCA uses a wide-angle lens. It captures everything. This holistic view is crucial because, more often than not, a product's biggest environmental problems are hidden in places you might not expect, far away from the factory floor.

Following the Journey of a Cotton T-shirt

To really get a feel for this, let's trace the path of that t-shirt. Its journey doesn't start in a workshop, but out in a cotton field. This is where the first, and often heaviest, environmental costs add up.

- Raw Material Extraction: This phase covers everything needed to grow the cotton. We’re talking about land use, fertilisers, pesticides, and a staggering amount of water—it can take up to 2,700 litres of water to produce the cotton for just one t-shirt.

- Manufacturing and Processing: Once harvested, the cotton is processed into yarn, woven into fabric, and dyed. Every one of these steps uses more energy, water, and chemicals, all while creating wastewater and other emissions.

- Distribution and Transportation: The finished t-shirt gets packaged and shipped. It might travel from a factory to a warehouse, then to a shop, and finally to your wardrobe. Each leg of that journey, whether by truck, ship, or plane, adds to its carbon footprint.

But the story doesn't stop once you buy it. The 'use' phase is a huge part of the lifecycle that often gets ignored. Think about all the energy and water consumed every time that t-shirt is washed and dried over the years.

Finally, every product reaches its end. What happens when the t-shirt is old and worn out? Does it end up in a landfill? Is it incinerated? Or is it recycled into new fibres? Each path has a vastly different environmental outcome.

More Than a Report—It’s a Strategic Tool

By adding up all the resources used and pollution created at every stage, an LCA gives us a detailed environmental balance sheet. It goes way beyond just a carbon footprint to look at other critical issues like water scarcity, toxicity to ecosystems, and land degradation.

An LCA is what turns vague sustainability goals into a clear, actionable roadmap. It shines a spotlight on the "environmental hotspots"—those specific stages in the product's life where the damage is greatest and where making a change will do the most good.

This makes an LCA a powerful strategic tool, not just a box-ticking exercise. A good product lifecycle assessment guide helps a business see exactly where to focus its efforts to make a real difference. For our t-shirt company, the LCA might show that the biggest environmental hit isn't from the factory, but from the incredible amount of water used to grow the cotton. With that knowledge, they could switch to sourcing organic cotton or invest in better irrigation, creating a genuinely more sustainable product from the ground up.

The Four Standard Stages of an LCA

To make sure every Product Lifecycle Assessment is consistent, trustworthy, and can be compared apples-to-apples, the process is built on a standardised four-stage framework. This structure, laid out in the ISO 14040 and 14044 standards, acts as the blueprint for any legitimate LCA. Think of it as the universal rulebook for environmental impact analysis, ensuring everyone is playing the same game.

Each stage flows logically into the next, breaking down a huge, complex question into a series of much more manageable steps. Let’s walk through this process to see how a high-level goal gets transformed into tangible, actionable environmental insights.

Stage 1: Goal and Scope Definition

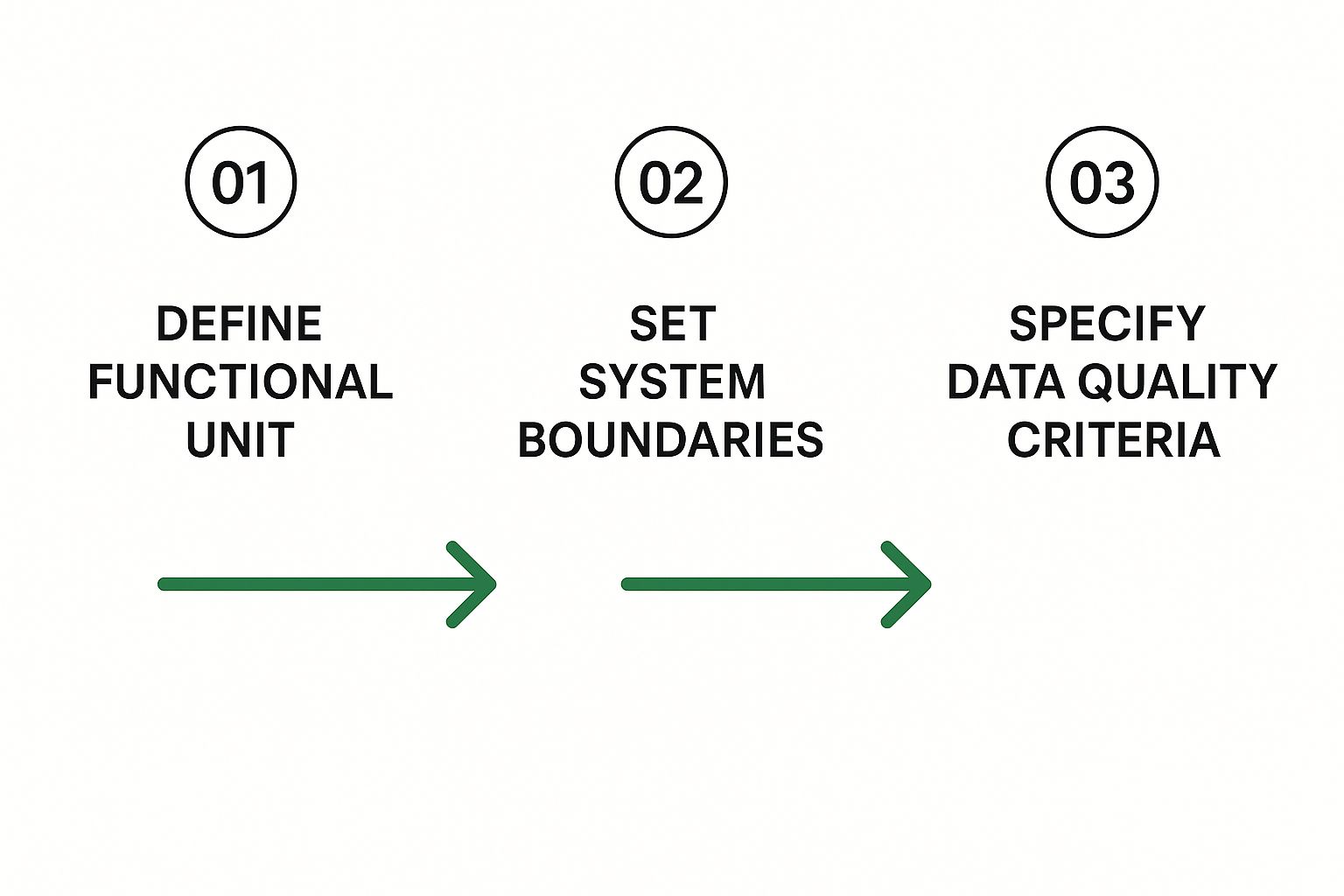

This first step is the absolute foundation of the entire assessment. Before you can even think about measuring anything, you have to be crystal clear on what you're measuring and why. It’s a bit like planning a road trip; you wouldn't just start driving without a destination and a map.

Here, you'll pin down the critical questions that will guide the rest of the study. This means defining the exact purpose of the LCA, the specific product system you’re analysing, and who the results are for. Is this for internal product improvement, a green marketing claim, or to satisfy regulators?

A crucial piece of this stage is defining the functional unit—a precise, quantifiable measure of the product's primary function. For a light bulb, for instance, the functional unit isn't simply "one bulb." It’s something more like "providing 1,000 lumens of light for 20,000 hours." This simple shift ensures you're making a fair, function-based comparison between different products that do the same job.

You also have to set the system boundaries. This is where you decide which life cycle stages and processes get included in the study. Will it be a "cradle-to-grave" analysis covering everything from raw material extraction all the way to disposal? Or a more focused "cradle-to-gate" assessment that stops once the product leaves the factory gates?

Getting this initial stage right ensures the whole study is focused, relevant, and actually answers the questions you set out to ask.

To help clarify how these stages fit together, the table below provides a quick summary of what happens in each one.

Overview of the Four LCA Stages

| Stage Name | Primary Goal | Key Activities |

|---|---|---|

| Goal and Scope Definition | To define the purpose, boundaries, and functional unit of the study. | Setting objectives, defining the product system, establishing system boundaries, selecting the functional unit, and outlining data quality requirements. |

| Life Cycle Inventory (LCI) | To collect and quantify all inputs and outputs for the product system. | Gathering data on raw materials, energy, water use, emissions, and waste for every process within the system boundaries. |

| Life Cycle Impact Assessment (LCIA) | To translate raw inventory data into potential environmental impacts. | Classifying LCI results into impact categories (e.g., climate change, water use) and calculating their potential environmental effects. |

| Interpretation | To analyse results, draw conclusions, and provide recommendations. | Identifying significant environmental "hotspots," evaluating the study's completeness and sensitivity, and presenting findings in line with the initial goal. |

Now that we have a high-level view, let's look closer at the nitty-gritty of each stage.

Stage 2: Life Cycle Inventory (LCI) Analysis

With the goals and scope locked in, it’s time for the real heavy lifting. The Life Cycle Inventory (LCI) stage is easily the most data-intensive part of the entire process. It's all about meticulously collecting and calculating every single input and output for your product system, as defined by your system boundaries.

Think of it as creating an exhaustive environmental balance sheet. For every process—from mining raw materials and shipping parts to manufacturing and final disposal—you have to account for:

- Inputs: All the raw materials, energy (electricity, fuel), water, and other resources consumed.

- Outputs: The product itself, any co-products, waste generated, and all emissions released into the air, water, and soil.

This data hunt can be a massive undertaking, often requiring you to gather information from hundreds of suppliers scattered across a global supply chain. The quality of your entire LCA hinges on the accuracy and completeness of this LCI data; it truly is the bedrock of a credible assessment.

Stage 3: Life Cycle Impact Assessment (LCIA)

Once you've collected all that raw data, the Life Cycle Impact Assessment (LCIA) stage is where you translate that long list of inputs and outputs into meaningful environmental impacts. Your inventory might tell you that 50 kilograms of CO₂ were released, but the LCIA is what tells you what that actually means for the planet.

This is where the numbers are sorted and assigned to specific environmental impact categories. Some of the most common categories include:

- Global Warming Potential (Carbon Footprint): How much the emissions contribute to climate change.

- Water Depletion: The impact on freshwater resources.

- Eutrophication: The effect of nutrient runoff on rivers and lakes.

- Acidification: The contribution to acid rain.

Essentially, this stage turns a giant spreadsheet of figures into a clear story about your product’s environmental consequences. If you want to dive deeper into how this works for emissions, our guide to calculating a product's carbon footprint is a great place to start.

Stage 4: Interpretation

The final stage, Interpretation, is where it all comes together. Here, you step back and analyse the results from the LCI and LCIA phases to draw conclusions, spot the most significant issues, and make clear recommendations.

This isn't just about presenting a bunch of numbers; it's about finding the "why" behind them. You’ll pinpoint the "hotspots"—those specific stages, processes, or materials that contribute the most to the overall environmental impact. For a t-shirt, this is the stage where you would confirm if cotton farming is, in fact, the biggest problem area.

The goal here is to deliver a clear, robust, and actionable summary that ties directly back to the original purpose of your LCA. This stage answers the ultimate question: "So what?" It provides the data-driven insights needed to make real, meaningful improvements, whether that means redesigning a product, switching suppliers, or optimising your logistics.

Why Conducting an LCA Is a Smart Business Move

It’s easy to think of a product lifecycle assessment (LCA) as just another box to tick for compliance. And while it’s great for environmental reporting, seeing it only as a regulatory hurdle means you’re missing the bigger picture. An LCA is so much more than an audit; it's a strategic tool that can make your business more efficient, resilient, and profitable.

Think of it as a detailed map of your product’s entire journey. This map doesn’t just show environmental impacts—it uncovers hidden operational weaknesses and flags opportunities you might never have noticed. It helps turn sustainability from a cost centre into a real driver of business growth.

Uncovering Hidden Cost Savings

Let’s be honest, one of the quickest wins from a good LCA is finding ways to save money. Every bit of wasted energy, excess material, or inefficient transport route isn't just an environmental problem; it's a direct hit to your profits.

An LCA digs deep and quantifies these inputs at every single stage. It might show that one particular machine on your production line is an energy hog, or that a surprising amount of raw material ends up as scrap. These are your operational "hotspots."

Once you know where they are, you can take targeted action. You might:

- Optimise machinery settings for better energy performance.

- Tweak product designs to require less material from the start.

- Source materials from suppliers who are closer, slashing transport fuel costs.

Guided by real data from your LCA, these adjustments lead to direct, measurable cost reductions that go straight to your bottom line.

Enhancing Brand Reputation and Trust

In today's market, vague claims like "eco-friendly" just don't cut it anymore. Customers, especially in the B2B world, are smart and sceptical. They want proof. An LCA gives you exactly that—credible, data-backed evidence of your commitment to sustainability.

This level of transparency is a huge marketing asset. It lets you move past generic greenwashing and make specific, verifiable claims about your product's performance. That kind of honesty builds tremendous trust and strengthens your brand with environmentally conscious consumers and partners.

A product lifecycle assessment provides the factual foundation for authentic sustainability storytelling. It allows you to confidently communicate your environmental efforts, turning your commitment into a tangible point of difference that sets you apart from the competition.

Mitigating Supply Chain Risks

Your supply chain is a complex web, and every link holds potential risks, both environmental and operational. An LCA is like a diagnostic scan, helping you spot vulnerabilities before they turn into full-blown crises.

For example, the assessment might reveal a heavy reliance on a raw material from a region facing water shortages or tightening environmental laws. This isn't just an environmental issue; it's a business continuity risk. Armed with this insight, you can start diversifying your sourcing or work with suppliers to improve their practices, making your whole operation more secure.

This proactive approach is becoming critical. According to the Czech Ministry of Environment, the country's biggest environmental burdens come from material and energy flows throughout a product's life. Their analysis shows that focusing on sustainable design and better recycling can cut a product's environmental load by 20-30% in some categories. You can read more in the Czech Republic's 2023 environmental report.

Fuelling Product Innovation

Ultimately, the insights you get from an LCA are a powerful catalyst for innovation. When your design and engineering teams understand the complete environmental profile of a product, they have a clear roadmap for what to improve. They can see exactly which materials, components, or processes have the biggest impact.

This knowledge empowers them to create the next generation of products. They can experiment with lighter materials, design things to be easily taken apart and recycled, or choose components with a much smaller carbon footprint. This data-driven process of eco-design doesn't just create more sustainable products—it often results in better, more efficient, and more competitive ones.

How Companies Apply LCA in the Real World

It’s one thing to understand the theory of a product life cycle assessment (LCA), but it’s another to see it in action. That’s where its real power shines through. Smart companies aren't just treating LCA as some box-ticking exercise; they're embedding it right into their business strategy. They use its sharp insights to make better decisions on everything from product design and material sourcing to how a product is handled at the end of its life, turning big sustainability goals into real, measurable progress.

From the packaging on supermarket shelves to the phone in your pocket, LCA is changing how industries operate from the ground up. By carefully mapping out a product's environmental footprint, these businesses are doing more than just shrinking their impact. They're building stronger, more resilient brands that connect with a market that genuinely cares.

Let's look at a few examples of how this actually works.

Optimising Packaging for a Lighter Footprint

The packaging industry is facing huge pressure to cut down on waste and switch to more sustainable materials. An LCA provides the hard data needed to stop guessing and figure out which materials and designs are genuinely better across their entire life. It helps companies compare alternatives—like glass, plastic, and plant-based cartons—on a truly level playing field.

This data-first approach is vital for backing up any green claims and driving innovation in materials. A beverage company, for instance, might use an LCA and discover something surprising. While their glass bottles are recyclable, the immense energy needed to make them and their heavy weight during transport might give them a bigger carbon footprint than a lighter carton alternative.

A product life cycle assessment cuts through the noise of "green" marketing claims by providing a scientific basis for comparison. It allows a business to prove which option is truly better for the environment, from cradle to grave.

This type of analysis is already happening right here in the Czech Republic. Tetra Pak, for example, relies heavily on Life Cycle Assessment to see how its beverage cartons stack up against options like PET and glass. Studies have shown that cartons often have a lower climate impact, mostly because they're made with a high percentage of renewable materials and are more efficient to process at their end-of-life. You can see how Tetra Pak uses certified LCA data on their sustainability reporting page.

Tackling E-Waste in the Electronics Industry

The electronics world has its own unique set of environmental hurdles. The life of a smartphone or laptop is incredibly complex, involving everything from mining for rare minerals and energy-hungry manufacturing to a high-consumption use phase and a massive end-of-life problem we all know as e-waste. For brands trying to get a handle on all these connected issues, an LCA is an essential tool.

By running a detailed assessment, an electronics company can pinpoint its biggest environmental hotspots. The results often shine a light on a few key areas:

- Component Sourcing: The extraction of raw materials like cobalt and lithium carries a heavy environmental and social price tag.

- Energy Consumption: The electricity a device uses over its lifetime can sometimes be more than all the energy used to manufacture it in the first place.

- End-of-Life: When electronics are thrown away improperly, toxic materials can leach into the soil and water.

With this knowledge, companies can take specific, targeted action. They might redesign products to use more recycled materials, engineer them to sip power instead of guzzle it, or set up robust take-back programmes to make sure components are recovered and recycled correctly. This doesn't just reduce their environmental footprint; it also helps them keep up with growing e-waste regulations. A massive part of this is tracking emissions at every stage, and our guide on mastering product-level emissions data digs deeper into that very challenge.

These examples make it clear that an LCA is much more than a simple reporting tool. It’s a dynamic guide that leads to smarter product development, backs up sustainability work with credible data, and helps companies find their way through the complex environmental demands of the modern market. By taking this holistic view, businesses are discovering innovative ways to create better products for both their customers and the planet.

Navigating Common LCA Challenges

While a product lifecycle assessment can deliver some incredibly powerful insights, let's be honest—the journey isn't always a walk in the park. Knowing the common hurdles you might face is the first step to overcoming them, turning potential roadblocks into manageable tasks.

When you approach an LCA with a clear-eyed view of these challenges, you can plan effectively, put the right resources in place, and set realistic expectations from the get-go. So, let’s break down the most frequent obstacles and talk about practical ways to handle them.

The Difficulty of Data Collection

This is, without a doubt, the biggest headache in almost every LCA. Trying to track down accurate data from every corner of a sprawling, global supply chain can feel like an impossible mission. Your suppliers might be reluctant to share sensitive information, or they may simply not track the specific details you need, like their exact energy consumption per unit produced.

To get the information you need, you have to be strategic.

- Engage Suppliers Early: Don't just send a demand for data. Treat it as a partnership. Explain why you need the information and how it helps both of you work toward shared sustainability goals.

- Provide Clear Templates: A vague request for "data" will get you nowhere. Give your suppliers simple, standardised templates to fill out. This makes it much easier for them to provide exactly what you need without the guesswork.

- Use Industry Averages Wisely: When getting primary data from a specific supplier just isn't possible, you can fall back on secondary data from established LCA databases. Think of it as a placeholder, but always make it a priority to replace it with actual figures later on.

This stage requires patience and excellent communication. At the end of the day, the quality of your LCA is only as good as the quality of the data you feed into it.

Defining Your System Boundaries

Figuring out what to include and what to leave out of your assessment—what we call setting the system boundaries—is another critical challenge. If your scope is too narrow, your results won't hold up to scrutiny. But if it's too broad, the project can quickly become unmanageable and incredibly expensive.

For example, do you need to include the carbon footprint of every employee’s commute to the factory? What about the manufacturing of the heavy machinery used to make your product? These aren't trivial questions; the answers can significantly sway the final outcome.

The key is to tie your system boundaries directly to the goal of your LCA. If you’re aiming to make a specific marketing claim, for instance, those boundaries need to be solid enough to withstand public scrutiny and avoid any hint of greenwashing.

As you work through these decisions, it's vital to properly address things like verifying compostable product claims and certifications. This ensures your claims are robust and the environmental benefits you're promoting are genuine.

Managing Complexity and Cost

Let's face it: a proper LCA can be a complex and costly exercise, especially for small to medium-sized businesses. The process often demands specialised software to crunch the numbers and experts who actually know how to interpret the results correctly.

Hiring external consultants is always an option, but their fees can be substantial. Investing in your own software is another route, but that comes with its own steep learning curve. This is where modern platforms like Carbonpunk are changing the game by automating much of the data handling and analysis, making the whole process far more accessible.

To keep these factors in check, start with a clear budget and consider a phased approach. You could begin with a "hotspot" analysis to pinpoint the most impactful areas of your product's lifecycle before committing to a full, ISO-compliant study. This gives you valuable insights without the huge initial cost. Understanding the requirements is also crucial; our detailed ISO 14067 product carbon footprint compliance guide can help clarify the standards you need to meet.

LCA's Role in a Circular Economy

If you're serious about moving away from the old "take-make-dispose" model, a Product Lifecycle Assessment (LCA) is your most important tool. The linear economy is on its way out, and the circular economy represents a much smarter, more resilient way forward.

But you can't make that shift based on guesswork. An LCA delivers the hard data you need to prove that circular strategies like reuse, repair, and recycling actually work. It shows you the real-world value of keeping materials in use for longer, turning good intentions into credible, measurable results.

Shifting from Linear to Circular

Think about a traditional linear system: once a product is thrown away, all its value is lost for good. The circular model flips this on its head by designing waste and pollution out of the picture right from the start.

An LCA is what helps you pinpoint the best circular strategy for your specific product. For a complex piece of electronics, for example, the assessment might show that a remanufacturing programme saves far more resources than just recycling the base materials. For packaging, the data could prove that a reusable system is the clear winner.

By measuring the impact of different end-of-life scenarios, a product lifecycle assessment guide helps businesses design products for circularity. It provides the "why" behind choosing repairability over disposability or modular design over a sealed unit, backing these decisions with solid environmental data.

Future-Proofing with Data-Driven Circularity

The insights you get from an LCA are exactly what you need to build effective circular economy business models. These innovative models don't just reduce your environmental footprint; they open up entirely new ways to generate revenue, which is a powerful recipe for long-term success. To get a better handle on these approaches, it's worth exploring the different circular economy business models available.

Looking ahead, the link between LCA and the circular economy is only going to get tighter. We're already seeing new developments, like integrating real-time data and AI into platforms such as Carbonpunk, which makes assessments more dynamic and easier to access. This means companies can monitor and tweak their circular systems as they go, optimising performance in real time.

For any company with its eyes on the future, mastering LCA isn't a "nice-to-have" anymore. It's a core skill needed to thrive in a world that values resource efficiency, providing the roadmap to build a truly sustainable, circular business.

Frequently Asked Questions About LCA

Let's be honest, diving into the world of product life cycle assessments can feel a bit overwhelming at first. A lot of questions tend to pop up. Here, we'll tackle some of the most common ones with straightforward answers to help you get a practical handle on what's involved.

What Does It Take to Start a Product Life Cycle Assessment?

You don't need a PhD in environmental science to get the ball rolling. The single most important thing you need to start is a clear goal. Seriously, first ask yourself why you're doing this. Are you trying to pinpoint hotspots in your production line for internal improvements? Or maybe you're aiming to make a solid marketing claim or get ahead of new regulations?

Once you know your "why," the next step is gathering the data you already have on hand. Think product design specs, manufacturing details, and shipping logs. Modern tools have made this part much less of a headache, letting you start with what you know and highlighting where the information gaps are as you progress.

How Do I Define the Scope for Different Products?

The scope is all about your product and what you're trying to achieve. It’s not a one-size-fits-all situation. For something simple, like a glass bottle, the scope is pretty straightforward: you'd look at the sand extraction, the manufacturing process, transport, how it's used, and finally, recycling.

Now, take something like a smartphone. The scope explodes in complexity. You're suddenly dealing with hundreds of tiny components, intricate global supply chains, the energy it uses over its lifetime, and what happens to all that e-waste at the end.

A crucial tip for any product life cycle assessment is to nail the "functional unit". For paint, for instance, it’s not "one litre of paint". A better unit is "protecting one square metre of wall for ten years". This simple shift ensures you're comparing real-world performance, not just physical products.

How Much Time and Resources Are Typically Required?

This is the classic "it depends" answer, but for good reason. The investment in time and money can swing wildly. A quick-and-dirty screening LCA, designed just to find the biggest environmental hotspots, might only take a few weeks and won't break the bank, especially if you're using an automated platform.

On the other end of the spectrum, a full-blown, ISO-compliant LCA that gets verified by a third party for a complex product is a much bigger undertaking. We're talking several months of work and a significant budget to cover expert consultants and deep data collection. The trick is to match the effort to your actual business needs.

Can I Use LCA Results in Marketing Without Greenwashing?

Yes, you absolutely can, but the key is to be honest and specific. To do it right, you need to ditch vague, fluffy terms like "eco-friendly." Instead, you make precise, verifiable claims that are directly supported by your LCA data.

For example, don't just say your product is "sustainable." A much stronger, more credible claim is: "Our new design cuts the carbon footprint by 15% compared to the previous model, mainly by switching to recycled aluminium." This kind of transparency builds genuine trust with your customers and gives you the hard evidence to back up your claims.

Ready to get a crystal-clear picture of your product's environmental impact? Carbonpunk's AI-driven platform handles the heavy lifting of data collection and analysis, giving you the insights needed to shrink your carbon footprint and stay ahead of regulations. Learn how Carbonpunk can transform your sustainability strategy today.