Understanding the Carbon Impact of Shipping & Logistics

Karel Maly

July 14, 2025

The carbon impact of shipping and logistics is staggering, making up a huge slice of global greenhouse gas emissions. Think about it this way: if the entire global shipping industry were its own country, it would be the sixth-largest emitter on the planet. This massive footprint is the direct result of the sprawling network of ships, planes, lorries, and warehouses that keep modern commerce moving.

Decoding Your Supply Chain's Carbon Footprint

Trying to understand your supply chain can feel like looking at a hopelessly tangled map. Goods criss-cross continents in a complex ballet of vehicles and vessels, and every single step leaves behind a carbon trail. Tracing this trail isn't just a "nice-to-have" environmental exercise anymore; it's become a core strategic and financial necessity for any modern business.

To put the scale of the challenge into perspective, the international shipping sector alone is responsible for about 3% of the world's total carbon emissions each year. That puts its environmental impact right up there with industrialised nations like Germany or Japan. It’s a sobering figure that really underscores the urgency.

Identifying the Primary Emission Sources

If you want to manage your carbon output effectively, you first have to figure out where it’s coming from. The culprits aren't just the obvious ones, like the smokestacks on a container ship or the exhaust pipe of a delivery van. The true carbon impact is woven throughout the entire journey of a product.

Here are the main sources you need to keep an eye on:

- Transportation: This is the most visible piece of the puzzle. It covers everything from ocean freight and air cargo to rail transport and the last-mile delivery lorries that arrive at your customers' doors.

- Warehousing and Fulfilment: These centres are huge energy consumers. Think about the power needed for lighting, heating, cooling, and keeping all those automated sorting systems running 24/7.

- Refrigerated Transport (The Cold Chain): Keeping goods like food and pharmaceuticals at a specific temperature is incredibly energy-intensive. This creates a significant, and often overlooked, carbon cost.

- Packaging: The creation and disposal of packaging materials, especially single-use plastics and cardboard, add a surprising amount to your overall footprint.

The real trick is that emissions are often hidden in plain sight within modern supply chains. From the electricity powering a distribution centre to the fuel burned by a ship crossing the Pacific, every single stage adds up in the final carbon calculation.

Why This Matters for Your Business

Getting a firm grip on your emission sources is the essential first step. To really decode your supply chain's carbon footprint, you need to understand the trade-offs between different transport methods. For instance, you might explore the carbon benefits of professional car shipping compared to someone driving the car themselves. Every choice you make creates a ripple effect on your environmental performance.

Beyond that, a detailed understanding helps you move from vague concerns to solid data. For any company ready to get serious about measurement, our guide on https://www.carbonpunk.ai/en/blog/carbon-accounting-for-supply-chains-explained offers a clear roadmap. Once you can visualise where your emissions are coming from, you can start building a smart strategy to reduce them—turning what seems like a liability into a genuine competitive edge.

How to Measure Your Logistics Emissions

If you want to genuinely reduce your carbon impact, you can't just guess. You have to measure it first. It's a bit like trying to manage your finances; you'd never get a grip on your spending without first looking at your bank statements. The exact same logic applies to emissions. Measuring your logistics footprint is what turns a vague environmental goal into a clear, data-driven business objective.

This whole process is about moving from abstract ideas about "being greener" to crunching specific numbers. It requires a structured approach to carbon accounting, transforming complex global standards into a practical set of tools for your business.

Understanding the Emission Scopes

The first thing you need to get your head around is where your emissions are actually coming from. The globally recognised Greenhouse Gas (GHG) Protocol gives us a fantastic way to do this by splitting emissions into three "scopes." This framework helps you separate what you control directly from what you merely influence.

- Scope 1 Emissions: These are the direct emissions from sources your company owns or controls. Think of the exhaust fumes from your own fleet of delivery lorries, your company cars, or any fuel you burn on-site at your facilities. It's the stuff you're directly responsible for creating.

- Scope 2 Emissions: This covers indirect emissions from the energy you buy. We're mainly talking about the electricity used to power your warehouses, distribution centres, and offices. You don't produce these emissions yourself, but your consumption causes them.

- Scope 3 Emissions: Now, this is the big one. Scope 3 is the most complicated and, for most businesses, the largest category. It includes all other indirect emissions happening across your entire value chain. This means emissions from third-party logistics (3PL) providers, any transport you hire but don't own, and even the manufacturing of the goods you're shipping. For most companies, the carbon impact of their shipping and logistics falls squarely into this scope.

For most companies, Scope 3 emissions can account for over 70% of their total carbon footprint. This makes accurately measuring the emissions from your outsourced shipping and logistics partners absolutely critical for a credible sustainability strategy.

Gathering the Right Data

Once you understand the scopes, you need to start collecting the right data. It's like gathering ingredients for a recipe; if you miss a key component or get the measurements wrong, the final dish just won't work. For every shipment, you need a few specific data points.

To help you pinpoint where to look, here's a table breaking down the primary emission sources across the logistics journey.

Primary Emission Sources in Logistics and Shipping

This table breaks down the main contributors to carbon emissions across different stages of the supply chain, helping businesses identify key areas for reduction efforts.

| Logistics Stage | Primary Emission Source | Key Contributing Factors |

|---|---|---|

| First-Mile | Road Transport (Lorries, Vans) | Fuel combustion (diesel, petrol), vehicle efficiency, route optimisation, load factor. |

| Warehousing | Energy Consumption | Electricity for lighting, heating, cooling, and operating machinery (forklifts, conveyors). |

| Long-Haul (International) | Ocean Freight & Air Freight | Fuel combustion (marine gas oil, jet fuel), vessel/aircraft size and age, trade lane, port congestion. |

| Long-Haul (Domestic) | Rail & Road Transport | Fuel combustion, locomotive/engine type, track infrastructure, empty miles. |

| Last-Mile Delivery | Vans & Light Commercial Vehicles | Fuel combustion, high number of stops, urban traffic congestion, failed delivery attempts. |

| Packaging | Manufacturing & Disposal | Energy used to produce materials (cardboard, plastic), transport of packaging, end-of-life emissions. |

Getting a handle on these specific sources is the first step toward making meaningful, targeted reductions in your overall footprint.

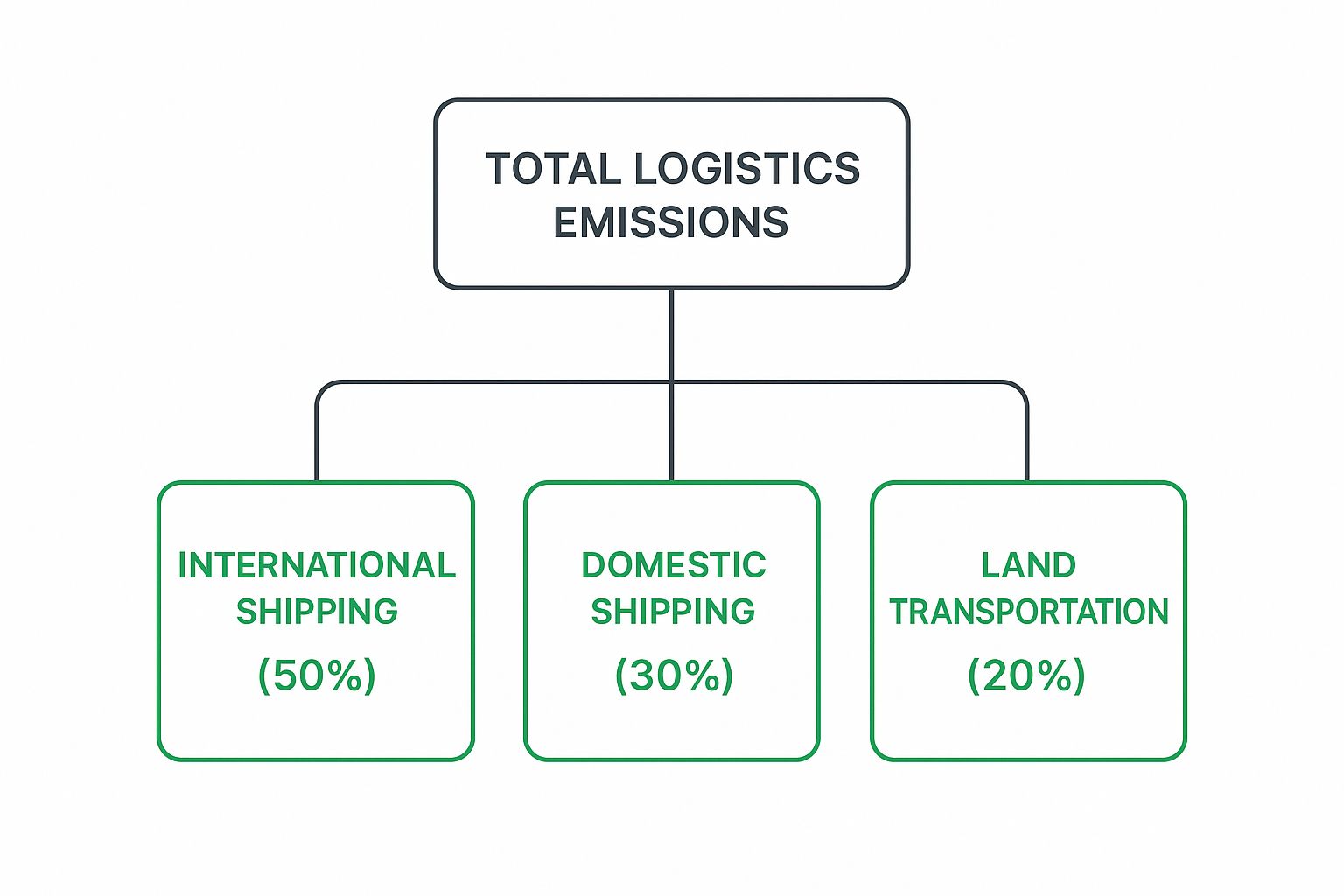

This infographic also helps to visualise where logistics emissions often come from, showing just how significant international and domestic shipping can be.

As you can see, international shipping often represents the lion's share of a company's logistics footprint. That makes it a priority area for both measurement and, later, reduction efforts.

Here are the key data points you'll need to collect:

- Transport Mode: Was it sent by air, sea, rail, or road? Each mode has a wildly different emissions factor.

- Distance Travelled: The total kilometres from its origin point to the final destination.

- Shipment Weight and Volume: Heavier and larger shipments simply need more fuel to move, which directly pushes up emissions.

- Fuel Type and Consumption: What kind of fuel was used (e.g., diesel, marine gas oil, sustainable aviation fuel), and how much of it was burned?

Applying a Measurement Framework

With your data in hand, you need a consistent way to turn it into a final emissions figure. The GLEC Framework (Global Logistics Emissions Council) is the industry-leading methodology for this. Think of it as a universal "carbon calorie counter" for logistics. It provides standardised emission factors for different transport modes, vehicle types, and even specific regions.

Using a framework like GLEC ensures your calculations are credible and line up with global best practices. This is important for context. For instance, the carbon impact of shipping and logistics in the Czech Republic fits into a national picture where transport emissions are a major focus. The country, which produced 114 million metric tonnes of CO2 equivalent in 2021, aims to boost renewable energy in transport to 14% by 2030 as part of its Clean Mobility action plan. A global standard like GLEC helps you understand how your company's emissions fit into these broader national and international goals. You can discover more about the EU's environmental policy context689329_EN.pdf) for a wider view.

By breaking the process down—understanding the scopes, gathering the data, and applying a framework—measuring your logistics emissions stops being an impossible puzzle and becomes a manageable task. This data is what empowers you to set realistic targets, meet growing customer demands for transparency, and ultimately build a more resilient and sustainable supply chain.

The Key Levers That Control Your Carbon Output

Think of yourself sitting in a control room for a moment. You're surrounded by levers and dials, and each one adjusts a different part of your supply chain's final carbon output. Getting a real handle on your logistics footprint means knowing which levers to pull, and in what combination, to make a meaningful difference.

Some of these controls are big and obvious—like choosing between a cargo plane and a container ship. Others are far more subtle but just as powerful, like fine-tuning a delivery route or rethinking your warehouse layout. The goal is to first recognise all the levers you have at your disposal, then learn how to use them effectively.

Without a doubt, the most significant lever you can pull is the one that controls how your goods actually get from A to B. The carbon impact of your entire logistics operation is overwhelmingly weighted by your choice of transport, simply because the difference in emissions between modes is so dramatic.

Choosing Your Transport Mode Wisely

You can think about your transport options on a spectrum, with speed at one end and environmental cost at the other. Air freight sits at one extreme: it's incredibly fast, but it's also the most carbon-intensive choice by a long shot. At the other end, you have sea and rail, which are much slower but far more efficient for moving large quantities of goods over long distances.

- Air Freight: The express option, but it comes with exceptionally high emissions per tonne-kilometre. You really want to reserve this for only the most urgent, high-value shipments where speed is genuinely non-negotiable.

- Sea Freight: This is the backbone of global trade for a reason. It's one of the most carbon-efficient ways to move bulk goods across continents. While it’s responsible for around 3% of global emissions because of its sheer scale, its efficiency per item is incredibly high.

- Road Transport: Unbeatable in its flexibility, road is essential for the first and last miles of almost any journey. Its emissions, however, can vary wildly depending on the vehicle type, fuel, and load factor. A fully loaded lorry is a world away from a half-empty one in terms of efficiency.

- Rail Freight: For moving heavy, bulky goods across land, rail is an excellent low-carbon alternative to road transport. It's especially effective for long-haul domestic or cross-border routes and can slash your carbon footprint compared to lorries.

The decision to ship a pallet of goods by air instead of by sea can increase its carbon footprint by a factor of 40 or more. This single choice often has the largest immediate impact on your logistics emissions.

Understanding this trade-off is the first real step toward change. For instance, if your business can get better at planning inventory needs further in advance, you can deliberately shift from relying on last-minute air freight to more scheduled sea or rail shipments. That one change can lead to massive carbon savings.

The Impact of Weight, Distance, and Density

Looking beyond the mode of transport, three simple physical factors directly influence how much fuel is burned: weight, distance, and volume. It’s common sense, really. Heavier and bulkier shipments require more energy to move, and the further they travel, the more fuel they consume.

This is exactly where shipment consolidation becomes such a powerful strategy. By combining multiple smaller shipments into a single, larger load, you boost the load factor—the percentage of a vehicle's capacity that’s actually being used. This simple act drastically improves fuel efficiency.

A lorry that's completely full has a much lower carbon footprint per item than one that's only half full. This brings us neatly to a major source of hidden emissions in the logistics industry: "empty miles."

Tackling Empty Miles and Route Optimisation

"Empty miles" is the industry term for any distance a vehicle travels without carrying cargo. Most often, it's the return journey after a delivery has been made. It represents a pure waste of fuel, money, and carbon capacity—a massive systemic inefficiency.

This is a problem that smart route optimisation software is designed to solve. By planning multi-stop routes or finding "backhaul" opportunities (where a lorry picks up a new load for its return trip), you can minimise this waste. The result isn't just a slashed carbon output but also significant cost savings.

Finally, the energy drain from warehousing and fulfilment centres is another important lever. These facilities consume enormous amounts of electricity for lighting, climate control, and all the automated machinery. Simple changes like switching to energy-efficient lighting, installing solar panels, or even optimising the warehouse layout to reduce how far forklifts have to travel can all lower your carbon footprint. Every small adjustment adds up.

Actionable Strategies for Greener Logistics

Knowing where your carbon emissions come from is one thing; actually doing something about them is another beast entirely. This is where the rubber meets the road—turning theory into real-world action. Tackling the carbon impact of shipping and logistics isn't about one magic bullet; it's about a smart mix of quick wins and long-term strategic changes.

The great news? Most of these strategies don't just shrink your environmental footprint. They often lead directly to cost savings and a tougher, more efficient operation. It’s that rare win-win, where what’s good for the planet is also genuinely good for your bottom line.

Optimise Your Transport and Consolidation

The fastest way to make a real dent in your emissions is to get smarter about how you use your vehicles. This all starts with better route planning and a relentless focus on getting rid of wasted space.

Picture a half-empty lorry chugging down the motorway. It’s burning nearly the same amount of fuel as a full one but delivering a fraction of the value. That's where shipment consolidation becomes your best friend. By grouping smaller orders into a single, larger shipment, you push the load factor of every vehicle sky-high.

On top of that, modern routing software can be a game-changer. It helps you:

- Slash "empty miles" by finding backhaul jobs, so lorries aren't making return trips with nothing but air in the back.

- Map out the most fuel-efficient routes, taking into account everything from traffic jams to steep hills and tight delivery windows.

- Cut down on failed deliveries—which mean extra trips—by simply improving communication with the final customer.

Make the Strategic Shift to Lower-Carbon Modes

While optimising your current setup brings immediate gains, the biggest long-term wins come from moving away from the most carbon-heavy ways of transport. This takes more planning, but the payoff is huge.

For instance, nudging a shipment from air freight to sea or rail can slash its emissions by over 90%. Yes, this often means tweaking your inventory planning to handle longer lead times, but the environmental and financial rewards are hard to ignore. Even something as simple as offering customers a "green shipping" option at checkout—slower, but cheaper and with a lower carbon cost—can shift demand in the right direction.

You can also look into proactive programmes like carbon neutral shipping initiatives to offset the emissions you can't avoid. These typically involve investing in certified carbon reduction projects to balance out the impact of your shipments.

Greening Your Warehouses and Fulfilment Centres

The carbon story doesn't end when the lorry engine switches off. Warehouses and distribution centres are massive energy hogs, but they're also ripe with opportunities for savings.

Your warehouse is more than just a storage space; it's an energy hub. Transforming it into a sustainable facility reduces both your operational costs and your Scope 2 emissions, making it a critical part of any green logistics strategy.

Here are a few high-impact upgrades to consider:

- Energy-Efficient Lighting: Just swapping old fixtures for LEDs can cut your lighting electricity bill by up to 75%.

- On-Site Renewables: That massive, flat warehouse roof is perfect for solar panels, which can generate a huge chunk of the building's energy needs.

- Smart Climate Control: Use automated systems to heat and cool only the areas that need it, when they need it, putting an end to wasted energy.

This is especially relevant for businesses operating in regions like Central Europe. Take the Czech Republic, a landlocked country heavily reliant on overland transport from major European ports. The emissions embedded in goods arriving from these hubs form a key part of the nation's total logistics footprint. It's a complex picture, but it highlights how every part of the journey matters.

Rethink Your Packaging

Finally, don't forget about the box itself. Smarter packaging is a surprisingly powerful way to cut your carbon footprint. This goes beyond just using recycled materials; it’s about ruthlessly cutting weight and volume.

Lighter, smaller packages need less fuel to move and let you cram more products into a single vehicle, boosting that all-important load factor even further. Getting rid of empty space with void-fill, switching to custom-sized boxes, and choosing lightweight, sustainable materials all add up to a greener journey for every item you ship.

For a deeper dive into this and other practical steps, check out our expert strategies to reduce supply chain carbon emissions.

Navigating the New Rules of Emissions Reporting

The world of logistics used to be simple: get something from point A to point B. Now, it’s wrapped in a growing web of environmental rules. For any business that moves goods, this isn't just background noise—it's a massive shift that directly impacts your costs and competitiveness.

Think of this as more than just a legal summary. It’s a strategic heads-up on the new reporting demands, carbon taxes, and border tariffs you need to get ahead of. Getting this right isn't just about compliance anymore; it’s about protecting your supply chain and finding a powerful business advantage.

Understanding the EU's New Regulatory Framework

Two major EU laws are completely changing the game for the carbon impact of shipping and logistics. They put a real price tag on emissions and require a whole new level of transparency from companies.

First, maritime shipping is now part of the EU Emissions Trading System (ETS). The easiest way to think of the ETS is as a "cap and trade" system. The EU sets a total limit (the cap) on emissions, and companies need to buy allowances for every tonne of CO2 they release. For shipping, this means vessel operators must purchase and hand over these allowances, turning their carbon output into a direct financial cost.

This isn't some far-off problem. The EU ETS for shipping started its rollout in 2024. The cost of carbon is already being baked into shipping rates, affecting every business that moves goods by sea into, out of, or between EU ports.

The second major policy is the Carbon Border Adjustment Mechanism (CBAM). In simple terms, this is a carbon tariff slapped on certain goods imported into the EU. The main goal is to stop "carbon leakage," which is when a company just moves its factory to a country with lax environmental laws to avoid costs.

What CBAM Means for Your Supply Chain

CBAM forces importers to report the "embedded" emissions in the products they bring into the EU. Soon, they'll have to buy special CBAM certificates to cover those emissions, making sure the carbon price for imported goods matches what EU producers pay.

Right now, the key categories affected are:

- Iron and steel

- Aluminium

- Cement

- Fertilisers

- Electricity

- Hydrogen

If your supply chain touches any of these materials, getting ready for CBAM reporting is non-negotiable. Having accurate data on the emissions from production and transport is no longer just for your own reports—it's your ticket to enter the EU market. For many businesses, particularly smaller ones, this creates a huge data-gathering headache. Our essential guide on carbon emissions reporting for SMEs can help you get prepared.

These new regulations are a direct result of ambitious national climate goals. Take the Czech Republic, for example. To hit its national targets—a 14% emissions reduction by 2030 and climate neutrality by 2050—it has to tackle emissions from every sector, including transport. Policies that target the carbon footprint of logistics are a critical piece of that puzzle. You can discover more insights about Czech decarbonisation pathways to see the bigger picture.

Surviving in this new environment means going beyond just ticking boxes. It's about building a resilient and transparent supply chain that can turn these challenges into a source of customer trust and a genuine competitive edge.

The Future of Sustainable Supply Chains

Let's be clear: managing the carbon impact of shipping and logistics isn't a side project or a passing trend anymore. It's now a core part of how smart businesses operate, marking a permanent shift in strategy. The companies that will thrive in the coming years are those that see decarbonisation not as a chore, but as a direct path to innovation, a more resilient business, and a genuine competitive edge.

This future isn't some far-off concept; it's already taking shape. We're on the verge of seeing electric and hydrogen-powered lorries become common on our roads, while sustainable aviation fuels (SAFs) are set to slash the massive footprint of air freight. These aren't just ideas on a drawing board; they are the next practical frontier for logistics.

The Dawn of Hyper-Efficient Logistics

So, what's the biggest driver of this change? It's the smart application of data analytics and artificial intelligence. AI is set to build incredibly efficient, low-carbon supply chains by going way beyond simple route planning. It will enable predictive logistics—spotting potential disruptions before they happen, fine-tuning inventory to eliminate wasteful shipments, and even choosing the most carbon-friendly transport option on the fly.

The real aim here is to create an intelligent, self-correcting logistics network. We're talking about a system where efficiency and sustainability aren't at odds. Instead, they are woven together, guided by data at every single stage.

This intelligent approach naturally spills over into your business relationships. You can't build a truly sustainable supply chain alone; it requires deep collaboration with your partners. Knowing how to cultivate strong, transparent relationships is fundamental to hitting your environmental targets. This skill is so crucial that entire guides are dedicated to Mastering Supplier Relationship Management.

Ultimately, the journey forward is about taking control. The tools and technology needed to make a real, measurable dent in your logistics footprint are here today. By embracing them, your business won't just survive in a world that demands sustainability—it will secure its place as a resilient, forward-thinking leader in your industry.

Your Top Questions About Logistics Emissions, Answered

As businesses get serious about their environmental impact, a lot of questions pop up around shipping and logistics. Let's tackle some of the most common ones with straightforward, practical answers.

Is It Better For The Planet If I Return Something, Or Just Keep It?

From an environmental standpoint, keeping the item is almost always the better choice. When you return something, you trigger what’s known in the industry as reverse logistics, and it essentially doubles the product's shipping footprint. The item has to travel all the way back to a warehouse, using more fuel and often requiring brand-new packaging.

What's really surprising is that a huge number of returns never see a shelf again. It can be more expensive for retailers to inspect, clean, and repackage an item than it is to just throw it away. In 2022, a staggering 9.5 billion pounds of returned goods in the US were sent directly to landfill, generating a massive amount of waste and emissions for nothing.

When you return an online purchase, you're not just sending an item back—you're kicking off a carbon-intensive journey. This trip can generate up to 24 million metric tons of CO2 annually and often ends with the product being thrown away.

How Can I Find A Truly Sustainable Shipping Partner?

Finding a genuinely sustainable shipping partner means looking past the green-tinted marketing. A logistics provider who is truly committed will be open and honest about their environmental data and what they’re actively doing to improve.

Here are a few things to dig into when you're vetting potential partners:

- Hard Data: Can they give you specific emissions data for your shipments? Ask if they use a recognised standard, like the GLEC Framework, for their calculations.

- Modern Fleet: Are they putting their money where their mouth is by investing in electric lorries, cargo bikes, or ships that run on cleaner fuels?

- Smarter Operations: What are their strategies for optimising routes? How do they ensure their vehicles aren't travelling empty on return trips (a problem known as "empty miles")?

- Credible Certifications: See if they hold any third-party environmental certifications or take part in respected industry sustainability initiatives.

A partner with concrete data and a clear action plan is always a better bet than one who just offers vague promises about being "green."

Is Carbon Offsetting A Real Solution?

Carbon offsetting can play a role, but it’s more of a final piece of the puzzle than a get-out-of-jail-free card. The idea is to balance out the emissions you can't avoid by investing in projects that remove or prevent greenhouse gases, like planting forests or funding renewable energy.

But here's the key: offsetting should always come last. Your first and most important job is to reduce your actual emissions wherever you can. That means making your operations more efficient, choosing smarter shipping modes, and optimising every step. Only then should you use offsets to deal with the small, unavoidable footprint that remains.

Ready to turn emissions data into a competitive advantage? Carbonpunk provides an AI-driven platform to automate the tracking, analysis, and reporting of your supply chain emissions with over 95% accuracy. Take control of your carbon footprint today.